A video has emerged that shows what is likely the smallest 3D printer ever made.

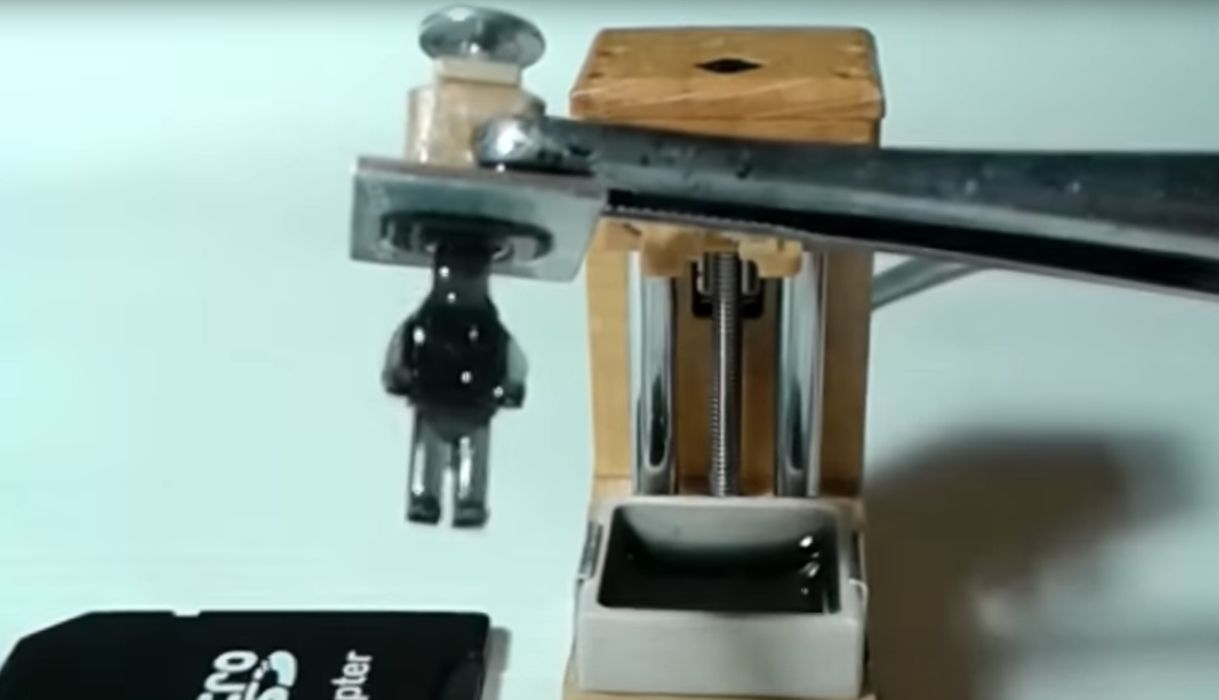

The video, produced by the almost anonymous My N Mi, shows the operation of a very, very tiny MSLA 3D printer. MSLA is a resin process where light from an LCD panel selectively cures layers of resin to gradually build an object layer by layer.

My N Mi bills the unnamed device as the “World’s Smallest 3D Printer”, and I don’t doubt it. There have been 3D prints of “3D printer sculptures” that are smaller, but this thing actually works. Something the size of an AirPods case can actually produce 3D prints!

There are specialized micro printers that have similarly small build volumes for unusual applications, but the machines that do so are vastly larger than this device.

In the ten minute video you will see the printer in action, producing an obviously small figurine from black resin.

The specifications:

- Machine dimensions: 18 x 31 x 41 mm

- Machine weight: 17g

- X-Y resolution: 0.135mm

- Layer height: 0.300mm to as low as 0.005mm

- Build volume: 11 x 11 x 17 mm

Operation of this device is a bit unusual, because human fingers are far to large to be used in the normal manner. The resin tank, print plate and other components are so small they require special tools.

To load the resin tank, a syringe is used to carefully place a few drops of resin into the tank. To remove the print plate, tweezers are used to grasp the plate and lift it off the printer.

Missing from the printer are a couple of standard elements. There’s no UV cover, but for the length of time these prints would take, there’s little point to include one. There’s also no control panel, and that’s because any readable panel would be much larger than the entire printer!

It’s not shown in the video, but I suspect the device does not include a controller and is being run from a PC off-screen. This would greatly simplify the design as there isn’t room for any of the typical controller boards.

This project, while totally impractical, demonstrates one point quite clearly: MSLA 3D printers are extraordinarily simple. They require a one-motor print plate motion system, a resin tank, a light engine (usually off the shelf), and some software.

Most desktop resin 3D printers are made in the same way, it’s just that they are a lot bigger than this tiny 3D printer. This is one reason the price of that style of 3D printer has been continually dropping: there’s just not that much to them.

Via YouTube