SPONSORED CONTENT

The Geeetech Mizar S has some unusual features for a low-cost desktop 3D printer.

Geeetech, which has one of the most interesting brand names in the business, has been producing desktop 3D printers for over ten years. Currently they offer an amazing 15 different FFF devices, and one MSLA resin 3D printer. Today we’re looking at their latest FFF device, the Geeetech Mizar S.

This single-extrusion machine has an open gantry format, similar to other machines of this class. The Mizar S is a member of their Mizar series, of which there is one other member, the Mizar DIY 3D printer. The Mizar S is a more powerful machine equipped with more advanced features.

The Mizar S has a rather large build volume of 255 x 255 x 260 mm, which offers the ability to 3D print objects much larger than the more typical 200 x 200 x 200 mm volume found on most other devices.

The Mizar S frame is built from sturdy aluminum extrusions, and should provide a robust platform for the motion system.

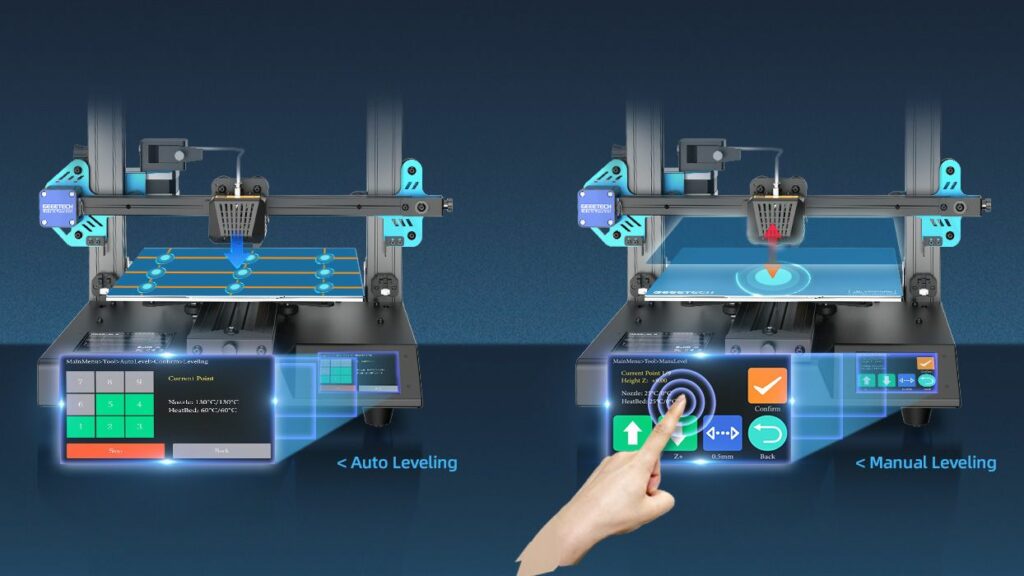

The main feature of the Mizar S is a sophisticated automatic leveling system that can be triggered by one touch; there is no manual effort required. The system includes an on-board sensor that is always ready, as opposed to some other devices that require a special add-on sensor for leveling.

The leveling system automatically determines the contour of the active build plate, and then adjusts the first layer of printing to ensure a consistent distance from the extruder is maintained. This ensures that the first layer will stick very well and could avoid some print failures. You will, however, have to set the base Z-gap distance between the nozzle and print plate, as is done on all desktop FFF 3D printers.

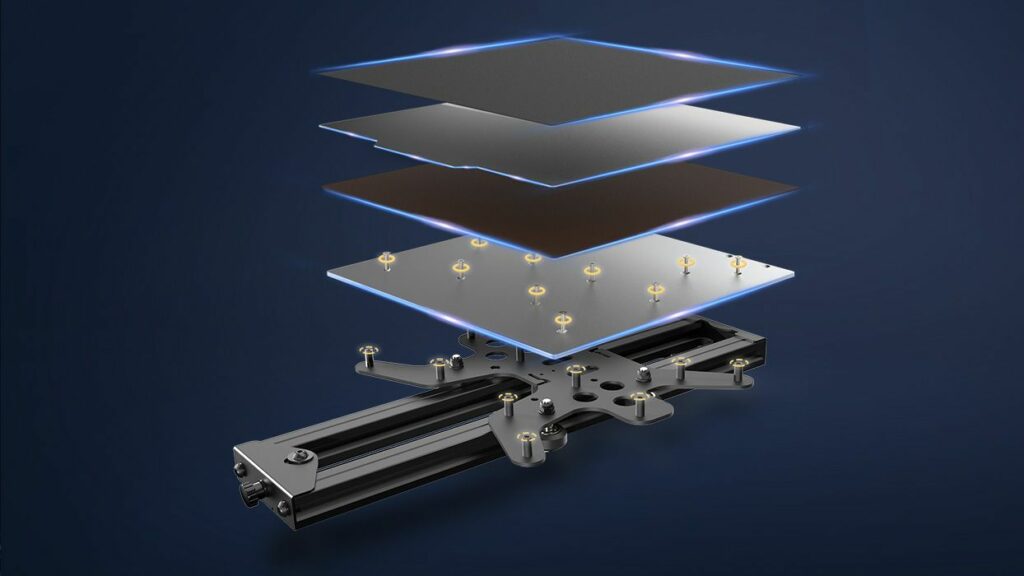

The build plate of the Mizar S is both familiar and different. It is a magnetically attached, flexible steel plate that is used very often by other desktop 3D printers for each print removal: you simply twist the plate and most prints pop off. However, while most systems use a PEI coating for the adhesive coating on the print plate, the Mizar S uses a mylar film.

