In an unusual online announcement, Ultimaker revealed an upcoming cleaning station.

The company now bills itself as the “number one maker of professional 3D printers”, and they’re likely correct on that count. They’ve fully transformed from the hobbyist background from their launch, some ten years ago.

Now the company markets equipment for professionals in various industries and corporate environments. Their strategies to get there have been quite effective. For example, one strategy they used in the past was to offer equipment that automatically “found” each other on a company’s internal network to set up a 3D print workgroup. While that might seem like a simple technical feature, in practical terms it allowed a department to buy a workgroup of 3D printers without having to involve the IT department. For those in corporate environments, you know what that usually means.

It’s this style of detailed approach that seems to have been Ultimaker’s key to success. They carefully look at their clients and attempt to overcome their challenges.

In the past year they’ve tried to solve the problems of inconsistent materials by launching a materials profile database directly connected to their Ultimaker Cura slicing software. This allowed operators to safely buy known materials and use them immediately using pre-tested print parameters. That service saves a considerable amount of time for operators, who no longer need to undertake trial and error projects to identify the best print parameters.

This week Ultimaker continued with this pattern by identifying another need: PVA removal.

PVA is a water soluble material often used as a support material for very complex 3D prints. Normal “solid” support structures are incredibly tedious to remove manually, and sometime cannot be removed at all because they are embedded inside a complex geometry. Meanwhile, soluble supports simply dissolve away, without requiring any labor at all.

Or so the theory goes.

It turns out that’s not always the case, according to users of Ultimaker’s dual-hot end equipment that’s typically used with PVA soluble support.

While you might expect the model to come out perfect from a pail of water it was immersed in after printing, that did not always happen. Some blobs of squishy PVA usually remained, as well as a sticky residue that had to be manually cleaned.

Here we have another customer workflow barrier that Ultimaker wants to eliminate. That’s the reason behind the announcement of their new PVA Removal Station.

It’s an accessory that can clean PVA supports away far more reliably and quickly. It requires 13.5L of water and automatically circulates in different directions to completely remove PVA and residue in about 3-4 hours. It also includes a sensor to indicate if the water requires replacement after many cleanings.

The small unit is also made with a transparent frame so that the operator can see if the dissolving process has been completed. However, I suspect the water may become cloudy after multiple cleanings.

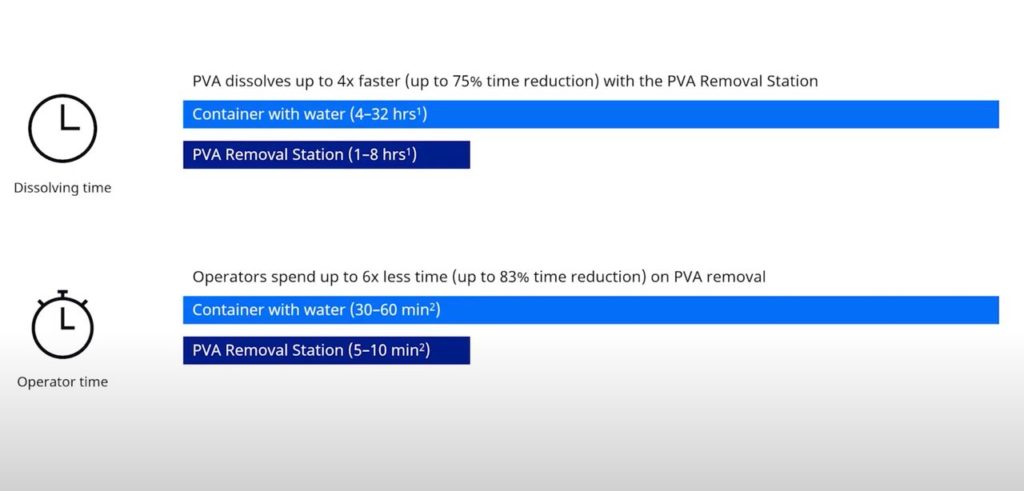

Ultimaker said the device can clean PVA in 4X less time, and do a better job than stationary water containers. Because it does such a good job, there is less manual labor required by the operator to complete the cleaning.

Ultimaker said the new PVA Removal Station will be available in the first half of 2022.

Via Ultimaker