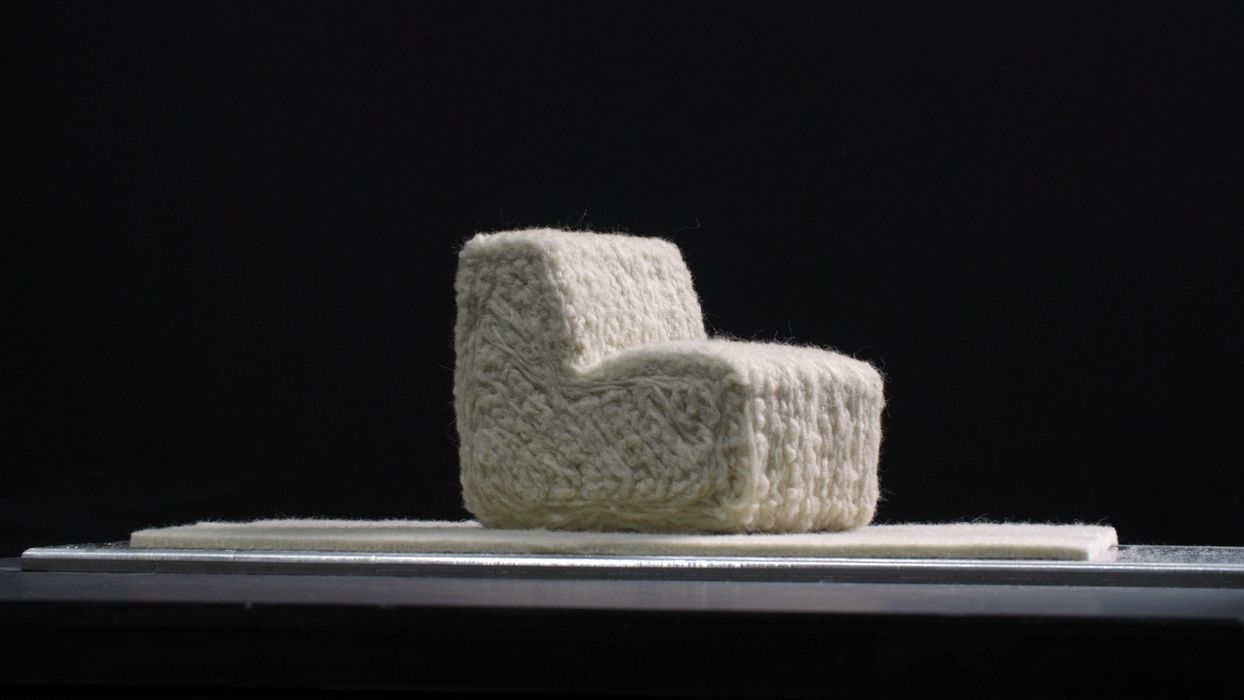

The FLOCKS Wobot is a wool 3D printer.

I’ve seen many different materials used for 3D printing in the 17 years I’ve been involved with the technology, but never wool.

Wool has for centuries been used to produce 2D products, mostly clothing. Here, however, there is a way to produce 3D objects made from wool.

The project to produce the Wobot cobot was undertaken by designer Christien Meindertsma and Tools for Technology, and was shown at two exhibitions this year in Europe.

The solution is robotic, as you can see in this image. It’s not clear exactly how this works, but it seems that the robot uses a thick input cord of wool material, and somehow “knits” it into the desired 3D geometry.

The group is working on two solutions that may eventually be commercialized. One is to produce solid blocks of wool material that can be cut later into required shapes.

The second solution is of more interest to us: it’s a way to 3D print the shapes directly, as you can see in the images.

Why do this? It turns out there is a fantastic amount of wool waste. Consider the production of clothing, where there are countless offcuts as 2D shapes are cut. These normally go to the landfill where they eventually decay.

However, it would be possible — and has been proven by the team — that it’s possible to mix colored offcuts with fresh natural wool to create specific colors in the printable wool material.

The output from this device can be used in many ways. For example, a wool shape could substitute for foam packaging. If done at scale, this could reduce the use of fossil-based polymers and replace them with completely biodegradable wool material.

The wool prints also offer good acoustic properties: they can be used as sound absorbing artifacts for noisy environments, as the wool is near perfect for slurping up nearby sound waves.

However, commercializations of this promising technology will be challenging because it will require convincing industries to change their processes that have been in use for decades. It may be that increasing focus on microplastic pollution may direct some interest towards wool-based solutions.

Via Christien Meindertsma (Hat tip to Benjamin)