Thought 3D has been expanding the capabilities of their Drywise system.

The Malta-based company is most well-known for their line of Magigoo print plate adhesion solutions, but in recent times they’ve branched out with another accessory for 3D printing: the Drywise in-line filament storage system.

The system is designed to remove the moisture from filaments, since absorbed moisture boils out during the hot FFF 3D print process, usually ruining the print’s quality. This effect is especially present on certain engineering materials, such as nylon, which rapidly absorb humidity from the air.

There are plenty of drying solutions, but most of them are simply a “dry box”: a sealed container with either desiccant or a heater to slowly purge moisture from the filament spools within.

The Drywise is not another “dry box” which is so often seen in the industry these days. Instead it’s an “in line” solution.

Instead of drying the filament during a lengthy process ahead of time, the Drywise dries the filament during printing. As the filament is drawn by the printer from the Drywise, it undergoes a drying process. It’s analogous to those instant hot water heaters seen in modern homes, instead of the old water tanks.

The in line approach is better because it’s a real time solution. Imagine the scenario where you want to 3D print an object in a particular engineering material, but at the last minute realize you forgot to put the spool in the dry box the day previous. Oops! With an in line solution it doesn’t matter: just install the spool and print.

In a recent discussion with the folks from Thought 3D, I learned that they’ve been busy certifying a lot more materials for the Drywise. This identifies the drying parameters for the Drywise to use with the material.

They’ve now added capability for many more 2.85mm filaments, which should assist 3D printers operating Ultimaker or LulzBot equipment, which often use that filament format.

One of the more interesting materials they’ve enabled is Markforged’s Onyx.

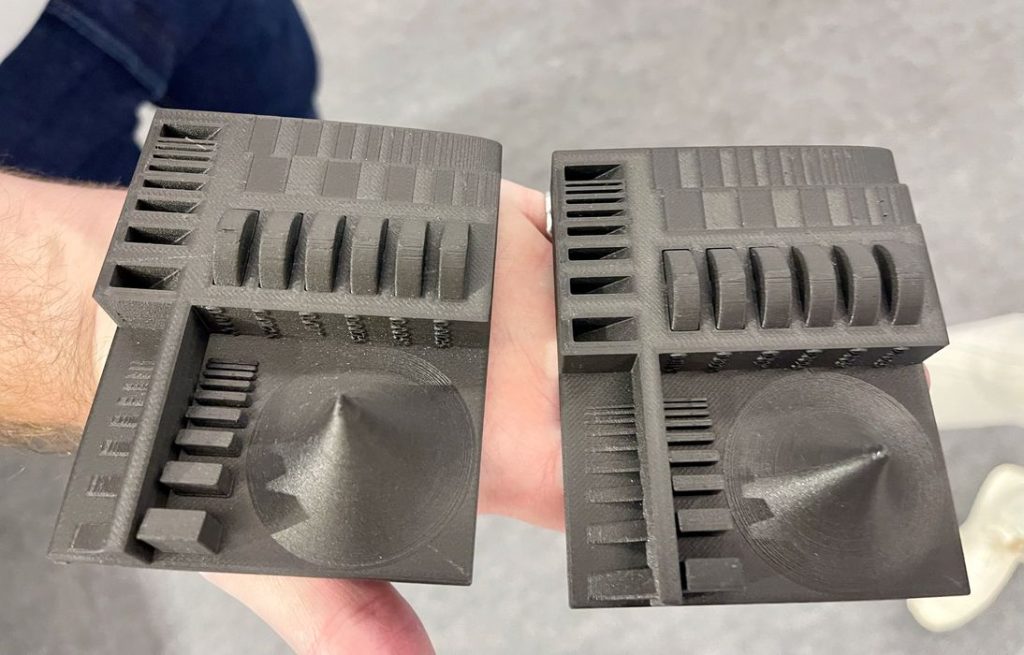

Onyx is a composite of nylon and chopped carbon fiber (which gives it its dark appearance). It’s an incredibly strong material, and one used in that company’s systems to produce production-ready parts.

But that happens only if the Onyx filament is sufficiently dry. Here you see a comparison of Markforged Onyx 3D prints made with the Drywise and without.

For those producing production parts with these exotic materials, drying filament is a necessity. The Drywise offers a unique way to get the moisture out and ensure the highest quality prints.

Via Thought 3D