Twikit launched a new automated lattice tool they call “Laddy”.

The Belgian company has built a cloud platform that’s designed to support the idea of mass customization, where bespoke products can be produced on demand using 3D printing and other technologies. They explain their approach:

“Twikit created its proprietary software which creates the bridge between the user experience of customization and digital manufacturing 4.0. It enables the on-demand production of personalized products at scale. The technology results in an end-to-end solution and can be seamlessly integrated within legacy systems for digital manufacturing environments such as 3D-printing, laser cutting, and CNC milling.”

Currently they have clients offering customized products in several industry segments, including sportswear, automotive and orthotics. As you can guess, each of these could benefit from a personalized design that might be able to match a person’s body shape. That’s what mass customization is all about.

But this week Twikit announced Laddy, the new feature in their cloud platform. This is a lattice-generating system.

Lattices are an incredibly important feature in 3D printing because their complex structure allows the creation of lightweight, lower-material objects that are as fully functional as their “solid” equivalents. Also, lattices are easily produced using 3D printing, while they are extraordinarily challenging to make with conventional tooling. In other words, ingenious use of lattices can unlock the full potential of 3D printing.

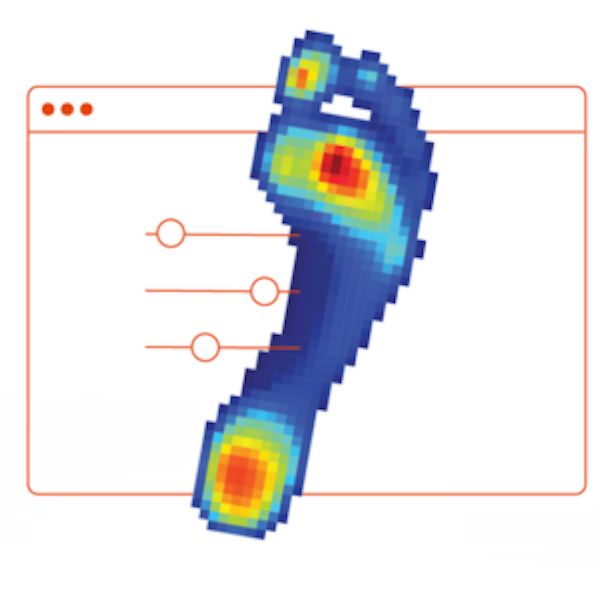

That’s the intention behind Laddy: it allows a Twikit system to generate a lattice for a specific request based on input data. An example might be for an orthotic implant: the user scans their foot, and a matching lattice-based orthotic 3D model is generated.

Hold on, isn’t that an easy thing to do? Well, yes it could be if you simply generate a uniform lattice — that can be easily done in many CAD systems. But there’s a big difference with Laddy, which generates “intelligent” lattices.

A big advantage with lattices is that they need not be uniform; they could conform to a mechanical model that varies the strength of the lattice from place to place. This approach is far more sophisticated and can be used to create “lattices with a purpose”.

Twikit explains how Laddy develops this type of lattice:

“Laddy’s AI core learns how to transform the custom input into the ideal lattice for each application (e.g., shoewear, helmets, saddles). The solution decides where specific unit cells should be located, their dimensions, and their strut thickness to automatically generate a lattice with the required mechanical properties.”

As I see this, a vendor could start with a base 3D model of a product, and then apply a customized lattice to it, having been generated from buyer input. Then it’s simply a matter of 3D printing the resulting 3D model and you’ve created the customized product for shipment.

Lattices have revolutionized several industries, but as far as I know the technology has not been made available for individual product production until now.

I’ve said previously that once consumers adopt the idea of personally customized products, there will be a dramatic rise in use of 3D printing. Twikit could be one of the companies helping make that transition.

Via Twikit