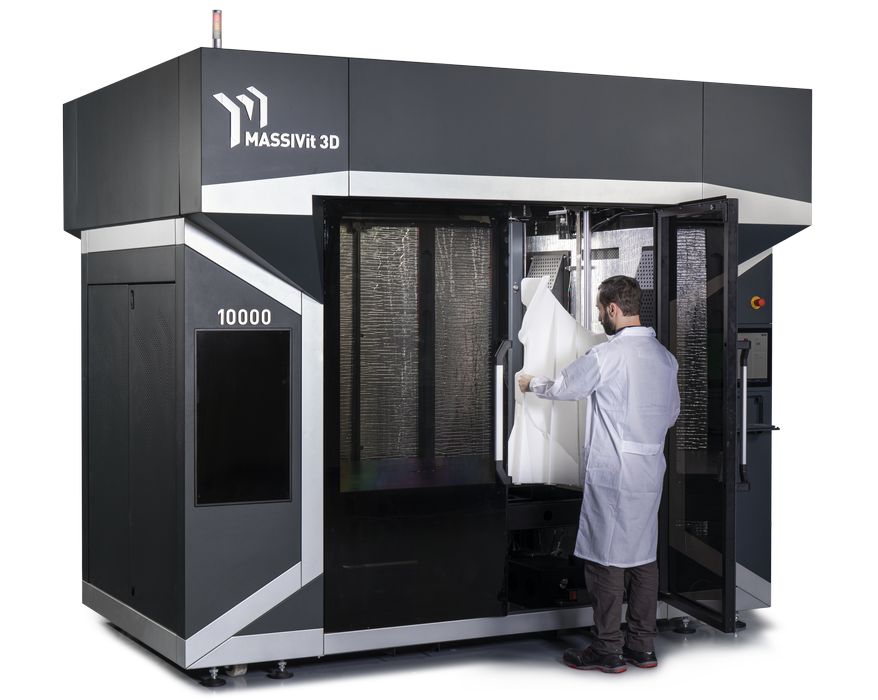

Massivit announced the official launch of a their biggest machine: the huge Massivit 10000 3D printer.

The Israeli company, founded in 2013, produces large-format 3D printers that use a unique process they call “GDP”, or “Gel Dispensing Printing”. They’ve created a gel that includes photoinitators, which cause the substance to solidify when exposed to UV light.

Their extruder deposits the gel within a chamber brilliantly lit with UV light, so it instantly solidifies and the print can proceed upwards. The interesting part is that the polymer used is not a thermoplastic as is most commonly used in 3D printing, but instead is a thermoset material that cannot be re-formed.

