Researchers at Fraunhofer ILT have developed a revolutionary method of 3D printing metal.

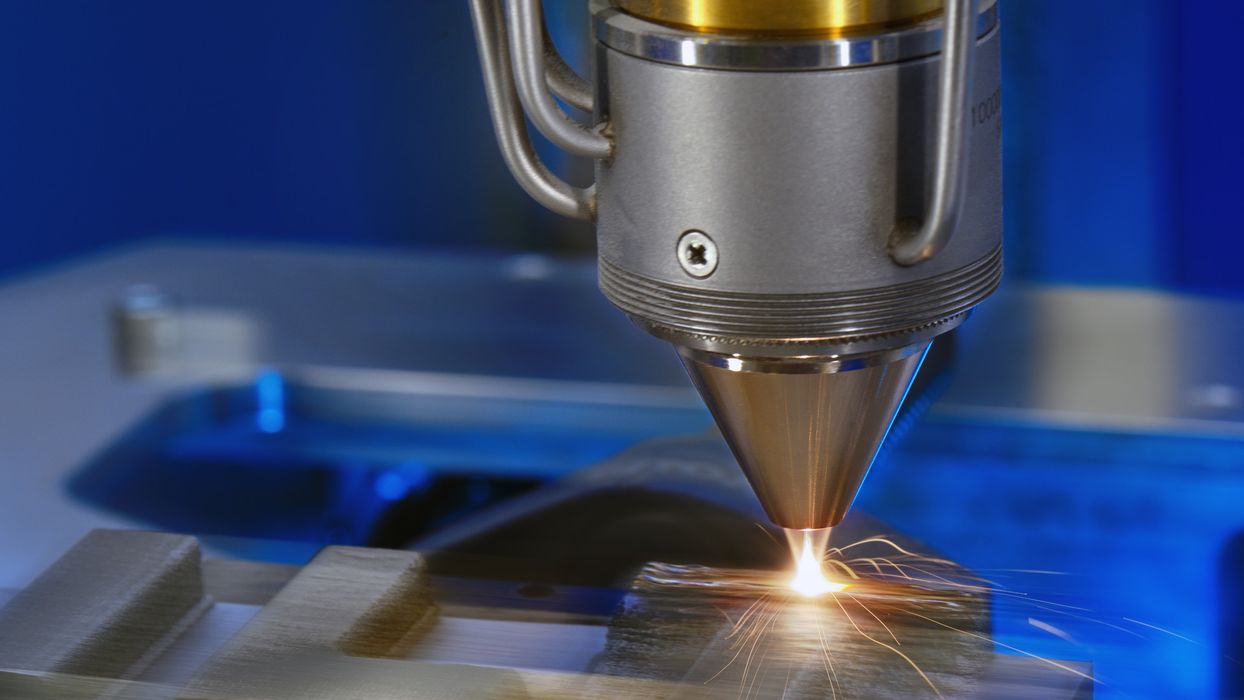

Fraunhofer ILT (the “ILT” stands for Institute of Laser Technology, by the way) has been developing a technology known as EHLA for several years. It’s a method for deposition of metal using, obviously, lasers. Powder is sprayed out and hit with a powerful laser beam that instantly melts the metal, which is then deposited on a nearby surface.

That doesn’t sound revolutionary, but read on.

EHLA

EHLA differs from current deposition systems in that it can operate much, much faster. According to Fraunhofer ILT, conventional deposition methods range from 0.5 to 2.0 meters per minute (8-33mm/sec) of surface coverage, as the deposition toolhead moves along.

EHLA is faster: 50 to 500 meters per minute (833-8333mm/sec). That’s 100-250X faster!

Wait, there’s more. The minimum layer thickness is only 0.02mm, whereas conventional deposition systems can only reach 0.5mm. Thinner layers means less material is used for coatings.

Finally, EHLA uses far less energy because the metal powder is heated while it travels in the air, rather than heating it on the target surface, where some heat is wasted as it is conveyed into the structure. The fully liquid metal droplets hit the target surface accurately and with less heat energy required.

