Charles R. Goulding and Randall Rothbort consider how 3D printing can help the food business bounce back post-pandemic.

3D printing has been adopted by many industries; however, it has a particularly inventive outlook for the restaurant food equipment business. This industry is focused on developing increasingly effective and efficient equipment to assist restaurants in their cooking process. Particularly as restaurants begin to return post-pandemic and some shift to more convenience-focused experiences, there has been a noted push for more inventive products to assist restaurants. While currently 3D printing is used to replace parts in equipment, and even to develop components of dishes, it has the potential to be used in the creation of entire items of food. These manufacturers stand to benefit by offering unique and innovative products that improve the faculties, efficiency, and products of their clients.

Various manufacturers such as Welbilt, Illinois Tool Works (ITW), Middleby, and Dover/Hill Phoenix, have begun incorporating significant 3D printing technology throughout their manufacturing and refurbishing process, which is detailed in our prior article Cooking Up A New Recipe For The Reconditioned Restaurant Food Equipment Business With 3D Printing. This technology can similarly be used to allow 3D printing service providers to update older equipment to better fit the needs of restaurants post-pandemic.

ITW has begun hiring engineering candidates specifically with experience in 3D printing and manufacturing as it continues to become a growing aspect of the business, even using this new knowledge in the production of 3D printed plastic components for masks during the COVID-19 pandemic. 3D printing allows these companies to greatly expand their manufacturing capabilities, and incorporate new methods and parts that were previously unavailable.

Dover has made several investments into the 3D printing market, specifically into Tiertime Technology, a notable desktop 3D printer manufacturer in China. Dover executives, such as Michael Y. Zhang, have discussed how they see 3D printing as an avenue to make Dover a leader in the industrial market. Incorporating 3D printing into their equipment manufacturing process can greatly improve their product quality and efficiency of production.

3D printing also has growing uses in the culinary field itself. Chefs have begun to 3D print parts of dishes, such as a seafood puree “coral” that is made by Chef Paco Perez at La Enoteca. Perez uses a 3D printer to produce the coral pieces perfectly for each dish made. Similarly, 3D printing can eventually be used to print more significant portions of a dish, allowing dining establishments to include unique ingredients and nutrients in unique ways. 3D printing also has significant potential to improve food sustainability, as it minimizes waste and allows rarely used ingredients to be used for more industrial purposes.

Automation is another significant addition to the restaurant equipment industry. Since the start of the pandemic pushed people indoors, there has been a steadily growing interest in convenience-focused restaurant experiences, most notably the growth of ghost kitchens (delivery-exclusive kitchens with no storefront).

The implementation of cloud-computing technology into equipment allows restaurants more accurate cooking, improved quality, and significant cost savings, and specific benefits in the near automation required for ghost kitchens and other delivery-focused dining experiences. Furthermore, this technology helps to make training easier and the machines themselves more accessible to new employees, as many restaurants are finding the equipment has assisted in employee retention and performance. 3D printing is a logical progression from this, as it merges seamlessly with automation, and can be leveraged to automatically produce products as needed throughout the culinary process without the need for intricate work or expertise by an employee. This allows both for improved products as well as improved efficiency.

The Research & Development Tax Credit

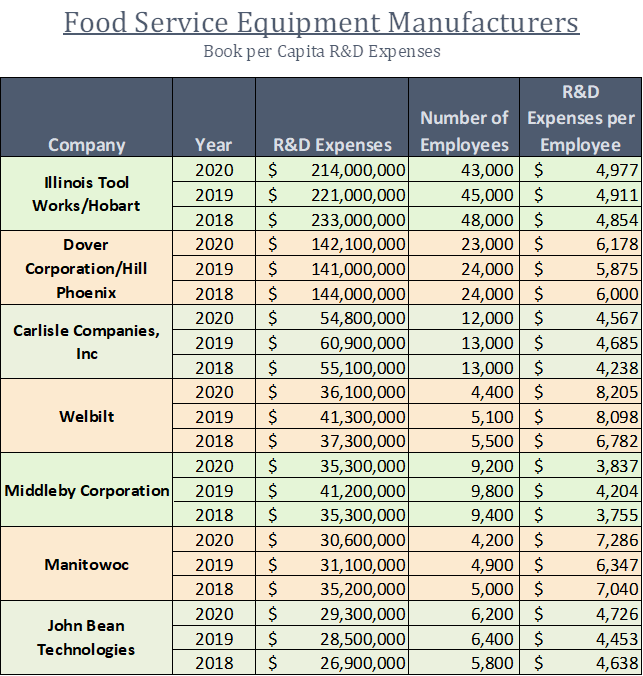

Whether used for prototyping or manufacturing, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits. The food service equipment industry is one with significant R&D expenses, all of which can apply for the R&D Tax Credit.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum tax for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Conclusion

As more culinary and restaurant equipment manufacturers continue to innovate to accommodate the drastically changing restaurant landscape, their businesses will flourish. 3D printing is at the forefront of this, as it allows restaurants and dining companies to produce unique products, as well as allow manufacturers to improve their manufacturing capabilities. This innovation will continue to drive the industry forward, especially as the industry continues to bounce back post-pandemic.