I’ve been investigating the rather quiet company Seurat Technologies, which is developing a new metal 3D printing process.

I can’t tell you very much, however, as the company is quite secretive about their plans. The only relevant image I can find is the one at the top, supposedly showing their metal 3D printing process underway.

Seurat Technologies

What do we know about them? Well, they launched way back in 2015, five years ago and counting. But we have not yet seen any products emerge from the company.

They have a core staff that has experience from Lawrence Livermore National Laboratory, where advanced 3D printing things have been happening for many years, so it’s possible some ideas inspired by that organization have made their way into Seurat Technologies.

They are developing a new metal 3D printing process that appears at first to be related to the standard PBF approach. They say:

“Our technology is not an iteration on existing thinking. We’ve fundamentally reimagined Metal AM.

Think telegraph to telephone. Propellers to jets.

Vacuum tube to transistor.”

Sounds impressive, but what could they be up to?

While their website is essentially void of any technical information, there are some clues that can be found elsewhere. For example, they had been selected to participate in a US government project in 2018, and the summary of their submission is as follows:

“Metal additive manufacturing is growing rapidly and is of immense interest worldwide to decrease weight, increase functionality and improve manufacturing efficiency. Laser powder bed fusion additive manufacturing (PBFAM) printers from today’s market leaders routinely make high-value parts. However, today’s machines also suffer from low productivity and have major quality problems largely due to spatter, defects, and residual stress. Seurat’s novel printers operate by area printing enabling a high degree of spatial-temporal laser intensity control. Careful tuning of thermal history can lead to minimal spatter, ability to control microstructure, and decreased residual stresses. We propose to use high-speed video, material analysis and multiphysics modeling to characterize the effects of the interaction between the lasers and powder and to elucidate the underlying physics. Simulation guided advancements to Seurat’s area AM printing can impact energy-related technologies such as light-weighted vehicles, heat exchangers, inventory reduction and novel high-performance parts.”

Aha — it would seem that they are indeed using PBF, but doing so in unique ways. What else can we find?

Seurat Technologies Jobs

While there are no currently available job postings on the Seurat Technologies site, I found one on the net in which they sought an additive manufacturing process engineer to “fully execute the printing process”. The purpose of this operator apparently was to conduct extensive testing of a metal 3D printer.

Seurat Technologies Patents

Seurat Technologies says they have obtained a number of patents. I found them, and here they are:

- 20170120387US Part Manipulation Using Printed Manipulation Points Filed: Oct 27, 2016 (Pending)

- 10518328US Additive manufacturing system and method Filed: Oct 27, 2016 (Granted)

- 20170120334US Chamber Systems For Additive Manufacturing Filed: Oct 27, 2016 (Pending)

- 20170120537US CHAMBER SYSTEMS FOR ADDITIVE MANUFACTURING Filed: Oct 27, 2016 (Pending)

- 20170120335US Variable Print Chamber Walls For Powder Bed Fusion Additive Manufacturing Filed: Oct 27, 2016 (Pending)

- 10596626US Additive manufacturing system and method Filed: Oct 27, 2016 (Granted)

- 20170120332US Additive Manufacturing System And Method Filed: Oct 27, 2016 (Pending)

- 10583484US Multi-functional ingester system for additive manufacturing Filed: Oct 27, 2016 (Granted)

- 20170120333US Enclosed Additive Manufacturing System Filed: Oct 27, 2016 (Pending)

- 20170120530US Dynamic Optical Assembly For Laser-Based Additive Manufacturing Filed: Oct 28, 2016 (Pending)

- 20170123222US POLARIZATION COMBINING SYSTEM IN ADDITIVE MANUFACTURING Filed: Oct 28, 2016 (Pending)

- 20170120336US Long And High Resolution Structures Formed By Additive Manufacturing Techniques Filed: Oct 28, 2016 (Pending)

- 20170123237US LIGHT RECYCLING FOR ADDITIVE MANUFACTURING OPTIMIZATION Filed: Oct 28, 2016 (Pending)

