There’s a reason why Creality’s CR-30 belt 3D printer needs attention.

Last week Creality launched what could be the biggest-selling belt 3D printer yet seen on Planet Earth, and sales seem to be proceeding smoothly, according to their 3DPrintMill Kickstarter launch.

Belt 3D Printers

Belt 3D printers are a unique branch in the 3D printing tree, as they have two very important capabilities. Using a moving conveyor belt as the print surface, they are able to produce objects continuously, one after the other without end — or at least until you run out of filament. They can also 3D print objects that are vastly longer than the machine itself by simply continuing to build as the object “grows” out of the machine on the belt.

You might think this is an unusual curiosity among 3D printers, and perhaps you’re correct — today. These days virtually all 3D printers are single-plate systems capable of printing only one job within a constrained build volume. That’s what people are accustomed to using.

I think this attitude will change.

Belt 3D Printing Transformation

For those of you who have not yet used a belt 3D printer, I suspect you may not understand the staggering transformation that occurs with belt capabilities.

I first learned of this concept ten years ago by using MakerBot’s ill-fated Automated Build Platform. My MakerBot CupCake, one of the first home 3D printers, was in reality a terrible device by today’s standards.

Yet, in spite of its limitations, it became something very different when the ABP was added. Suddenly this little device became a manufacturing engine capable of producing many, many parts, all while being unattended. And I did use it like that — I made hundreds of little prints continuously, until the belt warped due to repeated heat exposure. That was the downfall of the ABP.

Since then I’ve always wondered why a belt-style 3D printer didn’t become the standard way of building a 3D printer. I’ve even proposed a caterpillar-style belt and more recently speculated on the future of belt 3D printing.

Why Few Belt 3D Printers?

Why are there so few belt 3D printers? Perhaps it’s due to the technical challenges in designing such a system. Perhaps it’s the cost of the resulting device.

Or worse, perhaps it’s because people just don’t see the need for the capability.

For me, this doesn’t make sense. Let me prepare an analogy for you: Would you buy a 2D paper printer that required you to unload the machine before you could print a second page?

Of course you wouldn’t. That wouldn’t make sense.

Then why aren’t 3D printers treated the same way? Why do we persist in buying devices that always require significant human intervention on each and every job? Why don’t we want a machine that could at the very least unload itself and make ready for the next job?

This should be normal behavior for 3D printers, but it isn’t.

That is, until belt 3D printers arrived. Or, I should say, “are arriving”, as they are just now emerging from the shadows of development and becoming known by the wider community.

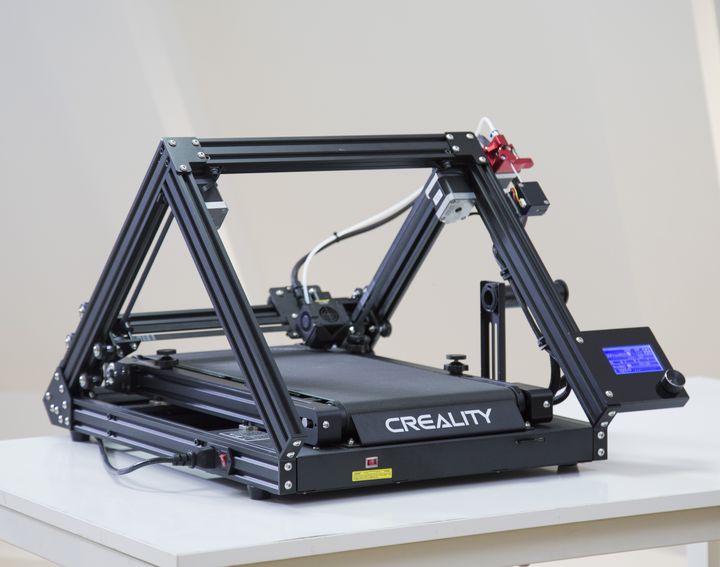

Creality CR-30 & Open Source

Of the several recent launches of belt 3D printing, I am most concerned with the Creality CR-30, which has one thing that the other belt projects do not: the possibility of being open sourced.

The CR-30 is designed by Creality, who were inspired by an open source design that turned out not commercially viable. Their engineers have transformed the concept into one that has been implemented in a manner that is fully manufacturable at scale, and yet carries a reasonable purchase price.

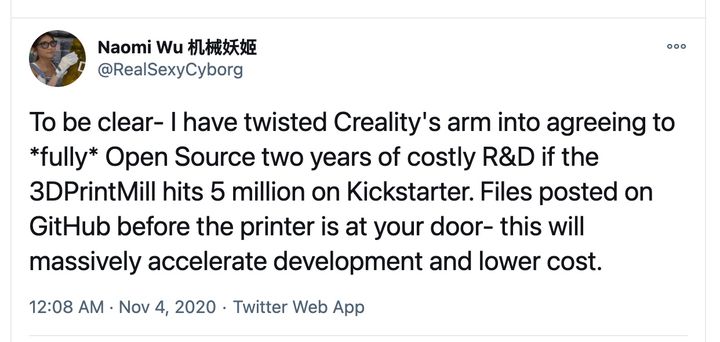

It’s been launched on Kickstarter to help with visibility in the West, and seems to be doing well. However, there’s something else going on here. According to Creality 3DPrintMill promoter and SuperMaker Naomi Wu:

That’s correct: if Creality hits US$5M on their launch, the company is set to open source the project. (As of the time of publishing, the Kickstarter is over US$1.1M with 17 days left in the campaign.) You can read more of Wu’s thoughts on this matter in our exclusive interview.

If this indeed happens it could be a massive breakthrough for the belt 3D printing concept. That intellectual property could enable others to more rapidly get into the belt 3D printer business and potentially develop even more powerful and unique designs. Sure, they’d compete against Creality, but that in turn would spur them on to improve the design further.

Today there’s so few belt 3D printers available the level of competition among them is relatively low, and they really compete against “normal” 3D printers. But if it wasn’t one could imagine in the future seeing belt 3D printers having full enclosures, object catchers, able to 3D print in engineering materials, multi-material options and much, much more.

Wu believes in belt 3D printing. So do I, and so do the many who have tried it.

But what about the rest of you? When will you try belt 3D printing to try to understand its amazing power? Maybe now the time to start?

Via Creality and Kickstarter

Please also check the ifactory3d one. Its on kickstarter this very moment and it has some interesting features while being in the same price range as the cr-30.