Sunlu announced a new desktop 3D printer that could be among the fastest in its class.

Sunlu has been producing 3D printers for almost ten years, having successfully marketed many different models during that time. Now, the new “Terminator3” device is their latest model. It follows the standard design style of many inexpensive desktop 3D printers of this era, including:

- Open gantry design

- Solid base incorporating controller and power supply

- i3-style motion system

- Bowden-style extrusion system

- 0.4 mm brass nozzle using 1.75mm filament

- Shipped as a kit with simple three-step assembly

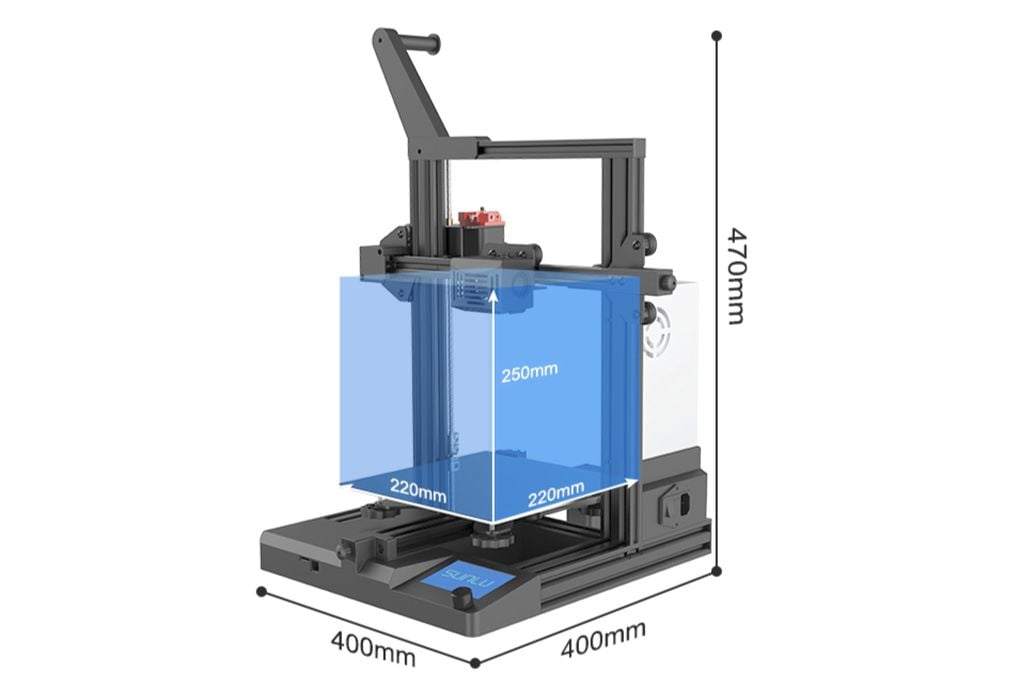

- Build volume of 220 x 220 x 250 mm

- Rigid aluminum extrusion frame

What’s different about this device is that it includes some more sophisticated features found on more advanced models:

- Silent 3D printing through the use of advanced stepper motor drivers. SunLu said the device runs at only 45dB, very quiet