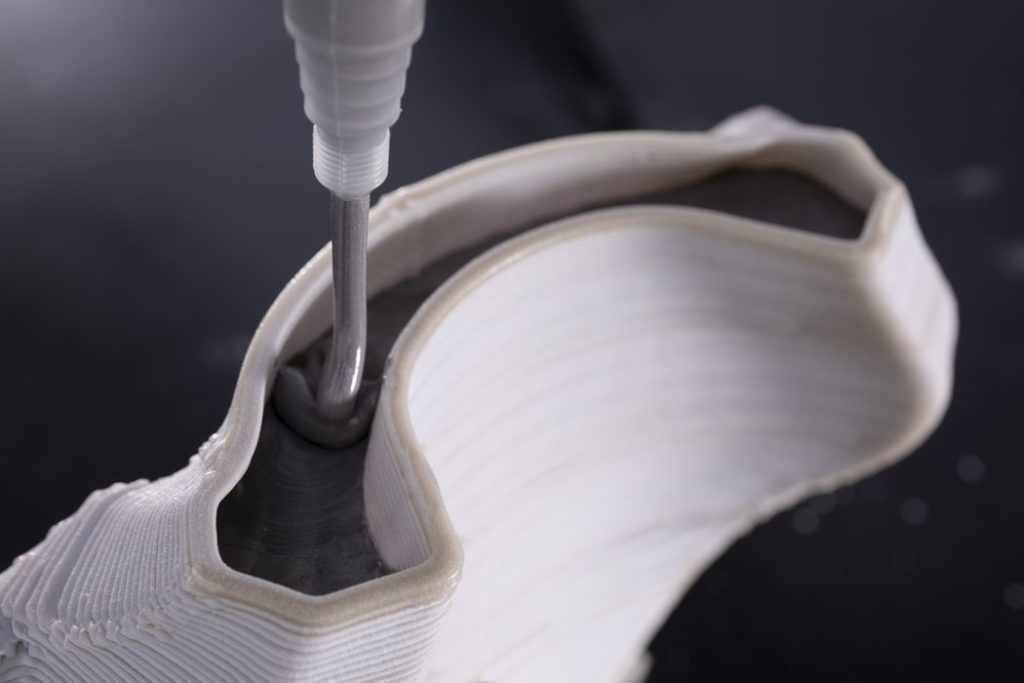

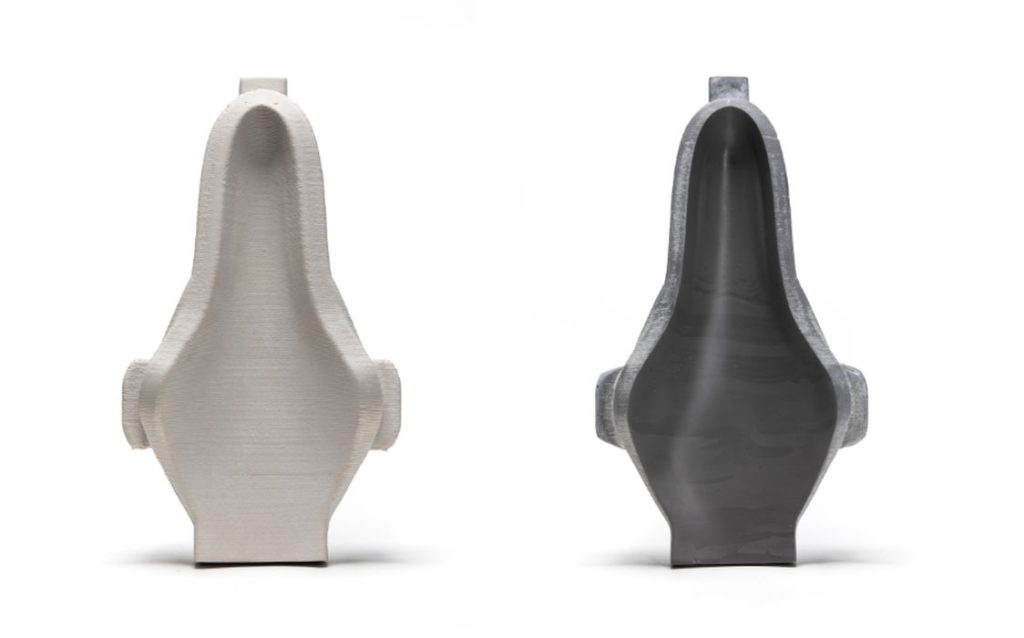

Their latest technology, “Cast-in-Motion”, offers a twist on this material. Instead of a thermoset material they use a soluble material. This means the prints produced can be dissolved entirely.

Why do this? It’s because they are not printing the end-use part, instead they are printing a mold for the part. The machine then fills the hollow interior of the print with a resin of choice that hardens. Finally, the 3D printed mold is dissolved to reveal the finished part. Evidently they have quite a variety of material resins for Cast-In-Motion.

For those companies producing cast parts, this technology is revolutionary: it apparently reduces the number of workflow steps from 19 to only four! In theory it should be possible to produce cast parts at a very good cost. Massivit explains:

“Massivit 3D’s Cast-In-Motion technology enables composites fabricators to shorten their tooling workflows from the traditional 19 steps down to 4 steps. It eliminates the need to produce an initial plug or master by directly printing and casting the mold using ultra-fast additive manufacturing combined with industrial-grade casting materials. This cutting edge process shortens tooling time by 80% and offers a myriad of business benefits including a reduction of manual labor, a 90% decrease in labor-associated costs, a reduction of associated inventory and transportation, and a significant decrease in waste of expensive materials.”

The other advantage is that the 3D printing approach allows parts to have any conceivable geometry, which is different from traditional casting that has more constraints.

Massivit explains:

“The Massivit 10000 brings to market the first 3D printed isotropic mold for composites manufacturing. As opposed to existing thermoplastic additive tooling systems, the Massivit 10000 utilizes high-performance thermoset-based materials to produce a single, uniform cast that results in a true isotropic mold. In addition, it provides molders with casting materials that have highly predictable mechanical and thermal properties, a low Coefficient of Thermal Expansion, and a high Heat Deflection Temperature.”

About a year ago the company announced the Massivit 5000 device, which uses thermoset materials. Later in 2021 they announced the Cast-In-Motion technology and the Massivit 10000, which was to enter the market later.

That time has arrived, and Massivit will show the machine to the public at an event in early May. Customer shipments are to begin in the second half of the year.

Massivit said they have received an amazing 17 pre-orders for the unusual machine thus far, suggesting considerable interest in the unusual casting approach.

Via Massivit