Lithoz seems to be on a roll, expanding in several directions.

The Austria-based company may not be as well known as some in the industry, but they seem to be on track to change that with a series of moves in the past year to raise their profile and scope.

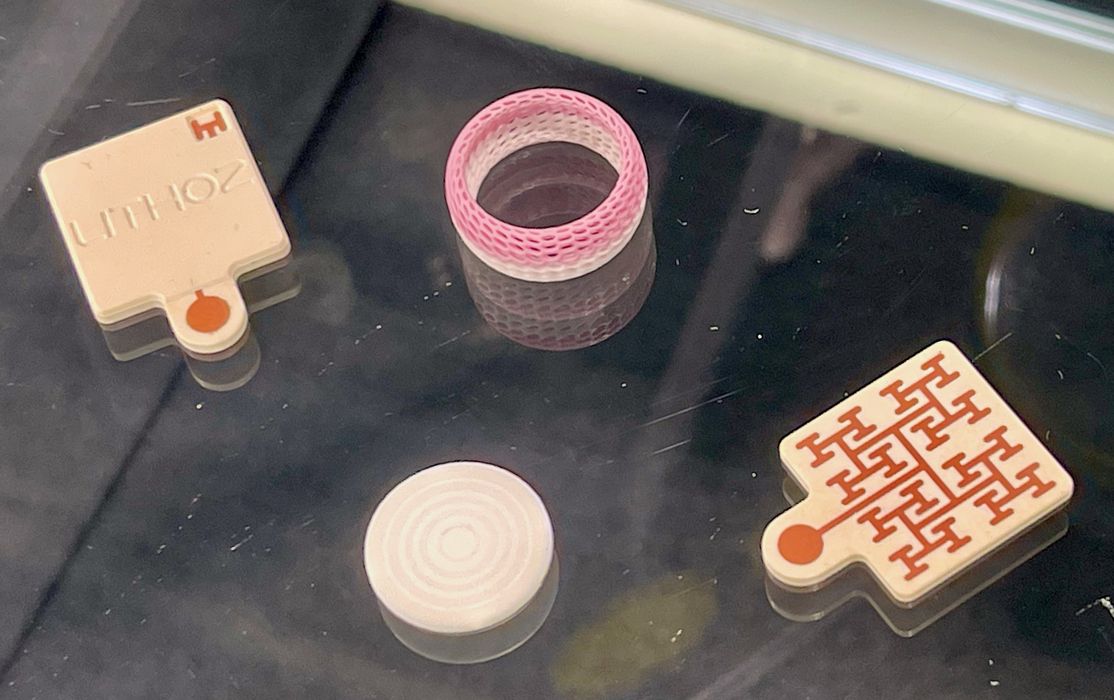

The company specializes in ceramic 3D printing, which, although it’s a relatively small niche, is rapidly growing as industry discovers new applications for ceramics. Ceramic prints have the advantages of being extremely hard, chemically resistant and also can withstand tremendous heat.

Lithoz has acquired a couple of new related 3D processes in recent months, and only a few weeks ago Lithoz announced they’ve signed a deal with SiNAPTIC.

SiNAPTIC is a Colorado-based 3D print service specializing in ceramics for the healthcare and industrial applications.

The deal involves SiNAPTIC acquiring not one, but seven Lithoz CeraFab S65 machines. The S65 has a build volume of 102 x 64 x 320 mm, and can print layers as small as 0.10mm with 0.04mm XY resolution. The S65 can 3D print in a wide variety of ceramic materials from Lithoz’s catalog.

It appears they are acquiring medical certifications and are thus able to produce new medical devices using the technology.

Lithoz tells us they have considerable interest from other industries, including semiconductor, nuclear and even the military. They currently have multiple customers performing significant production using Lithoz technology.

On the materials side, Lithoz has just launched a new ceramic, Aluminum Nitride. Lithoz recommends this new material for industrial applications and semiconductors, as it has a thermal expansion coefficient similar to silicon.

Lithoz mentioned to us that they have been able to print metal and ceramics together, as well as copper and glass. This multimaterial capability is extremely interesting, as one could imagine entirely new applications emerging from it. I am pretty sure no other company is able to provide multimaterial capability with ceramics, aside from some experiments from XJET.

The SiNAPTIC partnership is a major step for Lithoz, and adds to their scope. When we first encountered them several years ago they were only able to focus on Europe, but now they have spread their technology to a much wider range. By adding materials and new 3D printing processes, it enables them to address even more customers.

Via Lithoz

“I am pretty sure no other company is able to provide multimaterial capability with ceramics, aside from some experiments from XJET.”

That’s not accurate at all… production multi-material capability with ceramics has been done for several years now. Just check out some of the major players patent portfolios and you can gleen what they’re doing from them. I have test parts from when we started developing our own process a decade ago.