- Power failure detection and resume feature

- Strong, all-metal dual-gear extruder for added grip on the filament

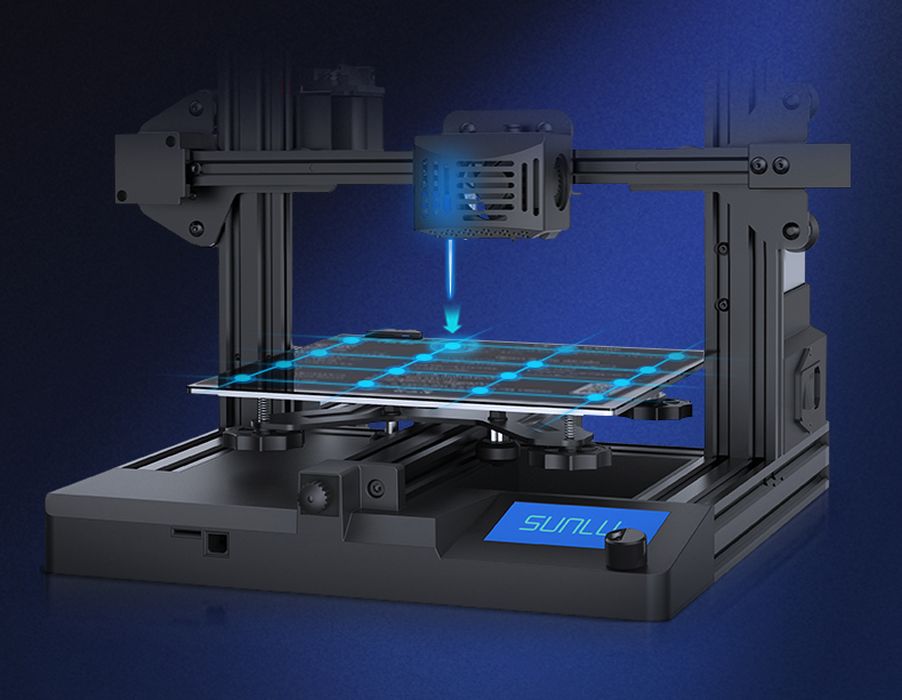

- Automated 16-point leveling and calibration routine

- Filament-out detection and automatic job pause

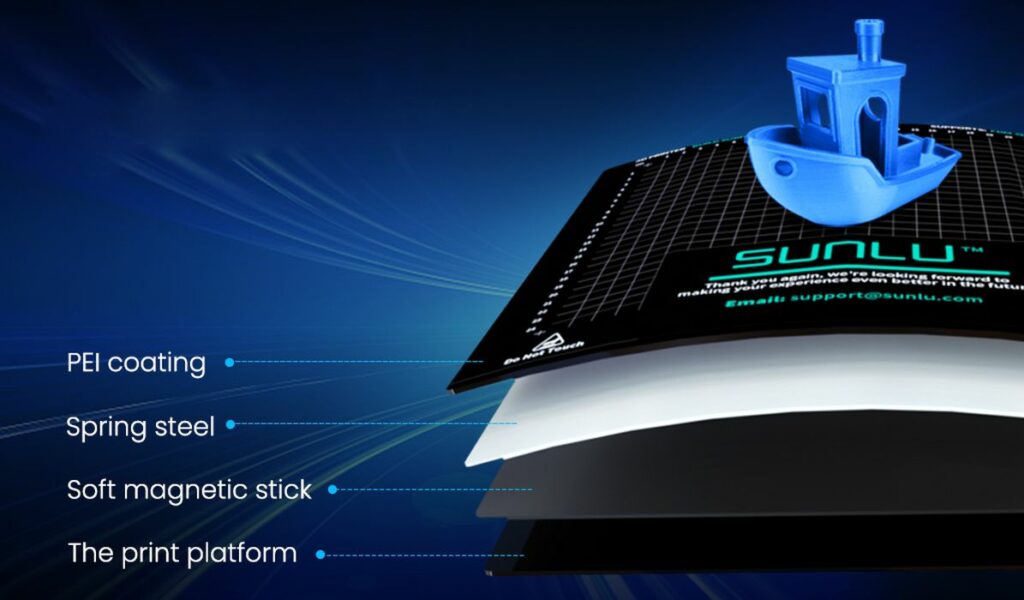

- Magnetically attached flexible build plate for easy print removal

- Belt adjustment knobs to avoid motion system slippage

That’s a pretty decent list of advanced features for a machine that sells for only US$279. However, there are two more features that are particularly interesting, and very rarely found on any machine.

The first is something Sunlu calls “Clog Detection”. They explain:

“Pauses printing and returns to standby when a clogged nozzle is detected. After unclogging the nozzle, continue the printing process to complete the model printing. Avoid failures caused by nozzle clogged.”

It’s not quite clear how this works, but I suspect Sunlu has some kind of sensor that determines if the filament is actually moving. When a clog in the nozzle occurs, that prevents forward motion of the filament. Thus, a filament motion sensor would be able to detect a clog.

The system then pauses and alerts the operator to fix the problem.

I’m quite interested in this feature, because clogs are something that happens quite frequently when using desktop FFF 3D printers, and it’s not always easy to notice until your print job has failed. This new clog detection system just might be able to allow resumption of a job even when a clog occurs. That’s a feature very few 3D printers have, and just thinking about it, all of them should have it.

The second and perhaps even more interesting feature is the print speed. Sunlu said the Exterminator3 can print at an astonishing rate of 250mm/s. This is five times faster than typical desktop 3D printers that run at a mere 50mm/s.

Theoretically the Terminator3 could complete jobs far quicker than other devices. However, it won’t be 5X as fast. That’s because the highest speed is only reached during long, straight movements, and most prints have a variety of toolpath movements required. Nevertheless, the print speeds should be quite good on this device.

What is a bit puzzling is how Sunlu achieves these speeds. It’s easy to set the print speed to whatever you want on any desktop 3D printer. But if you exceed the practical speed limit the print quality simply goes down rapidly. The question here is whether the Exterminator3 can produce good quality prints at such high speeds.

In order to run at high speeds, the following features should be present:

- Extremely rigid frame to avoid vibrations

- High speed controller to manage rapid motions

- Powerful extruder to keep up with the speed

It’s hard to say, but it would appear that the Terminator3 might have a rigid frame, but it could have some extra bars to keep the gantry from moving. We don’t know what controller Sunlu is using here, but powerful controller boards are increasingly common, so that’s probably not the issue. As for the extruder, they seem to have the correct design for higher speeds.

It could very well be that this machine does indeed perform properly at such high speeds. However, I’d like to see it running at 250mm/s and examine the output to be completely certain.

Via Sunlu