Snapmaker announced a new 3-in-1 desktop 3D printer, the Artisan.

Snapmaker is well-known for their incredibly successful Kickstarter campaigns for previous devices. Their original device, the Snapmaker, sold over 5,000 units and raised US$2.3M. The Snapmaker 2.0 campaign sold over 7,000 devices and raised a massive US$7.9M. Snapmaker also runs some rather aggressive online marketing campaigns, so you have no doubt bumped into them at one point or another in your online activity.

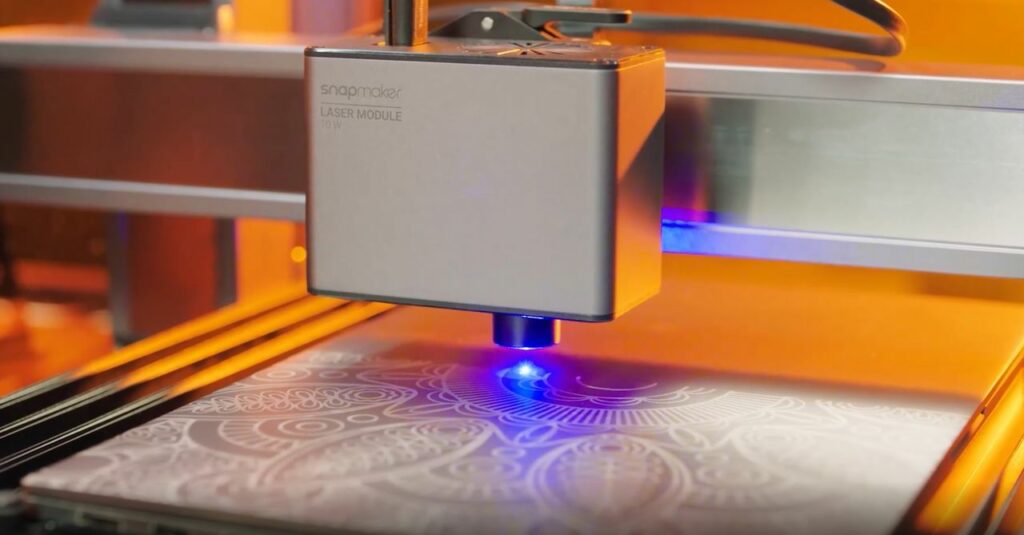

All of Snapmaker’s devices are “3-in-1”, meaning that they can provide three different making services: 3D printing, laser engraving and CNC milling. This is accomplished by simply swapping out the toolhead, as the motion system is the same for each function.

The idea is that one can use the different making methods to create more complex items by combining the technologies. Make some parts with one tool, and attach them to the others. Engrave patterns on surfaces, too.

What’s new with the Artisan? Plenty!

The original Snapmaker devices did offer the three functions, but they were generally underpowered and small, making them less useful. The Artisan changes that equation completely. It’s much, much larger and has upped the power of the toolheads significantly.

First, there’s the build volume. The Artisan has a massive 400 x 400 x 400 mm build volume. This is larger than the Snapmaker 2.0, which came in three build volumes, the largest being 320 x 350 x 350 mm. The larger volume means much larger parts can be made, opening up the possibility for more applications.

The Artisan has steel rails to guide the motion system in a more precise manner and its rigidity should increase 3D print quality and laser positioning accuracy.

One of the issues with many 3-in-1 devices is that the process of changing toolheads can be burdensome to the point where you just don’t want to swap them. The Artisan changes this by using quick-swap toolheads that apparently can be changed in less than a minute — without using any screws. That’s a huge advantage and will certain encourage makers to use all the tools at their disposal.

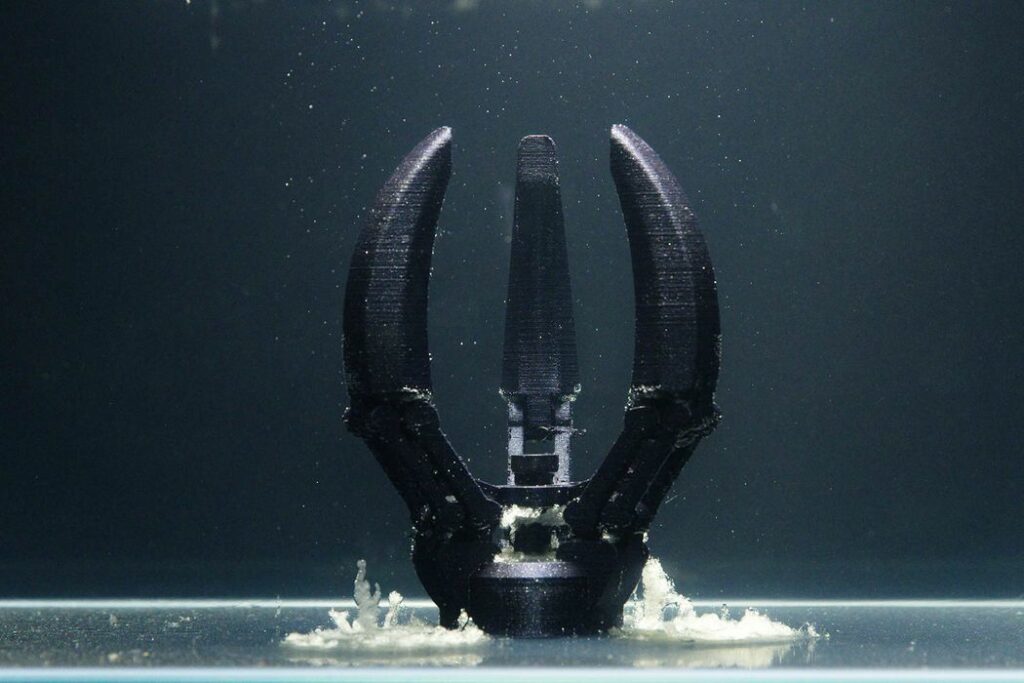

On the 3D print side, the Artisan now offers dual extrusion. This is extremely important, because the second extruder can use soluble support material, enabling the printing of highly complex objects. The support material can then be dissolved away in an unattended manner, even if in tiny crevices in the print.

Not only can you swap out the toolheads, you can also quick-swap the hot ends, which are automatically detected by the system to ensure coordinated materials use.

The dual 3D print extruders are designed to automatically lift when not in use, minimizing the possibility of print failure. This electric motor extruder switch is also far faster during printing than some dual systems’ method of moving to the side to mechanically switch extruders.

On the laser toolhead, Snapmaker has increased the laser power to a significant 10W. For those unfamiliar with lasers, many 3-in-1 devices offer tiny 1-2W lasers that may slightly engrave on wood and possibly cut cardboard. 10W is far greater and will offer much more laser engraving and cutting capability.

The CNC milling toolhead has also been improved, and now includes a 200W motor. The speed of milling is dependent on the power of the motor to grind through material, and the more power, the better. Snapmaker said milling can be up to 6X faster than previous models, and can now reach 18,000 rpm.

Snapmaker has also set the maximum temperature of the Artisan’s hot end to 300C, enabling the use of many typical engineering materials. The Artisan also includes a laser and dust isolating see-through cover, which just might also help 3D printing by capturing stray heat.

The Artisan includes a huge 7” wide color touchscreen that is curiously a separate module, perhaps to enable use while outside the enclosure.

Can you buy an Artisan now? Not quite. Snapmaker is to open up pre-orders on August 9th, so stay tuned for that date.

Via Snapmaker