I’ve been looking at trinckle’s Fixture Designer software, and it’s quite impressive.

trinckle is the producer of Paramate, specialized software to simplify 3D print workflows, particularly for creating custom objects. Their technology is based on the idea of generative design, where users specify a few parameters and the system creates a 3D model automatically. This is perhaps why the software is named “Paramate”.

In the past they’ve used the system to enable customers to rapidly create end effectors for robotic systems, which are frequently changed up as factories switch modes. Paramate allows operators to click through a sequence to rapidly create a new 3D model for the end effectors, keeping the factory going at full speed.

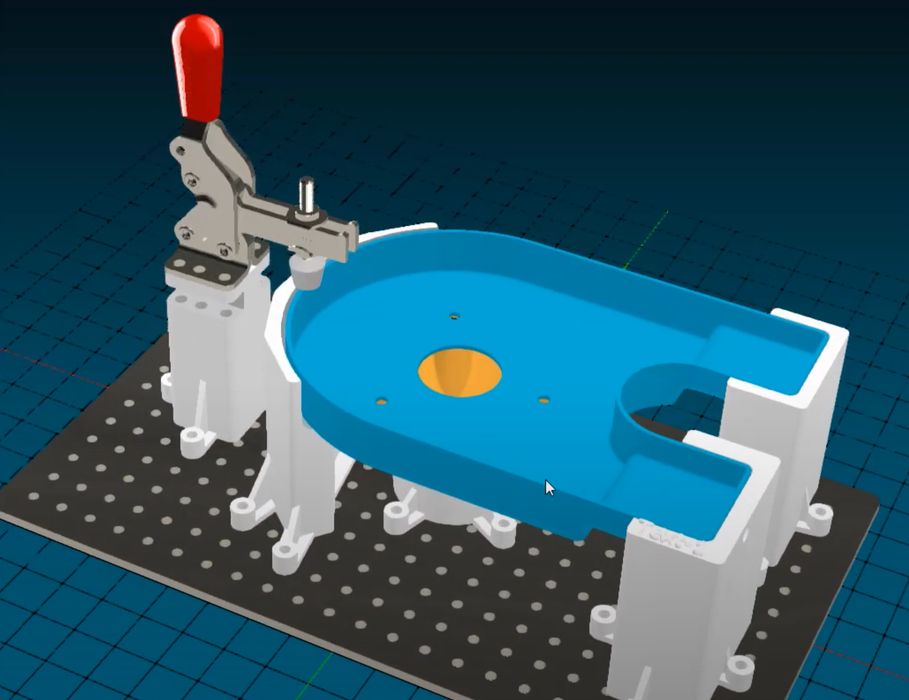

One of the latest features in Paramate is a very interesting capability: fixtures. The Fixture Designer is a focused tool that allows the user to rapidly create fixtures. These are custom objects that hold an item firmly in place, typically during assembly or other factory operations.

Fixtures are incredibly important, because they ensure quality and speed of assembly. It’s like having another set of hands helping the worker (or robot) place items exactly where they should be.

While fixtures are extensively used in industry today, the creation of the fixtures is perhaps too complex. The users of the fixtures are typically the best parties to know what is required, but these folks often don’t have the expertise to design them using standard CAD tools.

CAD expertise is at a premium, and often far away from the factory floor in some companies.

That’s where Fixture Designer comes in. It’s a very straightforward tool that allows basically anyone to very quickly design a fixture for a set of parts and produce a 3D model. This can then be immediately 3D printed and put into use on the line.

Should there be an issue requiring an adjustment to the fixture, that’s an easy fix: just open up Fixture Designer again and do the tweaks. This allows quick iteration of fixture design right at the point of use. That should provide for the most excellent fixture designs in any factory situation.

trinckle has provided a quick video overview of how Fixture Designer works:

As you can see, it’s very straightforward to use, and almost anyone could use it to generate competent fixtures almost immediately.

I see this as one more way to break down the barriers to leveraging 3D printing. While many 3D printer manufacturers tout the use of the technology for making fixtures, there are still challenges in doing so simply because of the software design barrier. Here, trinckle makes it easy to produce fixtures, and that should definitely increase efficiency, quality and also increase the level of 3D printing.

Via trinckle