It is certainly a milestone if you’ve purchased the largest 3D printer on the market, but what if you bought another?

That’s precisely what has happened at Tooling & Equipment International, a foundry based in Michigan. The company produces a variety of metal products including blowtubes, tooling, automation systems and casted prototypes. This video shows an example of the complex metal casts they can produce:

That last category is accomplished partly with the use of voxeljet 3D printing equipment. Munich-based voxeljet is known for producing large-scale sand-based 3D printers that can produce molds for casting metal parts.

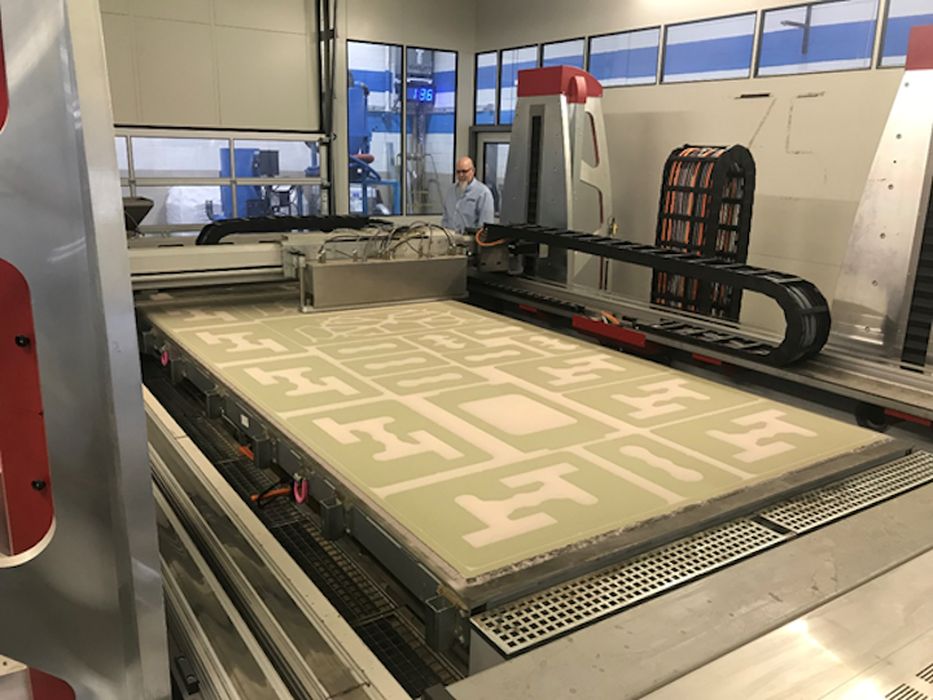

voxeljet’s process is quite scalable, and the company has leveraged that capability by producing some of the very largest stock 3D printers on the market. The largest device in their catalog is the truly massive VX4000, which sports a build volume measured in meters: 4 x 2 x 1. To put that in perspective, that’s about the same build volume as 1,000 typical desktop 3D printers!

Note there are 3D printers of greater build volume, most notably in the construction sector. However, many of those machines are custom-built for specific applications. The VX4000 is certainly the largest off-the-shelf stock 3D printer from non-construction 3D printer manufacturers.

The VX4000 is used to produce massive sand molds for casting complex metal parts that would otherwise be impossible or extraordinary difficult to produce using conventional manufacturing techniques.

Tooling & Equipment International (TEI) owns and operates a VX4000 to produce these massive metal parts, but now they are buying a second machine.

voxeljet said:

“The engineering expert decided to invest in the second VX4000 3D printer to further expand its already existing capacities for additive manufacturing and quickly and economically realize technically demanding projects for prototyping inquiries as well as production orders. The 3D printer will be installed at TEI’s Livonia facility in Livonia, Michigan.”

TEI President Oliver Johnson explained further:

“At our facility we cover the full workflow, from printing to casting to heat treatment and machining. With the second VX4000 in house, we are able to further capitalize on the advantages 3D sand printing has to offer to metal casting. By eliminating the need for tooling and thanks to the large build volume of the 3D printer we can reduce delivery times drastically, which in turn greatly benefits our customers, whether it’s the automotive or aerospace industry. In addition to that, we can produce parts that cannot be made conventionally, such as light-weight components and topology optimized parts.”

This acquisition tells me several things.

First, it’s clear that TEI is doing very well. But more importantly, it tells us that there are an increasing number of part requestors that are taking advantage of this technology.

This is important because it’s literally been decades where 3D printer manufacturers have tried to explain the new technology to part manufacturers through a variety of approaches. Sometimes they are successful (aerospace), but many times are not, as many manufacturers are reluctant to change.

Could this sale be an indicator that the barriers to adoption of additive manufacturing are coming down in more industries? It’s only one sale, but it’s a large sale, in more ways than one.

Via voxeljet