Thies is a company providing equipment for dyeing 3D prints, but with a big difference.

When I first encountered Thies at Formnext, I initially believed them to be one of several startup companies focusing on dyeing 3D prints.

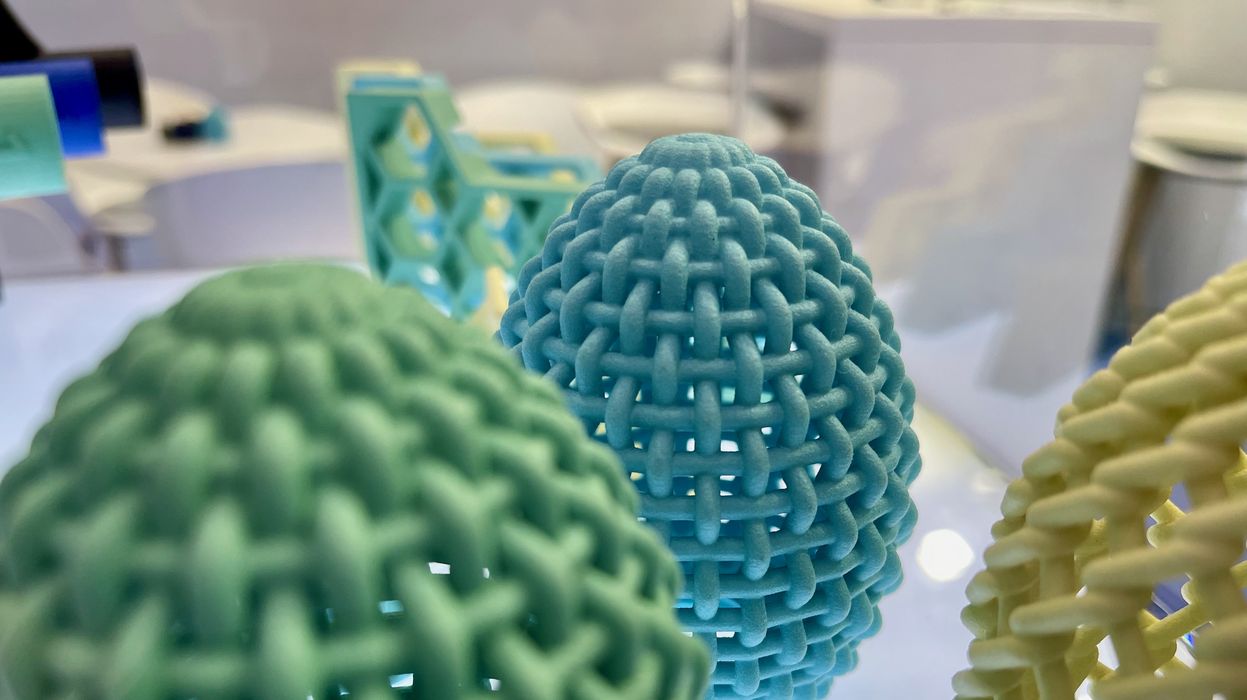

Dyeing is commonly done with white SLS 3D prints. White nylon is an excellent medium for accepting colors, and SLS systems can mass produce parts of this type. Many production lines 3D print consumer parts that are then dyed to meet color requirements.

The simplest form of dyeing is to toss fresh prints in a pail of water that has some dye mixed in. However, while that does color the print, it is an entirely unpredictable process that is totally unacceptable for production use: all parts must have exactly the same color, texture and surface finish.

To address that need several new companies have popped up with dyeing solutions for 3D printed parts, all with the goal of consistent and brilliant colors.

I thought Thies was one of them, but I was wrong.

In fact, Thies is a 130-year old company. Their business is to make pressure vessels for industrial fabric dyeing. They’ve been dyeing textiles for literally a century or more, and because of that they know everything possible about fabric dyeing.

But so what? Fabric is fabric, and 3D prints are 3D prints.

Then it hit me: many materials used to make fabric are in fact THE SAME AS 3D PRINT MATERIAL.

This meant that Thies knows a great deal about dyeing 3D prints, even before they got into that business.

They now have entered the 3D print market with their own dyeing solutions that leverage their tremendous knowledge of the topic. For example, their equipment uses heat in ways that other systems may not, and as a result their equipment uses less dye than other systems. They described it as a kind of “sous vide” approach for dyeing.

They are able to max out the diffusion rate, somehow.

In addition, the dye solution can be cooled and then reused, adding to the economy of the system.

Here we see another one of their several innovations. It’s a small carrier into which multiple dyeing mixes can be placed, and run through the dyeing sequence.

There are at least two ways to use this. First, one could place multiple batch variations for testing. This could very quickly determine the correct mix in only a single dyeing run. Another use would be to dye parts in separate and different colors in the same job.

But that’s not all: Thies representatives explained that color is not the only process that can be done with their machines. Through their extensive fabric experience, they know it is possible to add properties to the parts beyond just color.

For example, they could add a solution to provide UV protection to a part. Another solution might add anti-static features to a part. You get the idea: there are dozens of possibilities here.

Dyeing is not just about color.

Via Thies