Charles R. Goulding and Preeti Sulibhavi have some thoughts about what trends we might see in the world of 3D printing in 2024.

Happy 2024. It’s the start of a new year and time for us to make resolutions with the best of intentions that we promise to keep. In this new year, we have several predictions related to 3D printing industry trends that we would like to share.

The Inflation Reduction Act (IRA)

This is transformation legislation and is encouraging substantial alternative energy investments including solar and geothermal. For energy efficiency, it is driving large investments in lighting and HVAC.

India’s Strong Economy

The rate of economic growth and foreign investment in India is fueling its economy. India is the world’s fifth-largest economy by nominal GDP and third largest by purchasing power parity (PPP).

India is set to overtake Japan and Germany to become the world’s third-largest economy, according to S&P Global and Morgan Stanley. S&P’s forecast is based on the projection that India’s annual nominal gross domestic product growth will average 6.3% through 2030.

“India has the conditions in place for an economic boom fueled by offshoring, investment in manufacturing, the energy transition, and the country’s advanced digital infrastructure,” Morgan Stanley analysts led by Ridham Desai and Girish Acchipalia wrote in the report. “These drivers will make [India] the world’s third-largest economy and stock market before the end of the decade.”

We have covered India’s economic growth rate on Fabbaloo. At that time the prediction that it could be the world’s third largest economy by the end of the decade had not been made.

We see India continuing its rise to power in the Indo-Pacific region.

Israel’s War with Hamas

- Palestine’s 100,000 damaged buildings and infrastructure

We hope that the War comes to a conclusion in 2024. The Israel-Hamas War has caused much of Gaza’s buildings and infrastructure to be damaged if not completely destroyed. We see this as an opportunity for the 3D printing industry, particularly with green cement materials, to help rebuild.

The future need to rebuild homes, roads, bridges and hospitals will be formidable.

- Replenishing the defense supply chain

Stratasys is a 3D printing leader, headquartered in Israel, which can pioneer the effort. Stratasys has always been aware of the Israeli military risk profile and has the Israeli military as a major customer and we suspect this relationship may expand during and after the war with the need to replace and repair military equipment including rockets, drones, tanks and munitions.

Replenishing the Military Supply Chain

We all saw how supply chains can crumble during the Coronavirus pandemic. This is especially problematic for the US Department of Defense (DoD). The need to modernize our weapons systems and equipment is not breaking news. But the urgency to strengthen military supply chains has never been greater. The new year is a year in which we see more 3D printing applications in our armed forces. Whether it is to repair and maintain equipment in the field, or to create high-quality ammunition for battle, 3D printing technology will increasingly become an integral piece of military-grade equipment.

Embedded Electronics as a High Growth Area

We expect to see an increased use of 3D printing for embedded electronics and Nano Dimension is the leading company we follow.

By textbook definition, Embedded Electronics can be defined as a system that “Integrates Hardware circuitry with software programming techniques to provide real-time solutions.”

Embedded systems are commonly found in consumer, industrial, automotive, home appliances, medical, telecommunication, commercial, aerospace and military/defense applications.

Telecommunications systems employ numerous embedded systems from telephone switches for the network to cell phones for the end user.

From age-old pocket calculators to advanced automobile and security devices, the applications of embedded systems continue to show strong progress and will do so in the upcoming year.

MedTech and Pharma will Advance Even Further

We see MedTech and pharma as the new age of manufacturing in the US. Whether it is telemedicine, bioprinting, the integration of artificial intelligence (AI), cyber-securing healthcare data, creating customized pharmaceuticals, or creating comfortable yet fashionable wearables, the 3D printing industry will have even further reach in the coming year.

With brick-and-mortar pharmacies being less relevant and being replaced by online, digital pharmacies that customize and deliver patient medications in prescribed dosage amounts, retail pharmacies that have not shuttered will eventually be point-of-care facilities for minor healthcare visits. This is an opportunity for integrating 3D printers at centralized locations to help with patients’ needs (i.e., adjusting a patient’s “specaids”).

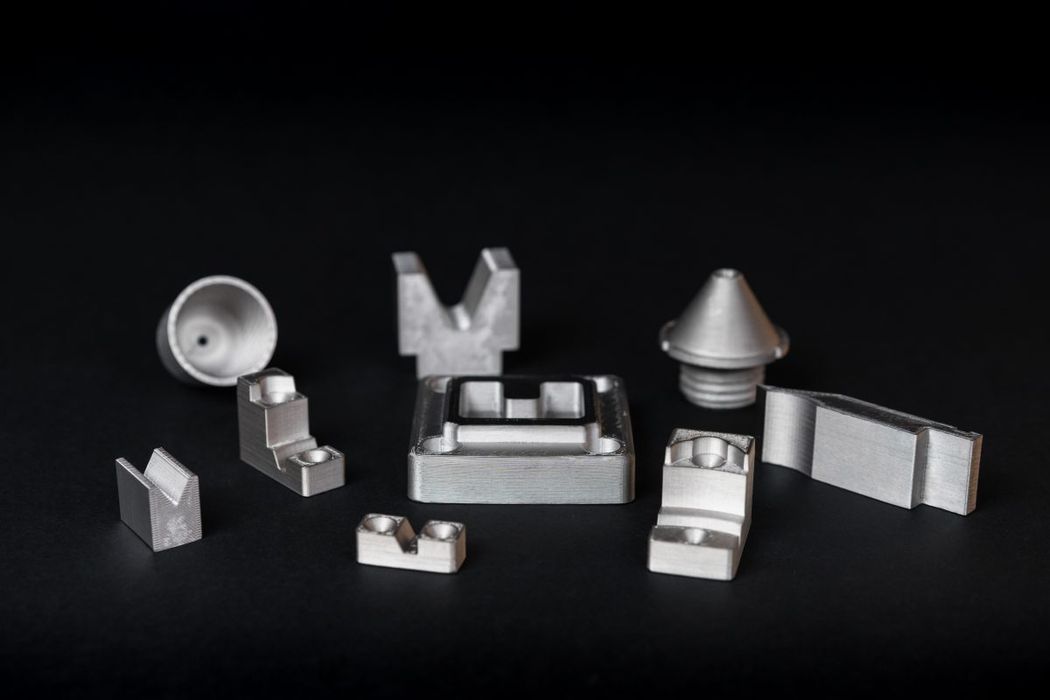

Metal Product Offerings will Respond Positively

In order for 3D printers to be integrated into the defense, automotive and construction industries, metal 3D printing must advance. We see the industry going in this direction in 2024. Particularly, Markforged has created an Atomic Diffusion Additive Manufacturing (ADAM) process for printing metal, unlocking a new era of metal parts production. Revolutionary ADAM technology makes it safer and easier to print metal parts compared to previous metal 3DP methods.

ADAM is an end-to-end process that starts with metal powder and captures it in a plastic binder, which makes it nonflammable, safe to breathe and easy to handle. The part creation process builds on existing carbon fiber reinforced extrusion technology – where micro strands of carbon fiber are bound in plastic. It then forms it into the part shape one layer at a time. After printing you sinter the part in a furnace, burning off the binder and solidifying the powder into the final fully dense metal part. Thermally sintering parts is well-established in the Metal Injection Molding (MIM) industry to create end-use parts for medical, aerospace, and consumer applications. So, this appears to be a logical approach. The applications to various verticals are limitless.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

As tradition goes, we are putting the above applications for 3D printing on our New Year’s resolution list of things to look out for in 2024. The trends listed above are our best guess for the future and we can’t wait to see how the 3D printing industry helps these markets innovate further in the coming year.