There’s a new document from UL describing how to work with 3D printers in a safe manner.

Officially, the document is targeted at educational institutions that might be using 3D printers on campus, but the procedures described are absolutely usable by anyone with a 3D printer.

The lengthy 45 page document, entitled, “Safe Use of 3D Printing for Institutions of Higher Education”, is laid out in official form, with plenty of administrative portions. However, they do describe in detail the two main types of 3D printers covered by UL 200B: filament extrusion and vat polymerization (which covers SLA and MLSA devices).

They performed an interesting survey of major educational institutions and found that, unsurprisingly, most of the 3D printers are placed in makerspaces, labs and design spaces, while there are fewer placed in libraries, classrooms and offices.

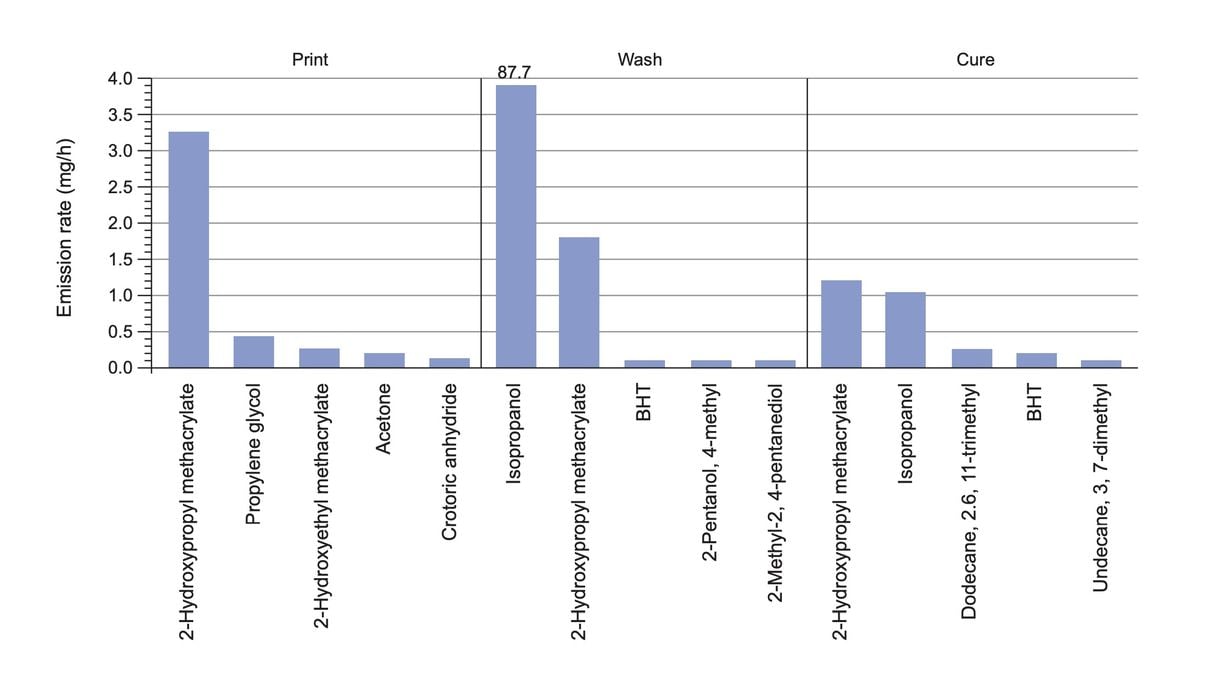

The report describes in detail the nature of the threat from 3D printing in both modes, which are essentially human exposure to nanoparticles and a variety of noxious VOCs (volatile organic compounds.) For example, here is a chart of the specific chemicals found to be issued when using vat polymerization 3D printing processes:

As you can see in the chart, the major exposure is to 2-hydroxypropyl methacrylate, the active ingredient in most 3D printing resins. This chemical is released into the air during printing, but also during the cleaning stage where it mixes with the IPA solvent. Notably, the biggest single chemical releases is isopropanol.

There is a huge amount of detail in the report, including a considerable discussion of ventilation requirements and location choice for the 3D printers. We’ve always recommended use of ventilation, but here UL 200B describes what is required in significant detail

The report recommends following 3D printer manufacturers’ recommendations, which goes without saying. The meat of the report is in fact the additional recommendations that go beyond what typical 3D printer manufacturers recommend.

UL 200B covers best practices for the two processes before, during and after printing, as well as post processing, waste handling and storage. This is important, as chemicals tend to exist beyond just the printing stage and must be dealt with appropriately.

There is a section on how to develop a risk management program for the institution, which I strongly encourage. However, individuals operating 3D printers might not require such a program.

I encourage everyone involved in 3D printing read UL 200B and strongly consider its recommendations and procedures. While you might use a 3D printer with no apparent issue, the problem is that these chemicals are cumulative and effects may appear only in the long term. The best practice is to proceed carefully and follow UL 200B’s recommendations for the safest environment possible.