Charles R. Goulding and Preeti Sulibhavi look at a new project by the University of Warwick.

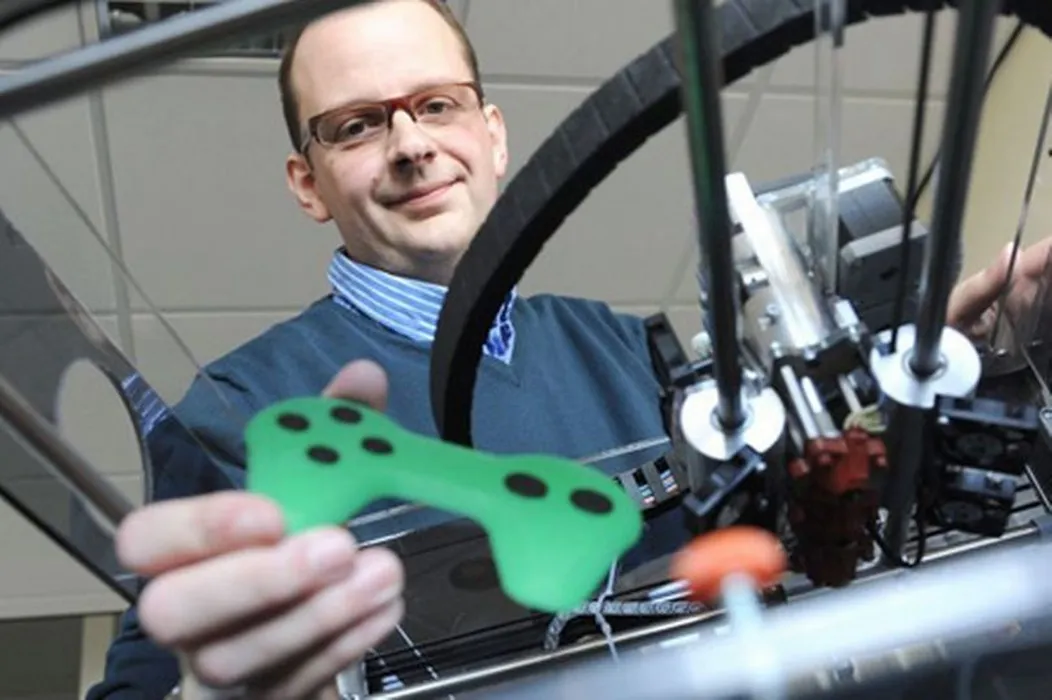

Known for its expansive coursework and technical expertise, the University of Warwick in the United Kingdom is no stranger to 3D printing. Far from that. In fact, Warwick Print is a new 3D printing service for staff and students that was developed to provide the Warwick community with a new technology that could revolutionize the way so many items are fabricated.

Iterate Design + Innovation, a company helping others to take ideas from concept to reality, has been awarded an Innovate UK grant worth £1 million (US$1.4M) to further develop its advanced 3D printing technology.

The start-up is based in Chepstow, South Wales and is made up of a team of design engineers. They aim to help their clients be first to market with their product, harnessing their ‘specialist knowledge’ of rapid product development.

With the £1m grant, Iterate will team with the University of Warwick, Printed Electronics Ltd, and C Enterprise – the makers of the CEL Robox – to embark on a project. Together, they will focus on combining electrically conductive inks with polymer-based materials, in a bid to replace the need for wires in electro-mechanical product assemblies.

In terms of biomedical advancements, there are many success stories coming out of the University of Warwick. One of the most applicable uses of 3D printing in the biomedical field is the use of robotic limbs for patients who require prostheses.

The IMPACT project, led by Iterate Design and Innovation Ltd, in collaboration with Warwick Manufacturing Group (WMG), University of Warwick, C Enterprise (UK) Ltd and Printed Electronics Ltd, was made possible thanks to a grant of nearly £900,000 from Innovate UK, with the aim of developing a 3D printing technology with the ability to print plastic products with integrated electrical circuitry, a capability which they have demonstrated in a bionic hand.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The University of Warwick is on the cutting edge of 3D printing technology. The world should take notice of how many applications 3D printing technology has enabled in today’s world.