Flashforge announced a new desktop 3D printer, the Adventurer 4.

Flashforge is one of the oldest desktop 3D printer manufacturers, having launched well over ten years ago. Back then the company marketed relatively rudimentary 3D printers as compared to today’s models. But over the intervening years, Flashforge has gradually enhanced each successive product, and today offers around twenty devices using multiple 3D printing processes.

The latest model from the company is the new Adventurer 4, which follows on from the previous Adventurer 3.

The Adventurer 4, unlike many desktop 3D printers, is a fully enclosed unit. This provides several advantages, including reduced operational noise, but most importantly capturing heat and eliminating drafts that could affect print quality.

Perhaps the most notable change from the Adventurer 3 is that the Adventurer 4 is a much larger device. The build chamber is a huge 220 x 200 x 250 mm, whereas the Adventurer 3 is only 150 x 150 x 150 mm.

Beyond build volume, there are a number of other terrific features on the Adventurer 4.

Adventurer 4 Nozzles

The most interested feature on the Adventurer 4 is a quick-swap hot end system. The “buckle” mechanism allows an operator to change the hot end in apparently only three seconds, and that has to be one of the fastest nozzle-swapping systems I’ve seen.

While the default hot end for the Adventurer 4 includes a PLA-capable 240C 0.4mm nozzle, two additional hot ends are also offered:

A 240C 0.3mm nozzle suitable for high-precision work

A 265 0.6mm nozzle suitable for faster large-sized prints and also for use with engineering materials.

The 240C hot ends are fine for PLA, but might struggle to print materials requiring higher temperatures. That’s why Flashforge has included a 265C hot end. They said this hot end is usable for materials such as ABS, PC, PETG, PLA-CF and PETG-CF — and of course, regular PLA. It is possible the Adventurer 4 may also be able to 3D print nylon material, but I’d have to give it a try.

This hot end changes the utility of the Adventurer 4 in a big way: it can produce objects in engineering materials and thus produce parts for many more real-life applications. Machine designers requiring components can now consider using the Adventurer 4.

Adventurer 4 Build Platform

Flashforge has done some very interesting moves for the build platform on the Adventurer 4.

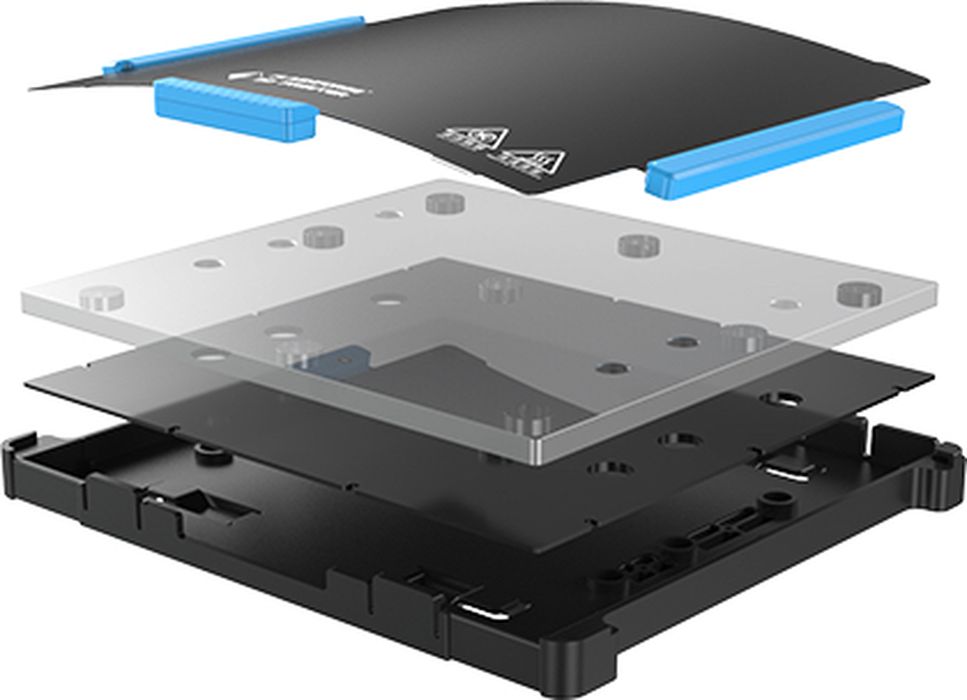

The horizontal frame is made from high-precision CNC-cut metal. This is quite unlike the designs of other desktop 3D printers that often have a collection of parts bolted together. While those systems might wobble, there is no chance the Adventurer 4 will do so with its very solid base.

Under the print surface, Flashforge has planted a massive 8mm aluminum plate to ensure rigidity and flatness. They say the plate’s surface diverges by only 0.15mm, but even that is handled by their automated 9-point leveling system.

On top of the aluminum plate is a magnetically-attached, flexible spring-steel build surface that is coated with an appropriate adhesion solution. This makes it trivial to remove prints by simply twisting the removable surface.

The build surface can also be heated to 110C, which is ideal for most engineering materials.

Adventurer 4 Safety

There are several safety features on the Adventurer 4, and that’s something I like to see, as many 3D printer manufacturers seem to have a lower priority for operator safety. Not so with the Flashforge Adventurer 4.

The main safety feature is the enclosed chamber, which prevents accidental encounters with moving or hot parts. But Flashforge has gone past that by including a HEPA-13 filtration system in the build chamber. This removes most of the nanoparticles and VOCs from the airflow, and thus makes the Adventurer 4 suitable for use in an office setting.

Adventurer 4 Control

The Adventurer 4 includes some interesting control features.

One is the on board webcam. While many 3D printers these days include a webcam, the Adventurer 4’s can be controlled in a different way. You can set it to automatically capture a time-lapse of the 3D print, something you can’t normally do on typical onboard webcams.

They’ve also managed to find a way to provide a door to a hidden spool holder. This means the 3D printer will not appear with a spool, unlike almost every other 3D printer. The spool chamber capacity is said to fit up to 1kg spools.

As is becoming standard in most systems these days, the Adventurer 4 includes a filament-out detection sensor, which allows the machine to pause and resume later when more filament is provided.

The Adventurer 4 includes a WiFi connection that allows remote control of the 3D printer. The onboard webcam will certainly be helpful in this regard.

Finally, the Adventurer 4 can be managed by FlashPrint, Flashforge’s new 3D print management system. This software is apparently able to control multiple devices as seen in their promotional video:

Perhaps the best feature of the Adventurer 4 is its rather low price: US$799. This is a very good price for a machine that is fully enclosed and includes the features described above.

Via Flashforge