Charles Goulding Jr. examines how 3D printing fits into critical plans to reduce carbon emissions in the transportation sector.

Back to Paris

As part of his climate plan, President-elect Biden has pledged to recommit the United States to the Paris Climate Agreement. If the United States is to meet its goals pursuant to that Agreement, it must look heavily at the transportation sector.

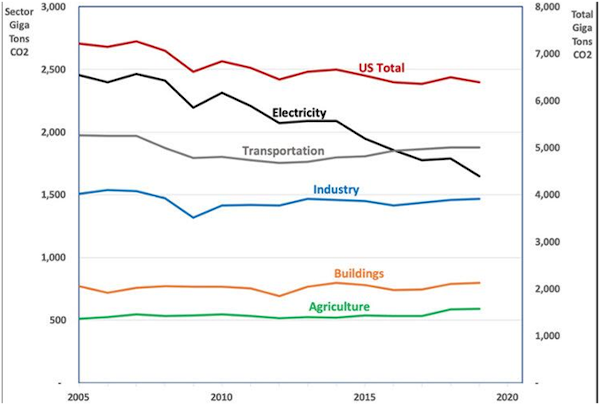

Transportation includes emissions from cars, trucks, busses, planes, trains, and ships. All told, the sector amounts to 28% of total emissions, making it more responsible for climate change than any other.

Not only is the sector the biggest carbon contributor, but its recent dip in emissions owes only to the pandemic, not to meaningful structural change:

3D printing can and must play a role in decarbonizing transportation. From making vehicles lighter to supply chain enhancements, 3D printing can transform much of how the sector operates.

Vehicle Weight

Lighter vehicles require less fuel to operate. GE has already taken advantage of this concept, printing aircraft parts that are 25% lighter than their traditionally manufactured counterparts. For example, new GE planes contain 19 3D printed fuel nozzles in their jet engines, each significantly lighter than its earlier iteration.

A recent Volvo trucking experiment with fuel engines yielded similar results: 3D printed components came in 25% lighter, resulting in a weight decrease from 1,157 pounds to 892.

According to the EPA, for every 100 pounds taken out of the vehicle, fuel economy is increased by 1-2 percent. Therefore, for the Volvo truck above, a decrease of over 250 pounds would make those trucks 5% more efficient, all else equal. That may not seem like much, but for a sector that leads the world in emissions, a five point drop amounts to an immense decrease in atmospheric carbon.

The U.S. moves a substantial amount of freight by truck. Trains use three to four times less fuel than trucks. The rail industry is utilizing 3D printing to make trains much more resilient and efficient.

Maritime shipping presents yet another area of potential CO2 reduction. Shipping accounts for over 2% of global emissions, largely from long voyages powered by diesel engines. On top of supply chain efficiencies for spare parts, 3D printing can also help with diesel engines of the future — engines that emit far less pollution. Cummins, for example, has spearheaded parts production for next-gen diesel — as well as electric. These engines will be critical in preventing maritime from quintupling maritime emissions by 2050.

Electric Vehicles

If transportation is to truly transform itself, however, electric vehicles must dominate the road. That means major opportunities for 3D printing, which has recently made remarkable advancements within the field.

One especially exciting example is a fully 3D printed vehicle from Italy’s X-EV. At 57 components, the “YoYo” is far lighter than conventional vehicles. Though small, the firm claims even a rugby player can sit comfortably inside.

Another exciting development in 3D printing for electric vehicles involves cars with integrated solar panels. Parts include heat-resistant battery fixtures for Futuro Solare’s aesthetically remarkable Archimede, pictured below:

3D printed cars and car parts like these can contribute to profound changes to global life.

According to Carbon Brief, “In the UK in 2019, the lifetime emissions per kilometre of driving a Nissan Leaf EV were about three times lower than for the average conventional car, even before accounting for the falling carbon intensity of electricity generation during the car’s lifetime.”

If “conventional” electric cars can be that much more efficient, lightweight 3D printed electric cars could cut into transportation emissions even more.

Supply Chains

Not all transportation sector decarbonization must come from vehicles themselves. That’s because when a supply chain becomes more consolidated, fewer inputs must travel from point to point. 3D printing has a unique ability to reduce the amount of such movement.

For starters, manufacturers now have the ability to produce component parts themselves rather than ship in inputs from suppliers.

According to Ford, “In the last few decades, Ford has printed well over 500,000 parts and saved billions of dollars and millions of hours of work. Where it would have taken 4-5 months and cost $500,000 to produce a prototype with traditional methods, a 3D printed part can be produced in a matter of days or hours at a cost of a few thousand dollars.”

The process depicted above has profound implications for supply chains. Rather than source prototypes and other parts from outside suppliers, a company like Ford can make its own.

Increasingly, 3D printing helps firms do just that, including when a supplier can send a digital design file rather than send the prototypes themselves. In some cases, producers can achieve total integration of all design, production, and distribution, virtually eliminating travel along supply chains.

Manufacturing speed also has important implications for supply chain efficiency. When products can be made more quickly, a producer can work within an on-demand model that drastically reduces inventory. Less inventory means less need for component parts, as well as less distribution of finished products. All such supply chain enhancements reduce the carbon footprint of that chain.

If a fifth of all carbon emissions come from supply chains, whether tallied in transportation or another, emissions reductions deriving from 3D printing R&D and implementation will be critical.

The Research & Development Tax Credit

3DP firms innovating in technologies that touch on desalination can avail themselves of the federal R&D tax credit to help subsidize their research efforts.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include U.S. employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, U.S. contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum Tax for companies with revenue below $50MM and for the first time, pre-profitable and pre-revenue startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Conclusion

The $2 trillion Biden climate plan includes billions in transportation sector investment. The goals of the plan include zero emissions for 100% car sales by 2035 and by 2040 for trucks. Given these targets, it’s clear that a great deal of federal support will accompany private firms in innovating next-generation electric vehicles, new infrastructure, and supply chain enhancements. It’s clear, further, that 3D printing will play an important role in these crucial objectives.