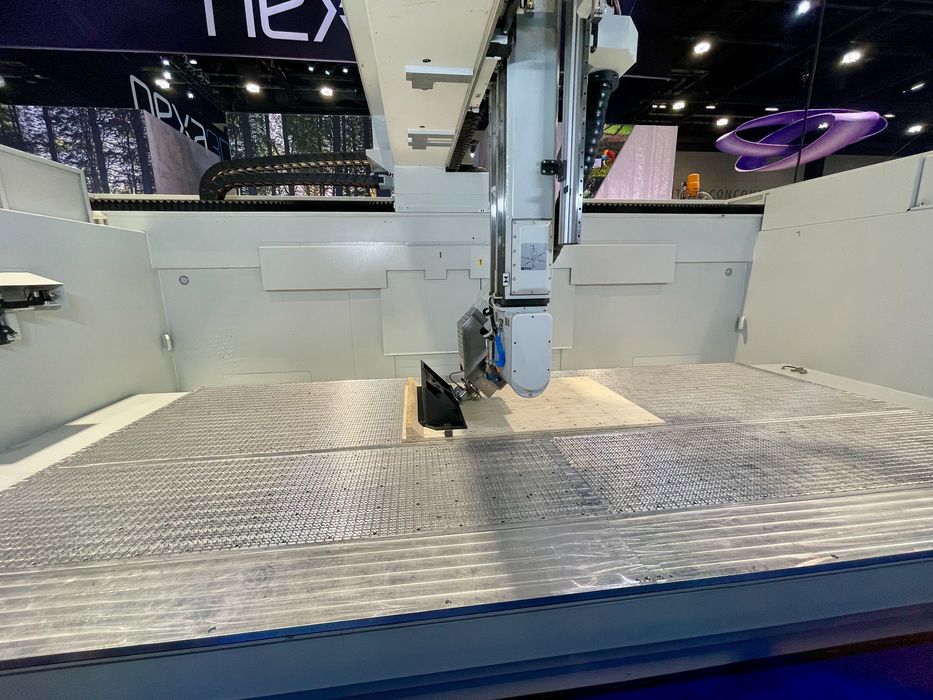

One of the largest 3D printers I’ve ever seen in person is the massive CMS Kreator.

This behemoth is the brainchild of CMS, a division of the Italian SCM Group. They’ve been producing machine tools since 1969, and recently, they’ve spiced things up a bit by delving into the realm of additive manufacturing.

Inside the “Small” Giant

The Kreator is no ordinary printer; it’s a large-scale hybrid 3D printer. This means it can do more than just print thermoplastic objects; it also boasts a CNC mill for polishing up those rough surfaces, as you’ll soon discover.

The version I saw was apparently the “small version”, as the company can make these devices to sizes requested by customers. As you can see in the image, it really isn’t that small.

CMS representatives tell us that this behemoth is typically used by aerospace and automotive industries to churn out gigantic molds for things like carbon fiber layups. Need a mold for a UAV wing? That’s a typical day’s work for the Kreator.

The Kreator’s Secret Sauce

Rather than using filament, this machine employs the more wallet-friendly pellet medium. It’s capable of handling PP, PC, ABS, and even high-temperature PEI pellets.

The prints it produces are quite coarse, with layers standing tall at around 2mm. This results in quicker print times – imagine if it were to use the standard 0.1mm layer height, it would take 20 times longer!

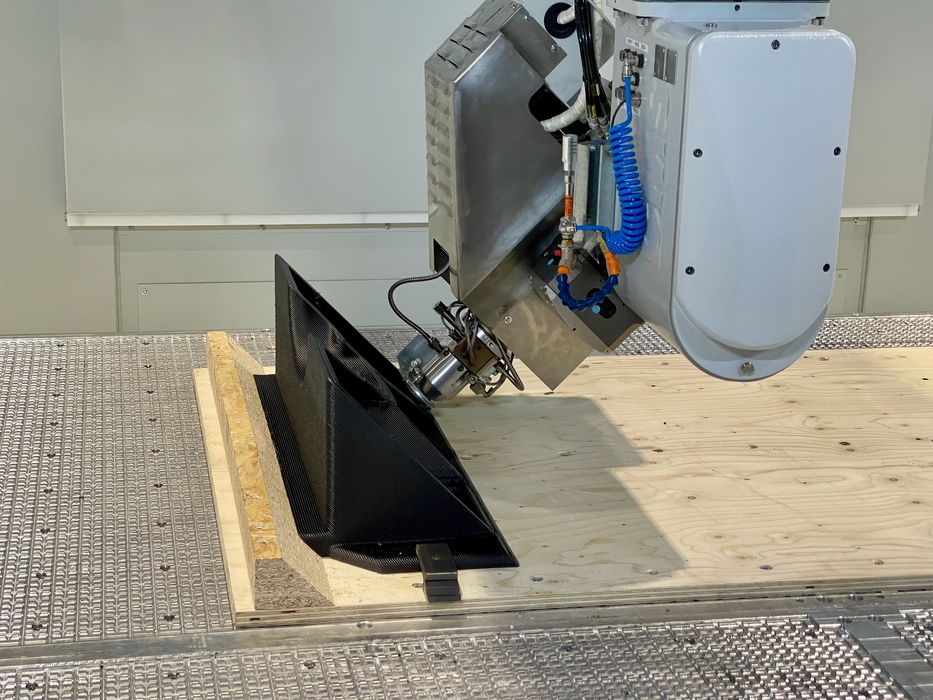

But don’t fret, the Kreator has a trick up its sleeve to remedy that rough finish. Its secret weapon? The CNC milling tool head. This wonder can whip the surface into a smooth finish after the print is done.

It’s possible you could just CNC mill the entire object, bypassing the 3D printing altogether, but the hybrid approach is more material-efficient, since only a thin layer of the surface is milled.

What’s more, the Kreator can double as a CNC mill if that’s what the customer needs. In that case, the 3D printing tool head gets a little break in its special garage atop the unit.

A Different Angle on Printing

The Kreator can print at various angles, much you’d see on a belt 3D printer. You might catch it working at a 45-degree angle, as seen in this image, but it’s also capable of taking on 45, 90, or even 0-degree angles, depending on the shape of the object being made.

Here’s an example of a print from this monstrous machine. Its size is immense, yet it took just about 6-7 hours to print on the Kreator, with an equivalent time for the CNC milling. That’s pretty speedy for such a large machine!

The Kreator is a marvel that would undoubtedly shine in specific manufacturing scenarios.

Via CMS