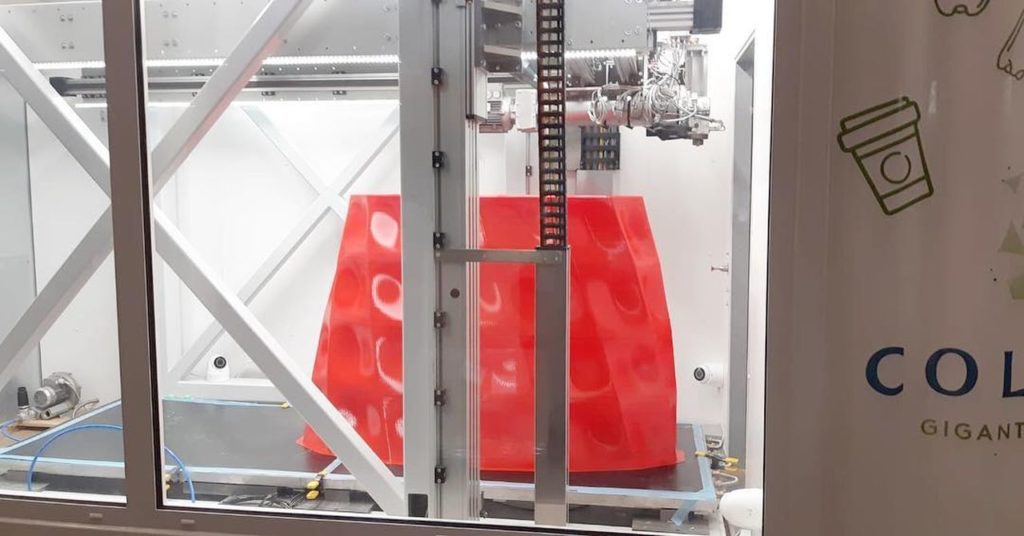

Today I’m looking at Colossus, a manufacturer of very large format 3D printers.

The company’s tag line is “Gigantic 3D Printing”, and they’re definitely not kidding. Their several 3D printers are all massive in print volume.

Launched in 2017, the Belgian company intended on using recycled materials to produce large thermoplastic objects in a responsible manner.

Currently the company offers three 3D printers:

Colossus Mark II

This is the second generation machine from the company, and it offers a massive 2700 x 1250 x 1500 mm build volume. The Mark II is unique in that it is designed for transport, and can be more easily moved to a remote location for on-site production.

Colossus Mark II Static

The Mark II Static is essentially the same as the Mark II, but is designed for permanent installation. However, because the machine is not intended for transport, there are fewer dimensional constraints and thus the company can provide larger build volumes on request.

Colossus XS

The latest device from the company offers a 1600 x 1200 x 1300 mm build volume, but also has a faster print rate of up to 200mm per second. This machine is to be available for order this December.

Robotic Systems

While their main line of 3D printers use a standard cartesian motion system, Colossus also offers the possibility of using their print technology in robotic environments. They can develop custom solutions for specific projects requiring robotic movements.

Fused Granulate Fabrication

All Colossus machines use the FGF process, or “Fused Granulate Fabrication”. This is different from the standard FFF approach, where the material is in filament form of a specific diameter. Instead, FGF uses pellets as input.

There’s a good reason for this when using very large build volumes: cost. Filament is made from raw pellets, and by definition must cost more than the original pellets. By allowing the machine to use pellets directly, material costs are substantially reduced. This is quite important for the massive 3D prints produced in Colossus equipment.

Colossus offers quite a variety of materials for their massive 3D printers, including:

- Recycled PETg

- Recycled PETg Carbon (composite material)

- Recycled PETg Glassfibre (composite material)

- Recycled PETg Stone (composite material)

- Recycled PP

- PP

- PPL

- PE

- Recycled PLA

- Recycled PLA Wood (composite material)

- Recycled PLA Stone (composite material)

- Recycled PLA Bronze (composite material)

- Recycled PLA Hemp (composite material)

- PLA

- PC

- Durabio PC (bio-based)

- TPU

- TPC

All materials can be obtained in custom colors, as Colossus offers the ability to select from a wide range of masterbatches.

The company’s latest material is LW PLA from colorFabb, which is a highly unusual material. As the material is heated, it begins to foam by developing tiny bubbles. These occupy space within the extrusion and result in extremely lightweight 3D prints.

This could be a very important property for materials used in very large prints. It’s easy to say there’s a big print volume, but a lot harder to lift out the massive weight of a huge print when done. LW PLA may solve that issue for some Colossus clients.

For applications requiring very large 3D prints at relatively low cost, Colossus equipment could be a good option.

Via Colossus