There’s an increasing amount of cooperation between 3D printer manufacturers and chemical companies.

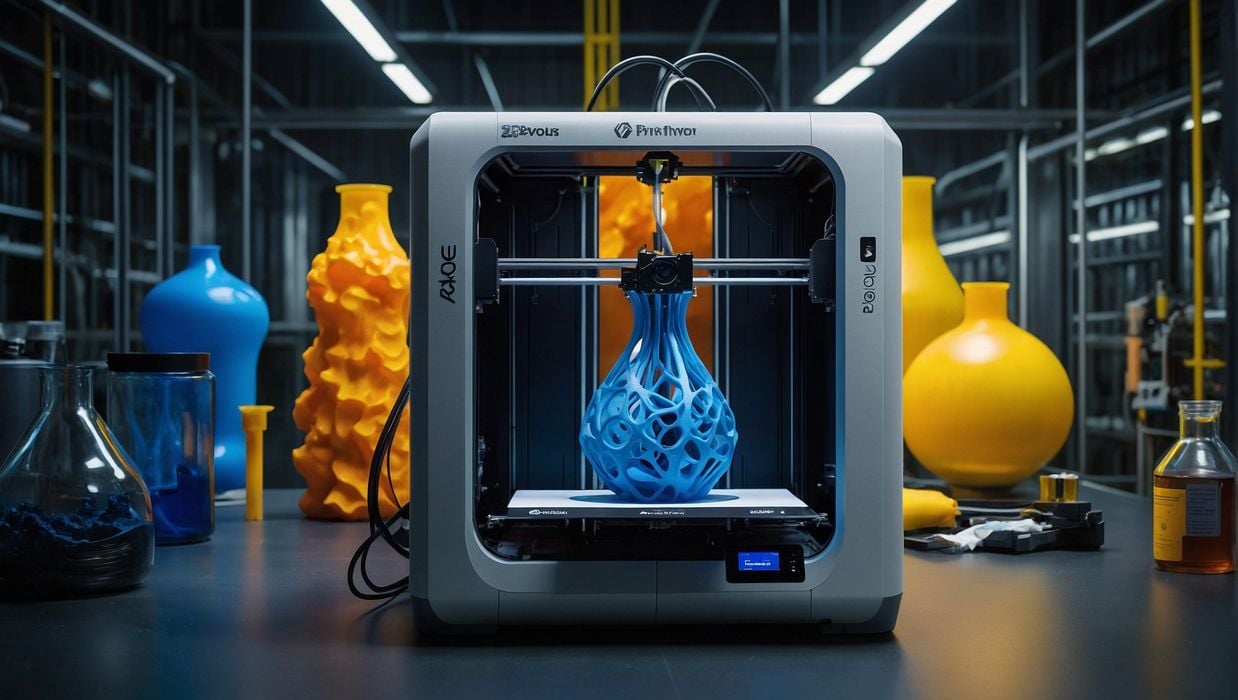

While there’s always been a big focus in the 3D printing industry on the 3D printers, they are only part of the equation. Another important part is the materials.

Materials have long been an issue in the world of 3D printing. Traditional manufacturing has had access to many thousands of different materials, each with unique engineering properties. The standard practice is for design engineers to sort through materials databases to find the best material for the application, the one that matches the required engineering properties. Those might be thermal resistance, impact strength, radio transmissivity, bio-compatibility or other factors. There’s almost always a material for the job.

Then those same engineers need a 3D printed part, perhaps due to unusual geometry that cannot be made with standard approaches. They very quickly find that the material availability is extremely constrained when 3D printing.

If you were to look at a complete list of available 3D print materials today, you’d find perhaps a few thousand materials. That might sound appealing, but in practice it’s not nearly as broad as it seems.

That’s because materials are very often certified for use only on specific equipment. In other words, if you purchased a specific 3D printer, you’d find a rather short list of potential materials that could be used for production purposes. The list could be only a dozen or so materials, maybe even less.

This puts equipment buyers in an odd position. Their application requirements require a specific material, so they might not start their equipment search by looking at machine capabilities, but instead by finding which machines can print that material.

For manufacturers this makes sales far more challenging. If their equipment doesn’t support that material, their equipment is not even considered. They’re off the shopping list immediately.

Because of this market pressure many 3D printer manufacturers have spent considerable effort to broaden the material types that can be used in their equipment. Since equipment manufacturers are not chemists, they frequently sign deals with chemical companies to make use of their ready-made materials.

After a certification process, the new materials can then be advertised as available, and this literally unlocks an entirely new set of clients and prospects that had been seeking that material. In other words, a 3D printer manufacturer can make their potential market bigger by simply adding a new material.

There’s a variant strategy that some undertake, however.

Instead of just adopting a chemical company’s existing products, they partner together to develop new and unique materials that were not in the chemical company’s portfolio. These would be specifically designed to work well in the manufacturer’s equipment, and almost certainly be available only to their customers. That approach not only gains market share, but also some lock-in due to the proprietary nature of the material.

This is why each week we see press releases from several companies that have made deals with chemical companies to produce and certify new materials.

We should expect to see this practice continue for a very long time.