Ultimaker has released beta version 5.0 of their flagship software system, Ultimaker Cura.

The software is used by the Ultimaker operators to manage and control their fleets of Ultimaker equipment, including job preparation and file management.

Because Ultimaker chooses to open source Ultimaker Cura code, it is also used by a vast number of other non-Ultimaker 3D printer manufacturers as their job preparation software. Ultimaker strongly supports this, as they even include printer configuration for dozens of alternative machines in the default software distribution of Ultimaker Cura.

Because of that, Ultimaker Cura is a critical piece of infrastructure for the 3D print world. Any significant change to the product will affect not only Ultimaker, but countless others around the world.

Today Ultimaker announced an entirely new version of Ultimaker Cura, 5.0.

How important is this release? Ultimaker CTO Miguel Calvo said:

“Ultimaker Cura 5.0 represents the biggest leap forward in print quality that the software has ever seen. This is the start of a true revolution in 3D printing technology. We believe that even those who have looked at 3D printing before and concluded that it may not be ready for their use, today it is time for them to look again. Until now, you had to make your design work for 3D printing. It’s time to turn the table… from designing for 3D printing, to 3D printing for design.”

That’s quite a statement. But what is it that makes version 5.0 so different?

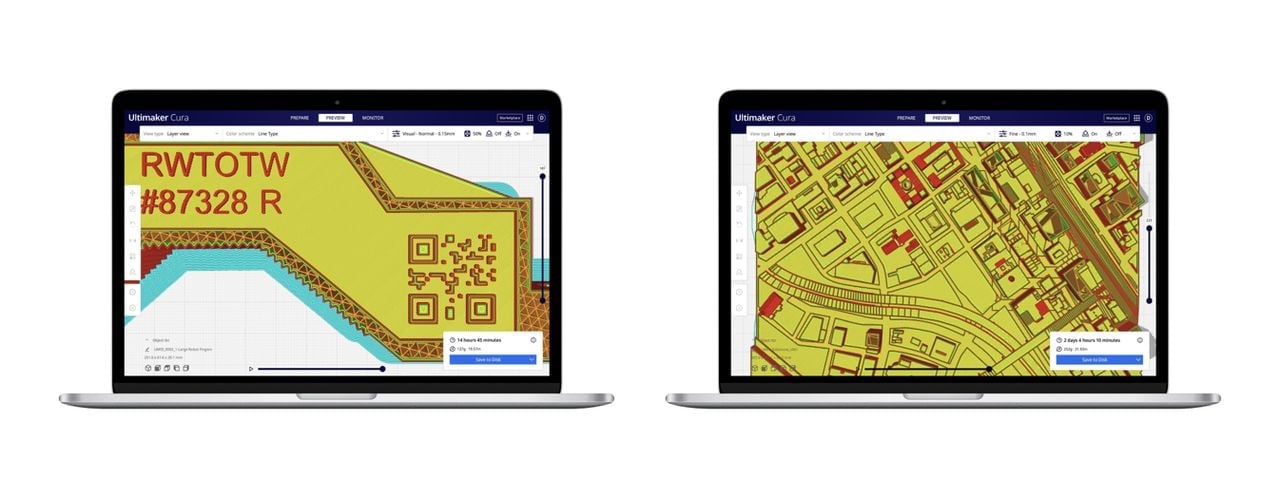

The new version improves the user interface, as is customary on new releases, and also provides support for the new M1 chip in modern Macs. They’ve also added new print profiles for Ultimaker equipment that apparently speeds printing by up to 20%. But the real deal is the completely new slicing engine.

Code named “Arachne”, it has been experimentally tested for quite a while, and recently hinted at being included in 5.0.

The big change with the new slicing engine is how it handles gaps in 3D prints. Normally FFF 3D printers have a bit of an issue when building thin walls: the extrusion wide is not always a perfect multiple of the wall width.

This means there will almost always be a small gap somewhere inside the print, lessening the strength of the part because the walls are not completely solid. Virtually ever FFF 3D printer has this issue, and it has basically been ignored until now.

The new slicing engine detects and deals with these pathological thin wall scenarios by dynamically adjusting the material flow to nearly fill these gaps.

Remember that thin walls are not just “thin walls”. Any part of the geometry that is thin could benefit from this new system. The result is that the more complex printed parts should all be stronger.

Now that the software is in beta state, it is available for download and testing by anyone at the link below. However, do take note that it is still “beta”, meaning it is not quite yet the production release. There could be bugs so use the new software with caution — and report any you find to Ultimaker.

Via Ultimaker Cura