New research has shown a way to 3D print wooden objects that automatically unfold.

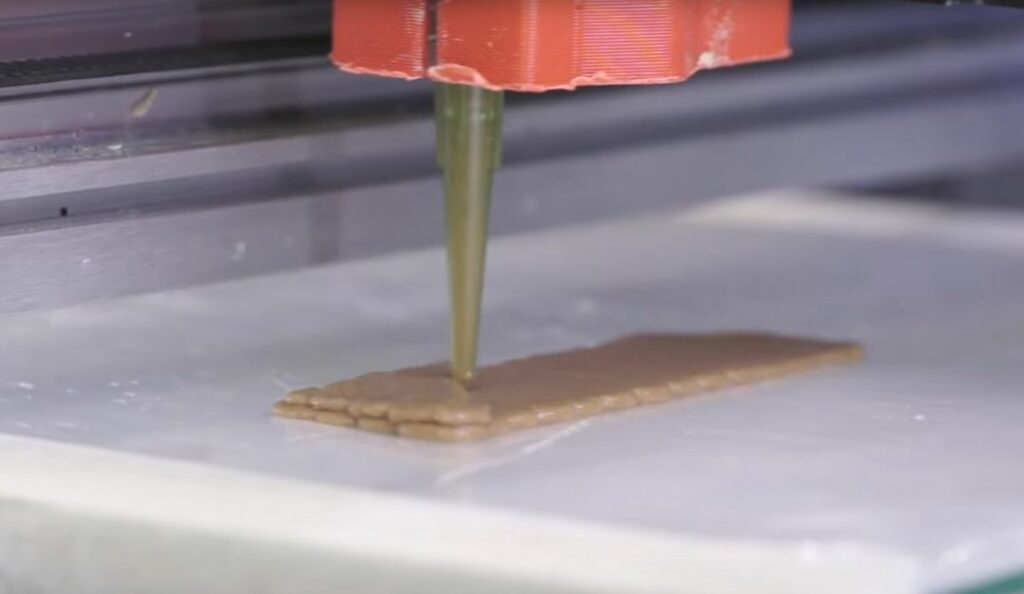

The American Chemical Society published a video showing an unusual experiment involving 3D printed wood fiber.

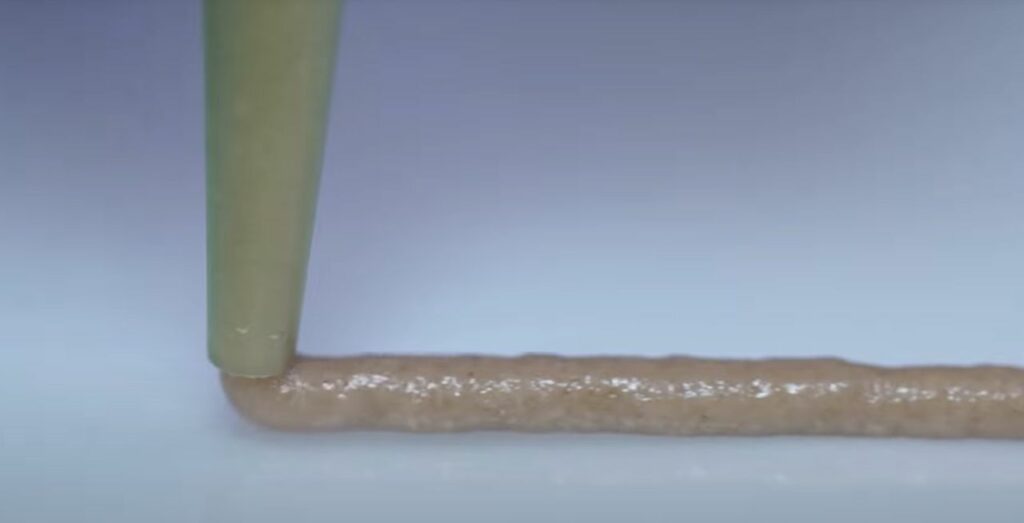

The extruded material was a mix of “wood flour”, which is a normal waste product from conventional wood processing, and a polymer mix. This material was set up in a 3D printer equipped with a syringe-powered deposition nozzle, similar to what you’d see used for ceramic or food 3D printing.

This wet mixture is extruded, but then dries out as the water in the mix evaporates. This is where the interesting part occurs.

As the material dries, it warps.

The researchers found that they could control the degree and direction of warping through speed adjustments on the deposition sweeps. Apparently, if the deposition motion is swift, then the wood fibers in the extrusion line are more aligned. If extruding slowly, the wood fibers are more randomly oriented.

Random wood fiber arrangement means uniform warping in all directions, but aligned fibers generates a predictable warp!

With this principle discovered, the researchers were able to generate unusual toolpaths that took advantage of this effect to create printed objects that would warp in specific ways.

Here you can see a kind of “potato chip” structure that’s been created from a flat 3D print. At top you can see a structure that twists when dried.

While this seems simple, it may be possible to create more sophisticated designs that can unfold into useful structures and mechanisms. However, this will require complex toolpath analysis and 3D software development.

Where will this lead? Perhaps IKEA will use this principle to ultimately create wood furniture that assembles itself once you crack open the wrapper and let it dry out.

Another possibility is that this work might inspire similar work using polymers that warp when 3D printed. Today these materials are a curse on the technology, but maybe that warp effect could be leveraged in more useful ways.

Via YouTube