Thought 3D has published a very interesting study on drying nylon filament.

Nylon, also known as PA, is a popular 3D print material. It can produce highly durable parts that have the ability to flex. This makes it ideal for all kinds of applications.

Unfortunately, nylon is a devil to print. It warps almost uncontrollably, and usually requires extra-special hold-down actions.

But far worse is its ability to absorb moisture from the air. Exposure to ambient air for only a day or two can literally ruin a spool of nylon filament. The absorbed moisture boils out during printing and forms bubbles, which destroy the material strength and mess up the visual appearance.

The bottom line with nylon is that you shouldn’t be printing it unless it just now came out of the filament dryer.

That’s where Thought 3D has been working. In the past couple of years they’ve developed and released an accessory called the “Drywise”. It’s a filament dryer, but one with a difference: it operates in real time.

Instead of baking a spool for a day, the Drywise dehumidifies filament as it passes into the printer. This means you can start printing at any time by simply turning on the Drywise.

To promote the Drywise, Thought 3D has published a new paper entitled, “Effect of Humidity and Drying on the Strength of 3D Printed Nylon Parts”.

One of the key points I noticed in the report was this:

“However, the process of controlling moisture in the filament is not always clear to the user. In fact, the user has no way of gauging the amount of moisture in newly opened filament spools, which have a very high chance of containing excess moisture. Nylon filaments also tend to rapidly absorb moisture if they are not stored in a dry box, leading to sub-par prints within hours of exposure to moderate to high humidity.”

This is quite true: when you crack open a spool, how do you really know whether it’s actually dry? And exactly how dry is it?

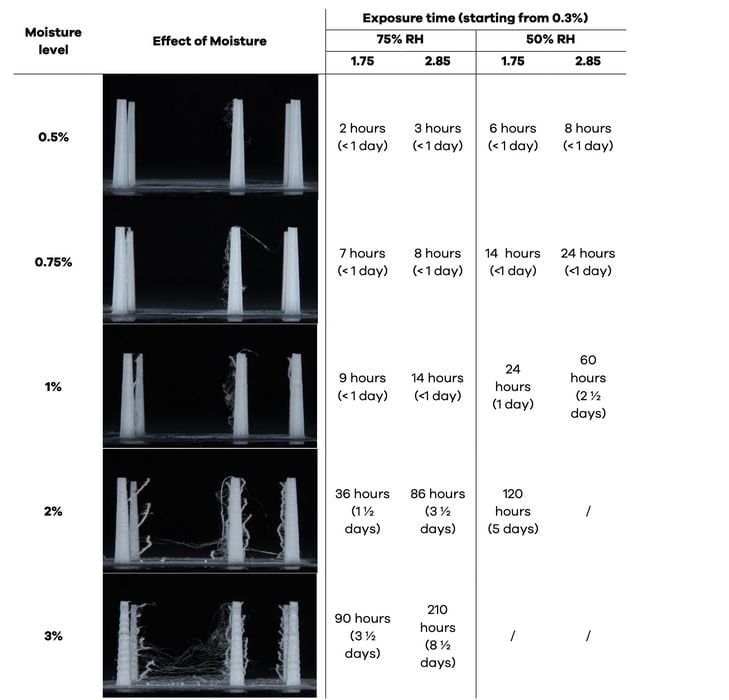

Most importantly, the report produced this chart that examines the effect of exposure at varying levels of ambient humidity for different durations.

As you can see, there’s not too much effect for an exposure of a couple of hours, even at high levels of humidity. The problems begin when exposure is more than a few hours.

According to the chart, you’ll experience stringing with less than a day’s exposure. After three days, it seems pointless to even attempt a nylon 3D print at any level of humidity.

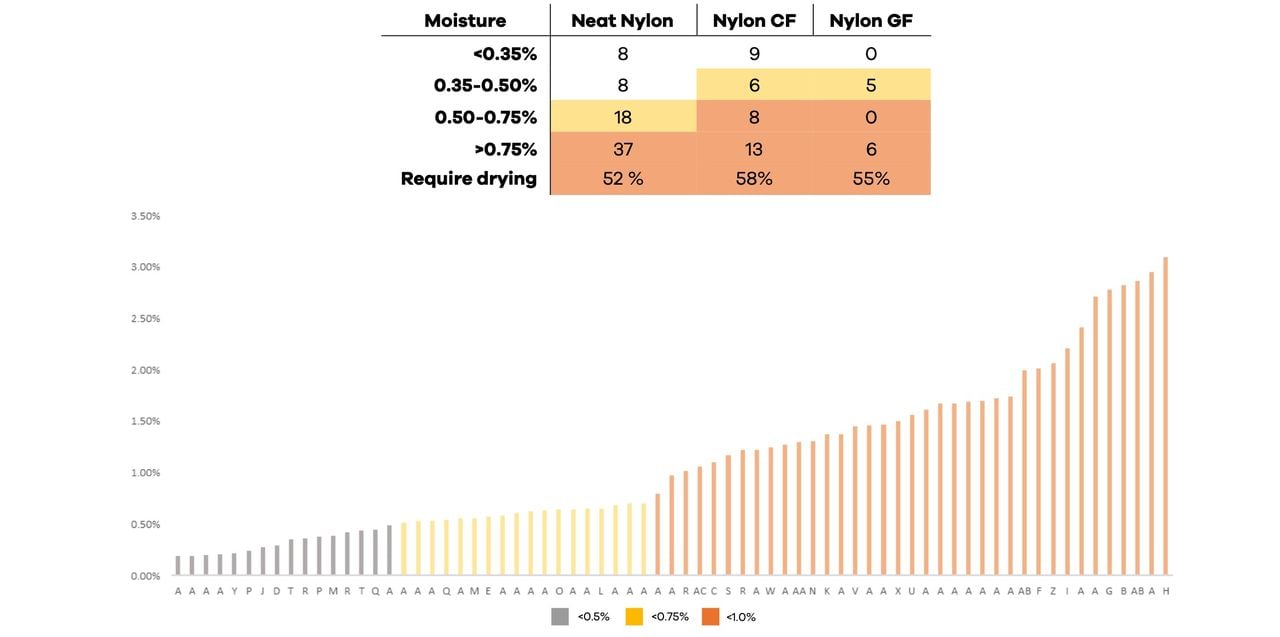

They also tested random fresh spools of nylon and found that a substantial proportion, 37%, required drying even right out of the package. This suggests that anyone 3D printing nylon should put the spool into a dryer immediately when opened and avoid printing until it’s truly dry.

The study also tested filament manufacturer’s drying recommendations and found that in some cases they were inadequate, as extreme humidity could push moisture levels higher than the recommendations could manage. They also found that 2.85mm filament takes far longer to dry than 1.75mm, which isn’t surprising — but I am not certain if all recommendations account for this.

The report then proceeds to examine the strength of parts produced in varying conditions, and as you might suspect, drying should be mandatory in all cases. Their Drywise unit performs well, and the difference is shown in the image at top.

In all, this is quite an interesting report and by far the most detailed I’ve seen on the topic of drying nylon.

Via Drywise

https://drywise.co/