Mylar is a form of PET, and should adhere to the most commonly used 3D printing materials.

The build plate can be heated to 110C, enabling the machine to handle challenging materials like ABS.

Geeetech has equipped the Mizar S with a powerful 32-bit control board that should be able to keep up with the most complex 3D prints imaginable. The system also includes the highly desirable TMC2208 silent stepper drivers, which essentially eliminates noise from the motion system and renders the device so quiet it could be used in an office. Geeetech said the noise level does not exceed 50dB, which is extremely quiet.

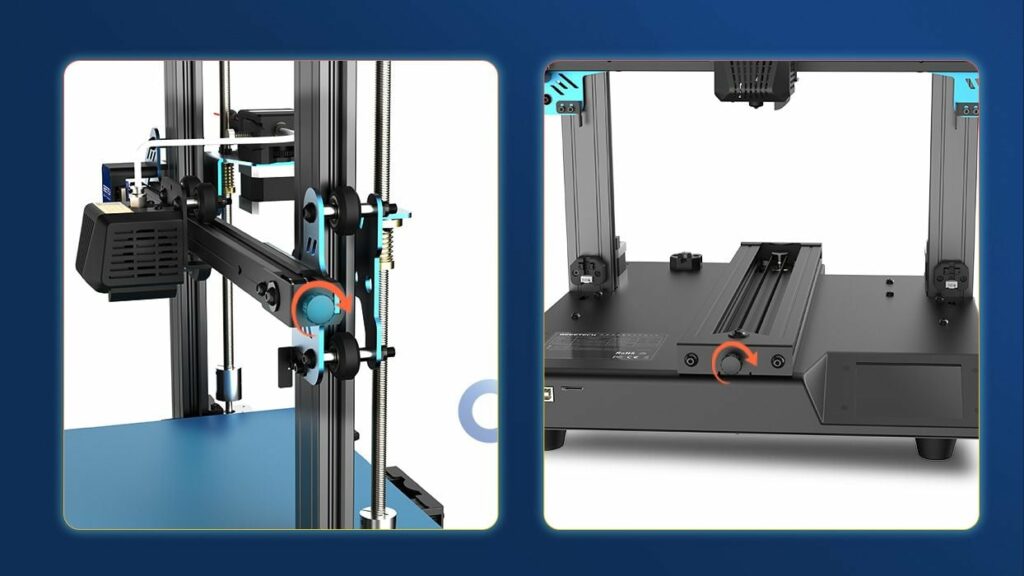

The single extruder on the Mizar S uses a dual-toothed gear configuration. This arrangement “bites” the filament on two sides and ensures there will be no filament slippage. This is particularly useful when printing flexible TPU material that often fails on other machines.

The extruder and hot end are capable of handling a variety of materials, including PLA, PETG, ABS, and TPU polymers.

An unusual feature on the Mizar S is a lighting system mounted on the toolhead. The LED light is RGB controllable, and can display in white or other color modes. This is especially useful if you have a webcam monitoring the print, because the light ensures the camera can always see the current printing activity.

Two common failure scenarios are avoided with the Mizar S.

There is a filament-out sensor that identifies when the end of the filament is encountered. A detection causes the Mizar S to pause and wait for the operator to change the material spool when you’ve run out. This avoids partial print failures, which are both annoying and expensive, particularly for large print jobs where you don’t know how much of the spool will be consumed.

The Mizar S also includes a power failure process. Should the power fail, the system records the exact position in the current job’s GCODE. Then, when power is restored, the operator is given the option to resume the print. If so, the Mizar S heats up the hot end and continues printing exactly where it left off.

One very useful feature on the Mizar S is handy knobs for adjusting belt tension. In earlier machines belt adjustments were a difficult affair involving wrenches. Now a simple twist of the adjustment knobs on the Mizar S can quickly re-tension both the X and Y axes.

Control of the Mizar S is performed from a 3.5” color touchscreen at the front of the machine. The screen is angled appropriately for operators using the machine at standard desk height.

Software for the Mizar S is Ultimaker Cura, which ensures the most advanced slicing features are available for the machine. Geeetech provides a downloadable Ultimaker Cura profile for the Mizar S, which is very easy to install.

The Mizar S is basically pre-assembled, but split into two main parts for shipping purposes. Buyers will have to mount the gantry on the base and connect a few cables, which is easy and quick to complete.

Pricing of the Mizar S is quite aggressive, with the list price at US$469. However, until November of this year the machine will be available from the Geeetech online store for only US$375, which is quite a good price for a machine with these features.

Via Geeetech

I’ve been using the Mizar S for a year now , I’m very pleased with it , good print and so far trouble free