3D print parameters are a bit of a mess these days.

Print parameters are the settings used in a specific 3D print job that enable successful completion. While that sounds straightforward, the situation is actually quite a bit more complex.

To achieve success there must be a near perfect match between three factors: machine, material and parameters.

Here is where the problem comes in: the number of possible print parameter configurations is a very large number. Consider the following equation:

Number of configurations = Number of Materials X Number of machines (and modified machines)

I ask you, “how many different machines are there?” The answer is several hundred. The number of possible materials is also numbered in the hundreds, leading to a very large number of configurations.

Some 3D printer manufacturers have attempted to overcome this issue by implementing databases of print parameters that can be linked to slicing software. This allows the operator to pick the material and machine and (hopefully) there is a match by means of a specific print parameter configuration for that combo. These approaches definitely simplify life for those 3D printer operators.

To fill those databases, 3D printer manufacturers have to accept suggestions from trusted operators, or perform a vast amount of testing themselves. It’s a lot of work, either way, and only a few companies have managed to create extensive databases with a reasonable number of name-brand materials.

The situation is a bit different for materials providers, who don’t have the ability to set up their own slicing software and databases. For them they have to approach those 3D printer manufacturers having parameter databases and submit their suggestions.

The problem comes in with resin 3D printers, as there are very few of the dozens of desktop MSLA 3D printers offering such features.

What does a resin manufacturer do? The answer can be seen at one such manufacturer, Liqcreate. The Netherlands-based company manufactures 19 different 3D printer resins, including materials suitable for casting, dental applications, and general purpose mechanical parts.

Now consider this: on how many different resin 3D printer models might their resins be used? I would suggest at least a hundred, and that number would increase week by week as new models emerge. This suggests that Liqcreate would have to identify over a thousand correct print parameter combinations.

How do they do this?

They’re taking a very straightforward approach: they’re simply listing them on their website in tabular form. To their credit, the company actually lists print parameters for 65 different machines models by my count. Here are the machines they cover:

- Ackuretta FreeShape 120

- Ackuretta Dentiq

- Anycubic Photon

- Anycubic Photon Zero

- Anycubic Photon Mono

- Anycubic Photon Mono 4K

- Anycubic Photon Mono SQ

- Anycubic Photon Mono SE

- Anycubic Photon Mono X

- Anycubic Photon Mono X 6K

- Asiga Max

- Asiga Pro 4K

- Atum3D DLP Station 5

- Beam3D Prism

- Carima IM2

- Creality LD-002R

- Creality LD-002H

- Creality LD-006

- Creality Halot-One

- Creality Halot-Sky

- Cubicon Lux

- DWS DigitalWax 028

- Elegoo Mars

- Elegoo Mars 2 & Mars 2 Pro

- Elegoo Mars 3

- Elegoo Saturn

- EPAX X1N

- EPAX X10 Color

- EPAX X10 & E10 Mono

- EPAX X1K E6

- Flashforge Foto 13.3

- Formlabs Form 1+

- Formlabs Form 2

- Kelant S400

- Kudo3D Bean

- Miicraft Ultra

- Miicraft Prime

- Miicraft 125

- Orange Longer 30

- Peopoly Moai

- Peopoly Phenom L

- Peopoly Phenom Noir

- Peopoly Phenom Prime

- Phrozen Shuffle

- Phrozen XL

- Phrozen Transform (RGB)

- Phrozen Sonic Mini & XL 4K

- Phrozen Sonic Mini 4K

- Phrozen Sonic Mighty 4K

- Prusa SL1

- Prusa SL1S Speed

- Qidi Tech Shadow 5.5S

- Qidi Tech i-Box Mono 4K

- Shining3D AccuFab-D1

- Shining3D AccuFab-L4D

- Shining3D AccuFab-L4K

- Sprintray Moonray S & D

- UnionTech Cute300

- Uniz Slash

- W2P Solflex Series

- W2P Sollab Series

- Wanhao Duplicator 7

- Wanhao GR1

- XYZ Nobel 1.0A

- Zortrax Inkspire

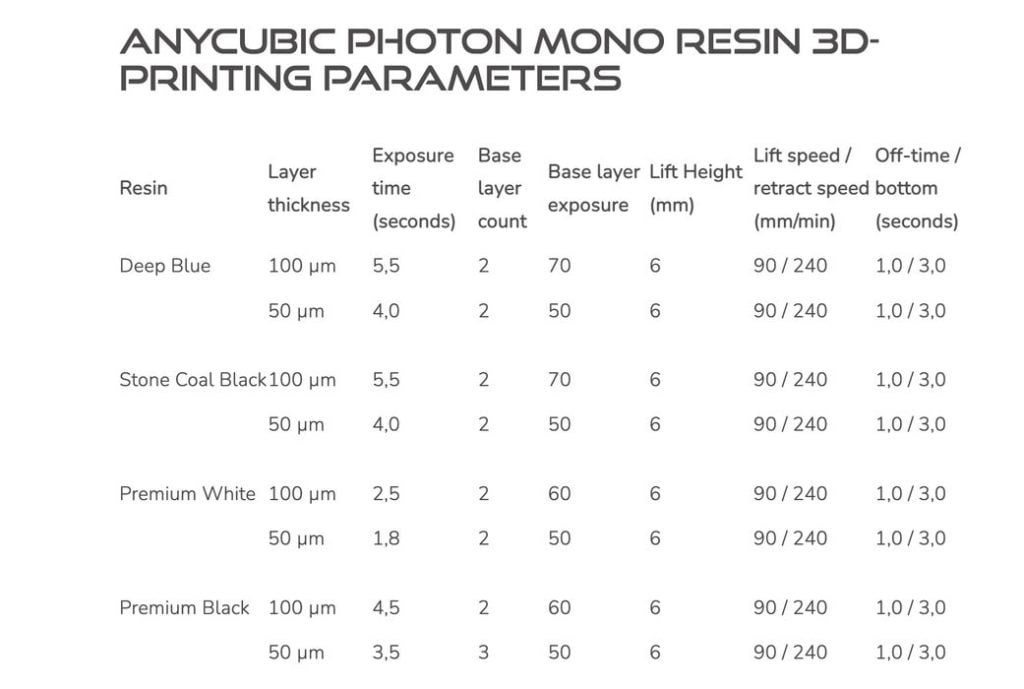

What do you get from Liqcreate? Here’s an excerpt from one of their material parameter pages:

They provide parameters for two basic configurations for each printer: a 0.10mm and 0.05mm layer size, which, as you can see, does change the parameters slightly. These lists continue for each of the current Liqcreate materials, and 3D printer operators can simply cut and paste them into their slicing software.

Not all the configurations filled yet; several are blank, but I presume Liqcreate intends on filling them at some point.

While this approach works, it is quite manual. I believe eventually someone is going to have to create a centralized databases of machines, materials and parameters that can be dynamically linked from any slicing software tool. That’s a bit of a dream at this point, but it would certainly make 3D printing life easier — for everyone.

Via Liqcreate