SPONSORED CONTENT

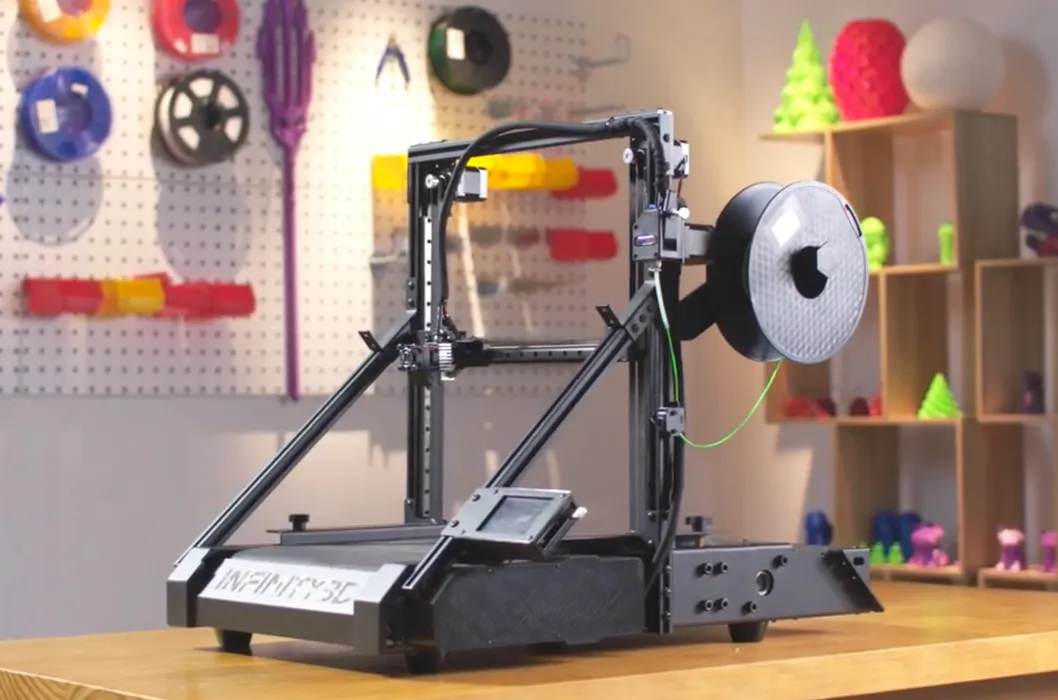

I haven’t seen this before: a 3D printer that uses a moving belt — except when it doesn’t.

This new machine makes use of the latest trend in desktop 3D printing: a belt driven print surface. This style of 3D printing involves tilting the hot end to a 45 degree angle and printing on a continuously moving surface, as the belt slowly rotates.

That configuration allows 3D printing to have no theoretical limit to the size of the Z-axis: the belt simply keeps turning as long as necessary. In theory one could 3D print an infinitely long part, hence the name of this device.

In practical terms, you cannot 3D print an infinitely long object as you’re limited by the material supplied and by the length of the support structure needed to hold up the part as it comes off the moving belt.

Nevertheless, there are now several 3D printers on the market that offer belt capability, and quite large objects have been produced.

However, the Infinity3D 3D printer is very different. Yes, it appears to be a belt 3D printer, until you switch it back into normal 3D printer mode!

