Charles R. Goulding and Preeti Sulibhavi believe Denmark to be a pioneer in extensive use of 3D printing for sustainable energy generation.

Denmark, a large peninsula jutting off Germany is considered a Nordic constituent country in Northern Europe while being labeled as the southernmost Scandinavian country, lying just southwest of Sweden. It has the best of both worlds, a unified kingdom as well as a thriving metropolis.

Maybe because of its geographic attributes it has become a leader in the offshore wind turbine industry. Ultimately, anyone familiar with the wind turbine industry and the series of developments and innovations associated with offshore wind will inevitably come across the name Henrik Stiesdal.

Often mysticized and associated with Vikings more than wind turbines, Denmark is a wind power pioneer, thanks in part to Stiesdal. In a May 13, 2023, New York Times (NYT) article, Stiesdal was featured as a true innovator and a changemaker in the wind power industry. The article explained that his passion for clean energy began in his early twenties when he build a very basic wind turbine to power his parents’ farm.

Offshore wind energy was originally developed on the basis of the Danish success with onshore wind power. Denmark was the first country in the world to install an offshore wind farm. Denmark has been setting clean energy records for a few years now because of its strategic use of wind power. In 2019 Denmark sourced almost half of its electricity consumption from wind power.

We have previously covered the expansion of 3D printing in the wind turbine industry. From Ørsted’s contributions to the wind industry to the 3D printing research and development taking place in Denmark, Denmark and 3D printing are symbiotic elements.

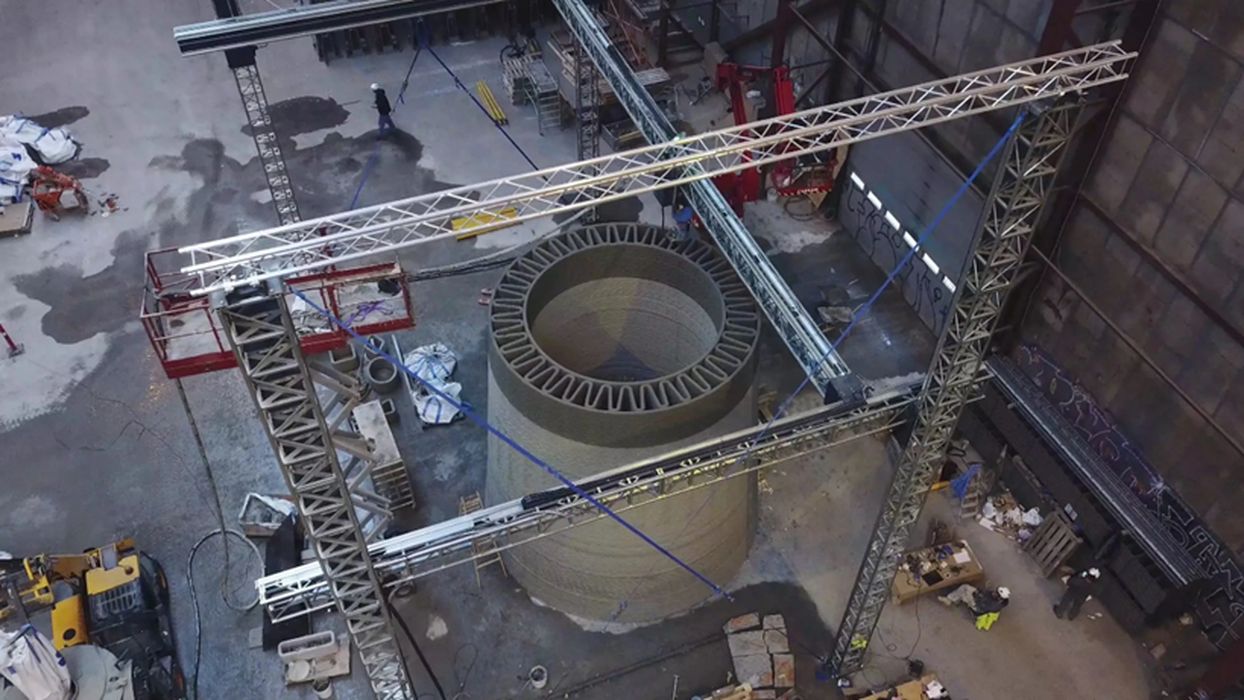

Not only is concrete taking the 3D printing industry by storm but at GE it is being applied to the fabrication of wind turbines. Wind turbine bases can be 3D printed using concrete as the material. The 3D printed bases will help to harness more wind energy by reaching heights up to 200 meters.

3D printers will enable engineers to construct bases with variable heights on site and on demand. Not only will this increase renewable energy production, but it will decrease the Levelized Cost of Energy (LCOE) and lower construction costs. GE, COBOD and LafargeHolcim intend on bringing this technology to scale in the near future.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Gone With the Wind…

Reducing the cost of generating energy while creating sustainable forms of energy is the goal for many countries. While it may not be surprising that Denmark, being a peninsula surrounded mostly by water, is leading the world in wind power, the resourcefulness of the Danish people and Stiesdal in particular, is commendable and remarkable.