- 20170120538US RECYCLING POWDERED MATERIAL FOR ADDITIVE MANUFACTURING Filed: Oct 28, 2016 (Pending)

- 20170232515US Additive Manufacturing Simulation System And Method Filed: Jan 25, 2017 (Pending)

- 20170232557US Additive Manufacturing, Spatial Heat Treating System And Method Filed: Jan 30, 2017 (Pending)

- 20170232637US Additive Manufacturing, Bond Modifying System And Method Filed: Jan 30, 2017 (Pending)

- 20180326664US Solid State Routing Of Patterned Light For Additive Manufacturing Optimization Filed: May 11, 2018 (Pending)

- 20180326663US Switchyard Beam Routing Of Patterned Light For Additive Manufacturing Filed: May 11, 2018 (Pending)

- 20200189038US Additive Manufacturing System For Object Creation From Powder Using A High Flux Laser For Two-Dimensional Printing Filed: Dec 12, 2019 (Pending)

- 20200198060US Additive Manufacturing System Using A Pulse Modulated Laser For Two-Dimensional Printing Filed: Dec 19, 2019 (Pending)

- 20200164438US Multi-Functional Ingester System For Additive Manufacturing Filed: Jan 31, 2020 (Pending)

While it’s far too tedious to work through each of these, it’s quite clear this company has been devising some intriguing approaches for a variety of aspects related to metal PBF 3D printing.

That said, there are a couple of very interesting patents. One, 10518328, describes a laser system that uses multiple different wavelengths. I’ve not heard of that approach previously.

Another, 20170120335, describes how temporary walls can be 3D printed during a job to contain powder. I’m not sure why that’s important, but it does seem quite interesting.

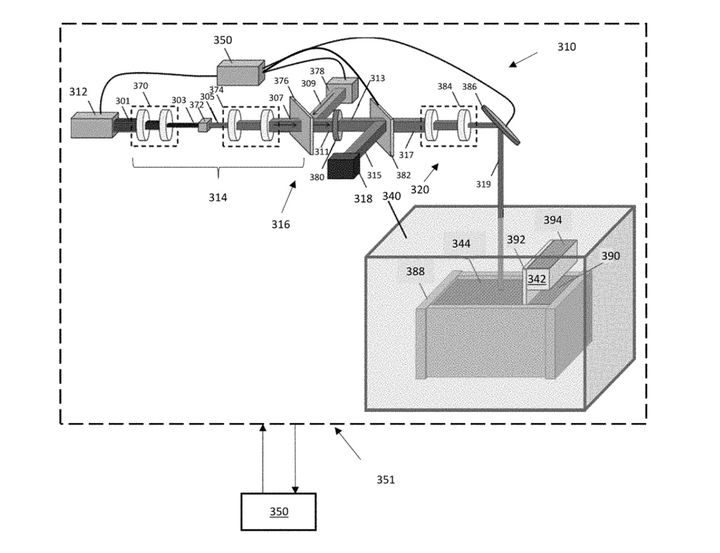

Patent 20170120332 describes an “energy patterning unit” that delivers “two dimensional patterned energy beams” to a “plurality of build chambers”. I get the impression there are multiple cells in this machine, each receiving very precisely engineered energy beams.

Patent 20170120530 talks about adjusting the optical beam size and intensity over different portions of the powder bed.

