Conformal cooling is not only a better way to cool injection molds for plastics, but it might allow hypersonic air travel.

Much of engineering is about putting heat in and taking heat out. Anyone who has studied heat engines knows that efficiency is determined by the Delta T between combustion temperatures and ambient, and this has driven designers to build hotter and hotter engines in everything from automobiles to jet aircraft.

This has driven the development of heat resistant materials such as nickel-based superalloys, but additive manufacturing is offering another way to achieve high heat transfer rates without very expensive materials: conformal cooling.

This build strategy allows everything from rocket engine nozzles to plastic injection molds to be optimized for heat transfer rates with high efficiency at low cost and promises to improve performance and lower unit costs in everything from space satellites to bottle caps.

Watch other episodes of End of the Line on engineering.com TV along with all of our other series.

Transcript of this week’s show:

To see any graphs, charts, graphics, images, and/or videos to which the transcript may be referring, watch the video at the source link.

A great deal of engineering is about making things that are hot. Whether you are injection molding plastics or building hypersonic aircraft, designing things that generate a lot of heat is a common element in multiple industries. Unfortunately, most materials used to make these things are less than optimally heat resistant.

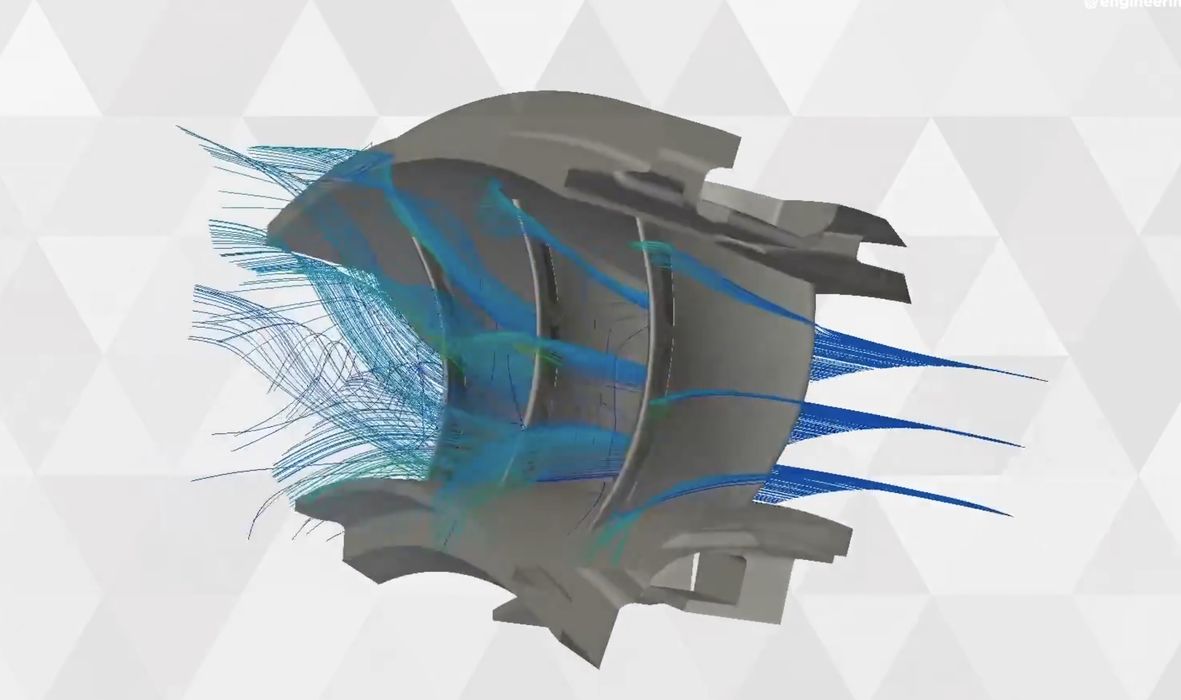

In a jet engine, for example, efficiency is everything, and the most efficient engines (as all first-year engineering students learn) operate with the highest Delta T between combustion temperature and ambient. To make the perfect jet engine, engineers need materials that can withstand temperatures that will melt conventional alloys—something which was known as far back as World War II, when German jet engine designers developed a clever workaround to avoid using high temperature superalloys called film cooling.

For exotic applications like jets, ceramic matrix composites are a popular material, but making your parts out of expensive, heat resistant materials is just one way to solve the problem. The other is active cooling, usually by pumping a cooling media underneath a hot surface to carry away damaging heat.

This has been standard practice for automotive engines for well over a century, and with the switch to electric vehicles, circulating liquid coolants, pumps and heat exchangers are still important technologies. The traditional challenge for design engineers, however, is that it’s very difficult to engineer cooling passages that are consistently just below the surface of hot parts that have complex shapes.

Read the rest of this story at ENGINEERING.com