Before you get too excited, there is a problem: EHLA has only been used for 2D applications, such as applying coatings to existing parts. That’s certainly an incredible technology on its own, but now things could change dramatically.

EHLA 3D

Fraunhofer ILT has been working to leverage EHLA into a 3D printing system. They call the process “EHLA 3D”.

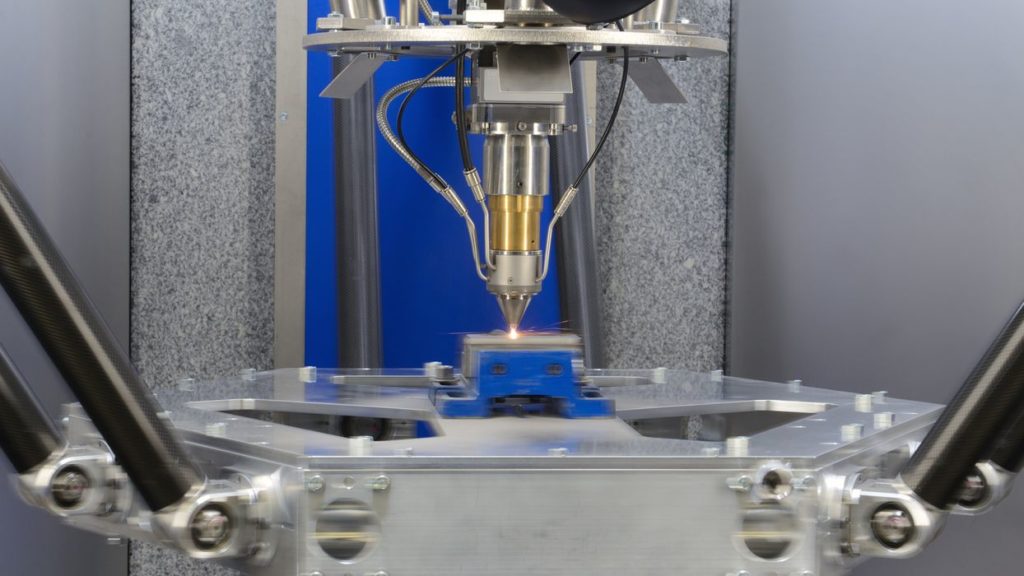

This is a process that’s been done many times in 3D printing: a deposition process is made “3D” by simply placing a toolhead in a motion system. But with EHLA there are new challenges: extreme speed introduces many issues, not the least of which is accuracy. At high speeds, a poorly-designed motion system might introduce vibrations when the direction of movement is rapidly changed.

It seems, however, that the researchers have overcome this challenge and developed a unique “tripod” motion system that can indeed handle the very rapid speeds of the process. This means that EHLA 3D could in theory print metal objects at very high speed, with great accuracy and high resolution, and possibly at low cost, too.

Researcher Jonathan Schaible said:

“Central to this are, for example, process monitoring concepts and automated path planning tools, but parameter variation remains the most important in the laboratory for the time being. During process development, all parameters must be precisely coordinated: speed, laser power and powder quantity depending on the material combination being processed in each case. There is still a lot of experimental and empirical preliminary work to be done. However, the first interested parties from industry have already put out their feelers. So we know we are on the right track.”

EHLA 3D Destroys

While it’s very clear EHLA 3D can create objects, it could also destroy.

Not objects, but companies.

There are a number of large existing players in the 3D print industry that base their business on one of two capabilities:

- Printing large, low resolution objects at slow speeds

- Printing small, high resolution objects at slow speeds

These businesses have grown over in some cases decades, and now provide industry (especially aerospace and automotive) with the ability to build advanced metal parts. That will grow significantly in coming years as the use of lightweight parts becomes the norm.

These industries will buy plenty of metal 3D printers, but should EHLA 3D be successfully commercialized, it may be that buyers choose a technology that’s faster, cheaper and just as effective.

And that could leave many of the existing metal 3D printers companies on the sidelines.

Via Fraunhofer ILT (Hat tip to Benjamin)