Charles R. Goulding and Preeti Sulibhavi look at the recent increase in U.S. military production and how 3D printing takes a strong role.

With the war raging in Ukraine over the Russian invasion since February 2022, there have been a number of defense packages sent to Ukraine in recent months and weeks. The defense packages include funding for highly advanced military equipment. As of the writing of this piece, the U.S. has provided approximately US$10B in defense funding to Ukraine.

Some of the equipment funded through the defense packages sent to Ukraine include products being supplied by Lockheed and Raytheon.

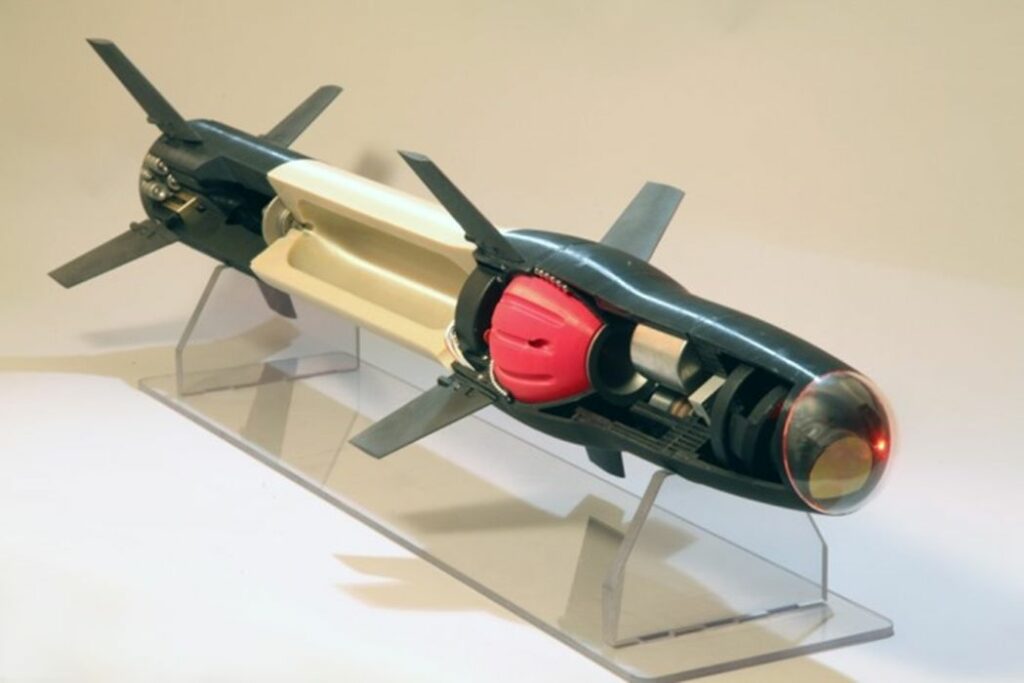

Lockheed has seen a substantial reduction in time and costs associated with flight simulators. 3D printing their simulators reduced their costs by US$3M. In addition, components of missile systems that can be 3D printed include rocket engines, fins, and parts for guidance and control systems among many others.

Engineers are exploring the use of 3D printing to lay down conductive materials for electrical circuits, create housings for the company’s revolutionary gallium nitride transmitters, and fabricate fins for guided artillery shells.

3D printing reduces costs associated with traditional manufacturing, such as machining of parts. It allows for quick design and rapid changes because engineers only need to change the digital model representing each part. As long as they stay within set parameters, they can have new parts in hours instead of weeks.

The Ukraine war re-established the need for conventional armaments much of which are no longer in defense contractor OEM inventory. The leading OEMs have asked the Department of Defense (DoD) to provide minimum pressing needs so that they can commit to recruiting these products.

We have covered the redistribution of aerospace suppliers to submarines in terms of converting Boeing supply chains to Electric Boat submarines for defense purposes.

Drones, or unmanned aerial systems, are another highly useful item the U.S. is sending over to Ukraine. They can be utilized in many scenarios without risking human life.

There are many ways that 3D printing can play a part in the various defense packages of funding to Ukraine. Whether it is for naval components for equipment, drones, or ships as either prototypes or even replacement parts, there is room for 3D printing to grow in this area.

In a July 20th, 2022, webinar sponsored by the Additive Manufacturing (AM) Coalition, covering the Military Policy of AM, the role of additive manufacturing in current defense strategy was discussed. The speakers were Jim Monroe, Senior Director, SPEE3D, Ms. Rachael Andrulonis, Director of Advanced Materials Research and Senior Scientist at Wichita State University, National Institute for Aviation Research (NIAR), and Dr. Arun Seraphin, Director, Emerging Technologies Institute, National Defense Industrial Association. Each discussed the role their departments play and how AM is a part of that strategy.

SPEE3D has won the inaugural expeditionary and tactical 3D printing excellence award from the U.S. Defense Strategies Institute for deployable AM.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

With these military aid packages come opportunities for defense contractors and manufacturers of military equipment to utilize 3D printing to save on costs and time.