SPONSORED CONTENT

Jigs and fixtures are a staple application in 3D printing, but there’s much to know when using them.

What is a Jig or Fixture?

Simply put, a jig or fixture is simply an appliance that is used to guide a manufacturing process. It might hold two or more parts in alignment while being joined, or perhaps provide correct spacing for drilled holes.

Jigs and fixtures are traditionally used but were traditionally made by hand or with conventional techniques. Since they are not part of the actual end-product, it’s possible to change them if someone has a better concept that could improve manufacturing operations.

Because these objects are used to help make potentially millions of products, they are quite critical to the operation. Any mistake in a jig or fixture could result in vast numbers of incorrectly made products.

Challenges With Jigs and Fixtures

Because the products being produced in a manufacturing operation may be using any type of process, environment, or sequence, the jigs and fixtures used could be subjected to the same conditions.

This means that a jig or fixture could be required to survive millions of uses, extreme heat or cold, radiation, vibration, chemical exposure, or a combination of environments. In some cases a jig or fixture may have to be electrically resistant or be unaffected by flames or smoke. For example, consider a jig that might have to hold two parts together while proceeding through a paint booth and subsequent hot drying sequence: both chemical and heat resistance would be required.

Because of these factors, the process of creating a jig or fixture requires very careful consideration. The right materials must be used, otherwise, the jig or fixture may not succeed in its target environment.

3D Printed Jig and Fixture Advantages

One may think that 3D printing has no role in mass manufacturing, but in fact it is increasingly important. 3D printing is being used to create complex jigs and fixtures used to optimize the mass manufacturing process. Here’s a video overview of using 3D printed jigs and fixtures in a manufacturing environment:

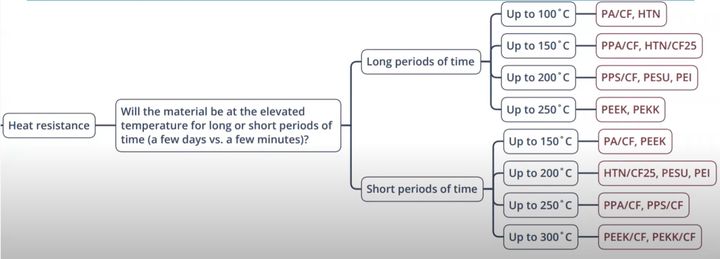

The choice of material is critical, and that’s why 3D printer manufacturers such as Essentium have launched a wide variety of engineering materials. By having many choices, one can better select the optimal material for a given jig or fixture. Here’s a chart showing how one would choose a material when considering heat resistance:

Similar decision trees for other properties can be used to narrow down the choice to the best material for the job.

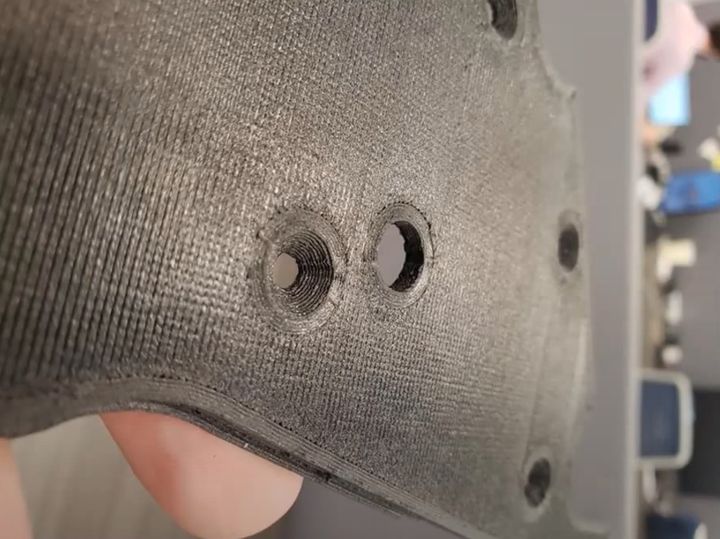

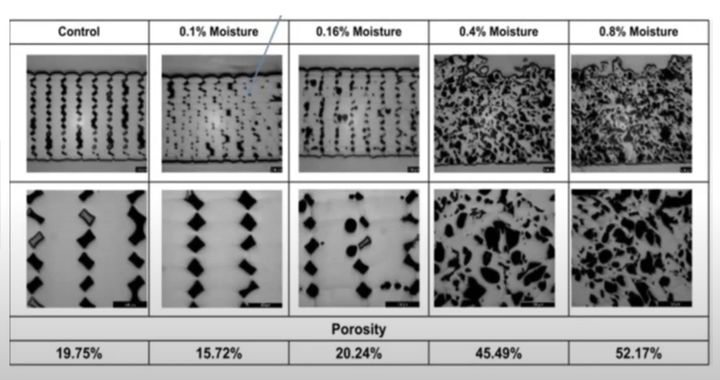

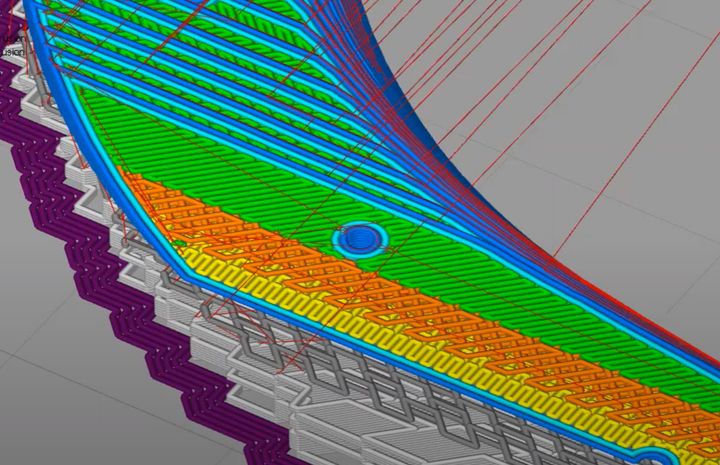

Another factor is the printing of the jig or fixture. 3D print jobs can be tweaked to build the best possible results by ensuring the part meets the most important requirements, such as surface quality, dimensions within tolerance, or mechanical strength.

This usually requires an iterative process where the slicing parameters are slowly tuned to dial in the best output. This is a complex process, particularly for those new to 3D printing, and may require assistance from a 3D printer provider. However, with practice, this process becomes more natural and experienced 3D printer operators will be able to quickly find the best print profile for a given part.

Essentium’s Will Blalack provided an excellent webinar where he reviews this process from end to end. He discusses common issues in designing and producing jigs and fixtures, choice of materials, part design, and more by examining interesting real-life jig and fixture applications.

There’s another key advantage of 3D printed jigs and fixtures, and that’s the ability to iterate.

While traditional jigs and fixtures suffer from long lead times when produced using traditional methods, a 3D printed item can be produced in only a couple of hours once the design is finalized. This means that a manufacturing operation could frequently change the design of its jigs and fixtures, particularly if someone realizes there’s a better way to do so. A new design can be produced and quickly implemented.

A final, and perhaps most important, advantage is 3D printing’s ability to produce very complex objects with ease. This means that the normal constraints of jigs and fixtures are lifted and designers have the freedom to create, for example, a jig that holds more parts in more orientations. Depending on the specific application this could save a considerable amount of effort and time on an assembly line.

It’s not surprising that many manufacturers are turning to 3D printed jigs and fixtures.

Via Essentium