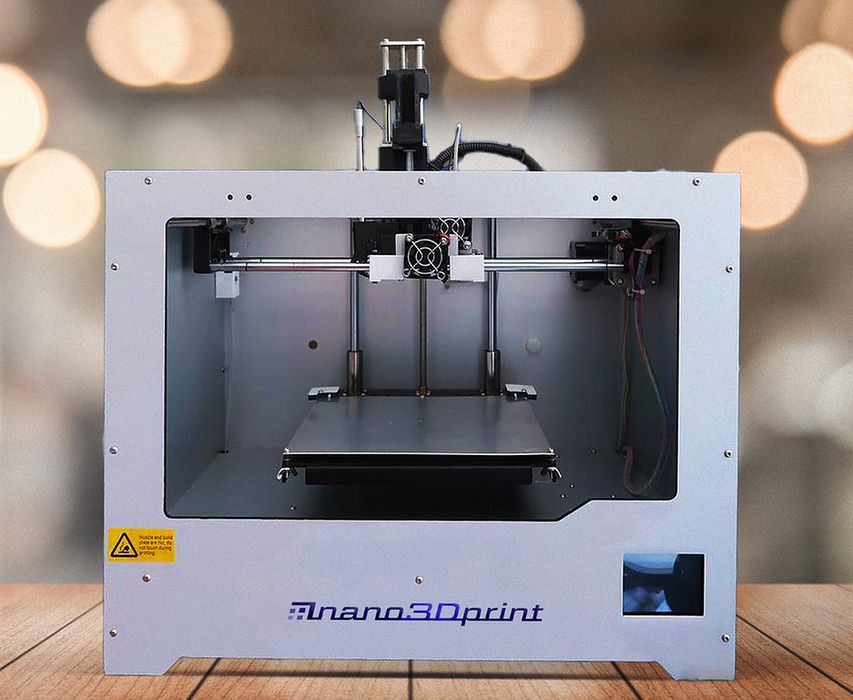

You likely haven’t heard of nano3Dprint’s A2200 3D Multimaterials electronic printer.

The company, formed in 2015, produces two unique 3D printers. One is the D4200S, which performs nanoscale 3D printing. The other is of more interest today, the A2200.

nano3Dprint bills this device as an “electronics printer”, and that’s quite true: it can 3D print solid objects in the usual 3D print fashion, but simultaneously 3D print conductive material.

The A2200 does this by including a normal FFF extruder alongside a special paste extruder. The paste extruder is intended to print “functional inks” that are conductive materials made from gold, silver, copper or other metals with conductive properties.

The idea is to design more functional objects that include wiring directly printed into the geometry. For example, this print made by nano3Dprint is a flashlight that has wires printed between the battery compartment and the LED light source.

That’s a simple example, but with this capability it might be possible to design and print complex electronic housings for smart devices. Another example might be a UAV design where wiring is embedded in the airframe.

nano3Dprint said you can:

“Print wires, electrodes, interconnects, contacts, electrical leads, and power applications.”

The A2200 can use many standard 3D printing filaments, including PLA, ABS, and “high performance materials”. This could include carbon fiber reinforced material, but evidently you must select a higher grade A2200 equipped for that material.

For polymers, nano3Dprint said the A2200 can handle the following in its 214 x 186 x 160 mm build volume:

- Conductive filament

- Carbon Fiber filament

- PLA

- ABS

- POM

- Red Bronze

- PVA

- HIPS

- Wood

- PETG

- Nylon (PA)

- PC

- TPU

- PLA+

- Moldlay

- nano3Dprint high conductive filament

- And more

This is quite a capable machine, even if you’re looking only at the polymer side.

The paste extruder is able to print inks with a “wide range of viscosities”, which opens up many possibilities. nano3Dprint also states the paste extruder can 3D print ceramics, but I suspect this is not done in conjunction with the polymers. This is because the ceramic material would have to be fired to be finalized, and that would vaporize the polymers. However, it’s likely possible you can print small pure ceramic objects.

Another interesting possibility is to use “glue”. The idea is to print a layer of polymer, then a layer of adhesive, then another layer of polymer. This might be able to overcome FFF 3D printing’s fatal flaw: poor layer adhesion.

An intriguing feature is a video inspection system. nano3Dprint explains:

“The A2200 features a real-time magnifying video inspection system for more precise adjustment control of our dispensing system. A2200 also boasts its accuracy in layer height, surface finishing, tolerance, and roundness for standard 3D printing.”

It’s not entirely clear how this works, but if so, it could be valuable to operators.

The print surface is heated glass, which can be removed.

For the software workflow, nano3Dprint said you can use “your favorite slicer”, but recommends Simplify3D and Repetier. However, I suspect most operators would want to use either PrusaSlicer or Ultimaker Cura, and they’d likely work if configured properly.

Finally, nano3Dprint has priced the base A2200 3D printer at just under US$5K, making it more accessible than some other electronic-capable 3D printers.

Via nano3Dprint