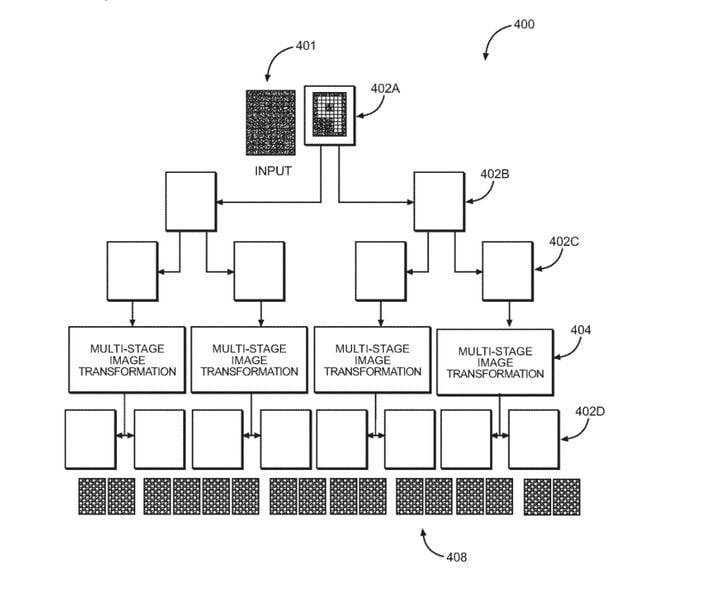

Finally, patent 20180326663 describes a strange “switchyard beam routing” system in which laser energy is cascaded through multi-stage transformation and steering units. This might be a method of using a single, powerful laser to be split into a large number of independently controllable beams. This may provide a high degree of parallel operation and thus speed up printing immensely.

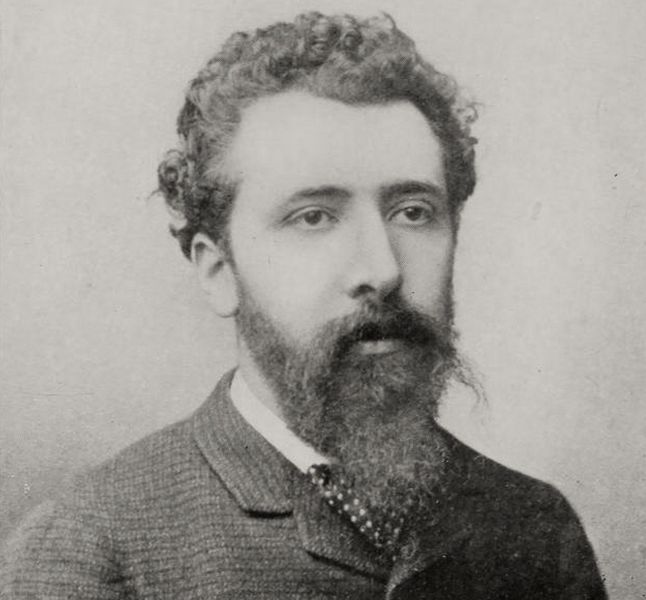

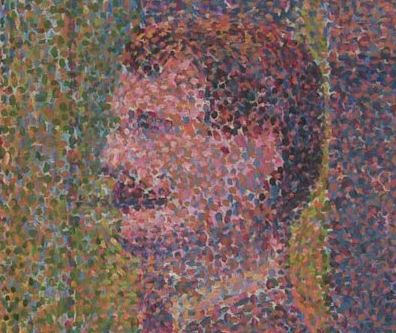

There’s one more clue to this mysterious company: its name. “Seurat” happens to be the name of a famous French artist, Georges Seurat. He’s responsible for the development of a new artistic style known as “pointillism”, or “chromoluminarism”. This style involves portraying an image by laying down a complex series of individual color points, that, when viewed from afar, mentally merge into a coherent picture. It’s like “dot matrix” painting. Here’s an example:

Could it be that Seurat Technologies is developing a metal PBF 3D printing system that does the same thing? Imagine a system that is able to simultaneously deliver independently controlled energy to small pixel-sized areas on a powder bed! That would be the ultimate in parallel 3D printing, as it would theoretically complete the entire layer in a single operation. Even SLM Solutions’ 12-laser device would be far slower to print objects.

But that’s my idle speculation based on reviewing some patents and putting two and three together. The real products hidden behind Seurat Technologies’ walls are yet to be revealed.

But when they eventually are revealed, they may cause a fuss among other metal 3D printer manufacturers.

Via Seurat Technologies (Hat tip to Benjamin)