Stratasys announced a massive US$20M contract to deliver 3D printers to the US Navy.

According to Stratasys:

“On August 23, 2021, the U.S. Navy issued Stratasys a $20 million contract to purchase up to 25 Stratasys F900 3D printers over the next five years, with delivery of the first eight expected before the end of 2021. In addition to the printers, the contract includes initial support and sustainment, materials, and development of initial training for the supplied systems.”

This is a big step for the US military. Director of U.S. Government Business Segment for Stratasys Mark Menninger explained:

“The benefits of additive manufacturing for military organizations like the U.S. Navy include cost-effectively extending the life of strategic and tactical assets like aircraft while ensuring sustainment activities can happen quickly and from virtually anywhere. This contract, the largest government project for Stratasys to-date, continues to expand the presence of industrial 3D printing from Stratasys across the U.S. government.”

It appears the equipment will be used to produce parts closer to the demand, which will no doubt save time, shipping costs, and provide more flexible options. It’s possible the digital inventory approach could enable printing of new types of parts instead of using older styles made years previously using physical inventory approaches.

Stratasys explained:

“The printers will be located on bases in the United States and Japan with the potential to be used to produce end-use parts, tooling and training aids, as well as to assist the Navy in achieving its goal of using distributed additive manufacturing practices to maintain its fleet of aircraft across bases worldwide.”

Some thoughts on this development.

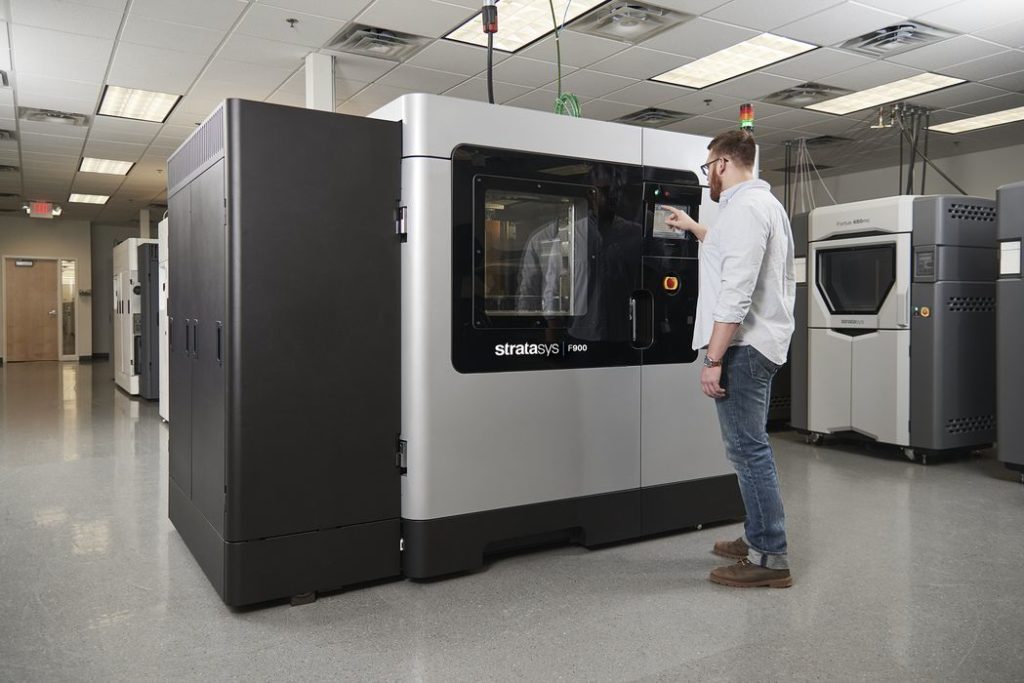

First, the F900 is Stratasys’ largest FDM 3D printer, with a massive build volume of 914.4 x 609.6 x 914.4 mm, almost a meter on two sides. With this device the US Navy will be able to print not only large single parts but also large batches of smaller parts as required. A huge range of possibilities are available.

The second thought is that there’s more to this deal than initially specified. Let’s look at this statement in particular:

“In addition to the printers, the contract includes initial support and sustainment, materials, and development of initial training for the supplied systems.”

This suggests that the deal will provide the US Navy with a batch of materials to start using with the machines. But it doesn’t say anything about further materials after the initial batch is consumed. In other words, the US Navy is, with this contract, committing to purchasing Stratasys materials for the lifetime of these machines.

That lifetime is certainly at least five years and more likely ten years. We don’t know how frequently the US Navy will be 3D printing, nor what kind of materials they will use — this could even be secret information. But we do know that the only major source for certified materials for Stratasys FDM equipment is Stratasys.

Stratasys has very likely established a reliable and long-term revenue stream with this equipment sale.

There’s one more thing: if the US Navy is successful in this move, there could be more sales of similar equipment (and subsequently materials) to the US Navy to expand the service. This depends on the demand for parts, but we’ve seen in other industries that growth is typical.

The US Navy success could also set a precedent for other branches of the military. If it works for the US Navy, would it work for the US Army? The Air Force? Probably, and the US Navy has already ensured the equipment and materials are certified for military use, so it’s an easier step for other branches to simply use more Stratasys equipment.

Good move, Stratasys!

Via Stratasys