Titan Robotics announced a new 3D printer, the massive Atlas-HS.

Colorado-based Titan Robotics has been developing large-format 3D printers for quite a few years. We first saw them at CES way back in 2015, where they were among the first companies to market 3D printers of such a large build volume. Their machines use servo motors to ensure high quality 3D prints for each job.

Since then they’ve continued to improve the process of large-format 3D printing for industry with a number of useful features. One of the most interesting has been their use of pellet materials. Most other large-format 3D printers make use of filaments, and that can be quite expensive when producing the very large parts in machines the size of the Atlas. Their pellet extruder allows use of material that can be 10X less expensive.

Now they’ve taken an intriguing step forward with the Atlas-HS, which includes a hybrid toolhead system.

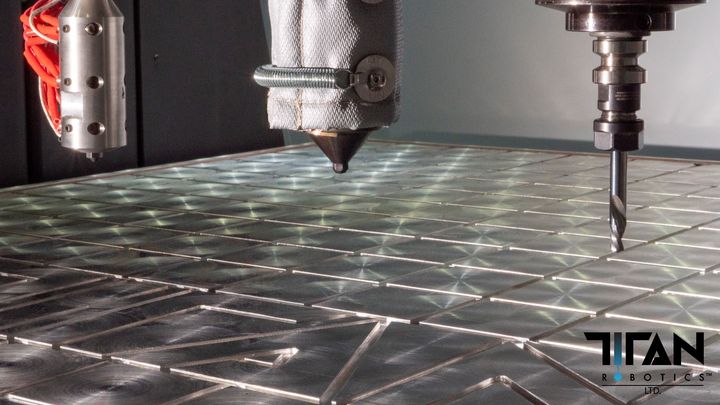

The Atlas-HS includes a pellet extruder as do the prior models, but it also includes a CNC milling head. Thus this machine can perform both additive and subtractive manufacturing in the same build chamber.

Why not just buy a separate CNC machine? It’s all about optimizing the build process.

While very large objects can be quickly 3D printed on the Atlas series, the cost of rapid printing is resolution. This is the case in almost all large-format 3D printers, where rough surface textures are not quite so visible on bigger items.

However, there are many cases where surface accuracy is required, in particular for parts that must fit together. This usually led to a two-step process where the part was first 3D printed, and then taken to a separate CNC mill to refine the surface to the required tolerances.

That workflow will now be simplified with the Atlas-HS, which includes the CNC process right in the same build chamber. There’s a hint in the new machine’s name: “HS” stands for “hybrid system”.

The new milling system is mounted on the same gantry, and inherits three axes of motion. This suggests that the usual process for the Atlas-HS will be to 3D print a layer or three, then engage the milling head to smooth the edges of those freshly printed layers. The printing resumes and eventually the object completes with a perfectly smoothed surface that perfectly matches the desired geometry.

The Atlas-HS is available in several build volumes upon order, ranging from 1067 x 1067 x 1118 mm, all the way up to a monstrous 1270 x 1270 x 1829 mm. For those keeping track, that’s a build volume of almost 3,000L!

Like it’s predecessors, the Atlas-HS’s pellet extruder and heated build chamber allow use of a wide variety of industrial materials, including PEI-CF, PEKK-GF, PP, PA, PC-GF and many others.

Readers requiring large-format 3D prints with high-tolerance surfaces might consider looking at the new Atlas-HS from Titan Robotics.

Via Titan Robotics