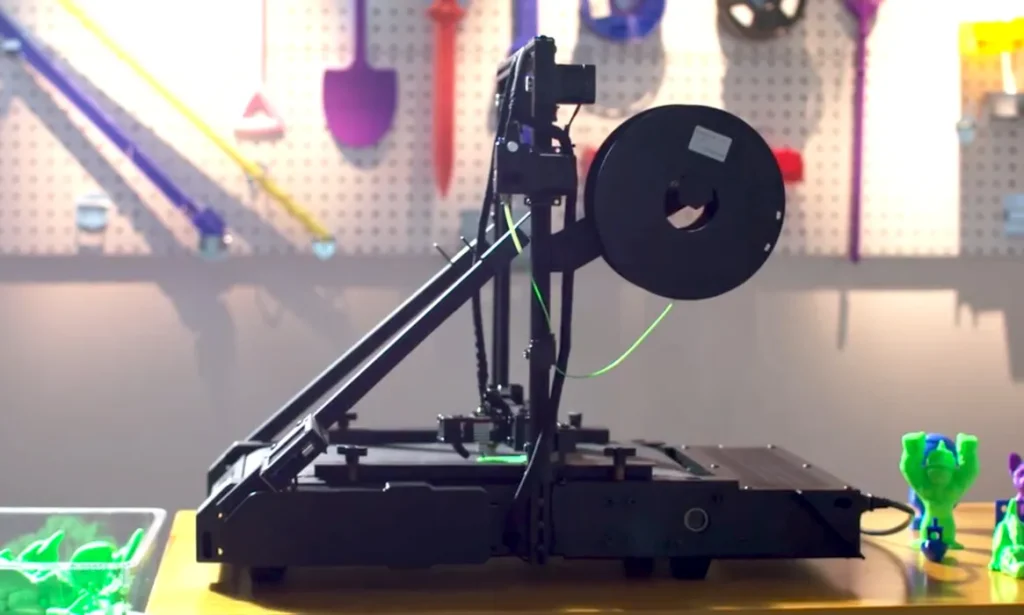

The device is designed to tilt the gantry. It can be oriented to a 45 degree angle for belt operations, but later tilted up to a 90 degree angle where it can undertake “normal” 3D print jobs that don’t require a lengthy build volume.

The Infinity3D is like two 3D printers in one: it’s a belt 3D printer and also a traditional 3D printer. The operator needs only a simple move to change modes, and of course print jobs must be sliced with different parameters. Here is an animation of how the change works:

There are then three ways this device could be used:

- As a traditional 3D printer to print tall objects

- As a belt 3D printer to print very long objects

- As a belt 3D printer to continuously 3D print smaller objects without limit

That last point is of most interest to me, as it effectively transforms the 3D printer into a kind of “factory” that can produce small volumes of objects. For example, if an object takes 30 minutes to print, then after one day of operations, 48 objects would have been produced. Or 336 over a weeks time, if the operator was able to keep supplying the Infinity3D with filament.

Infinity3D Specifications

The specifications for this device are a little unusual, because it’s really like two 3D printers.

When in 90 degree mode, the build volume is a very generous 250 x 220 x 323 mm. This is larger than found on typical desktop 3D printers, particularly in the Z-axis. But when operating in belt mode, the build volume changes to 250 x 215 x infinity. Yes, “infinity” because there is no theoretical limit.

The Infinity3D includes a 3.5 inch color touch screen for operations.

The frame of the Infinity3D is made entirely from metal, which should provide good rigidity, particularly on tall 3D prints when in 90 degree mode. The motion system is made with linear rails for smooth operation.

The belt does not use linear rails, but instead includes a woven fiber material designed to ensure prints stick very well during printing — but also release them automatically as the belt turns around. Usually the belt 3D printer operator will place a bucket at the end of the rollers to catch completed prints when in “factory” mode.

Like many 3D printers, the Infinity3D includes a filament-out sensor that will automatically pause operations when it can’t find any filament. This allows the operator to replenish the spool and then resume operations. Similarly, the Infinity3D will also detect when power fails and gracefully shut down, able to resume operations when power is restored.

These are always valuable features, but they are particularly important for a belt 3D printer that might be operating in factory mode and often run out of material.

I’m quite happy that the Infinity3D includes TMC2209 stepper drivers, which provide for near-silent operation. These have become more popular in recent months, and this ensures the Infinty3D is a quiet device.

Job preparation is done using a modified version of Ultimaker Cura, which is able to handle the peculiar dual modes of this device. There are print profiles for both modes, and is easy to use.

The hot end on the Infinity3D is the well-proven E3D-Online V6 unit, which has been used on many other machines. It’s able to hit 280C, enabling the Infinity3D operator to 3D print a wider variety of materials. To complement the hot end, the print bed can be heated up to 110C, again assisting with 3D printing of engineering materials.

Infinity3D Pricing and Availability

The Infinity3D is now available for order via their Kickstarter campaign. Initial early bird pricing for this unusual hybrid machine starts at only US$499, quite a low price for a belt 3D printer and certainly a great deal when you realize you’re actually getting two machines in one. The expected retail price will be approximately US$800, so this is a significant discount. Also offered are a spare belt for US199 and a roller extension to handle longer belt prints for US$100.

If you’re interested in belt 3D printing but also want to 3D print the “normal way”, the Infinity3D printer might be worth looking at.

Via Kickstarter