Interesting research from the Technical University of Denmark shows how to break into a new industry.

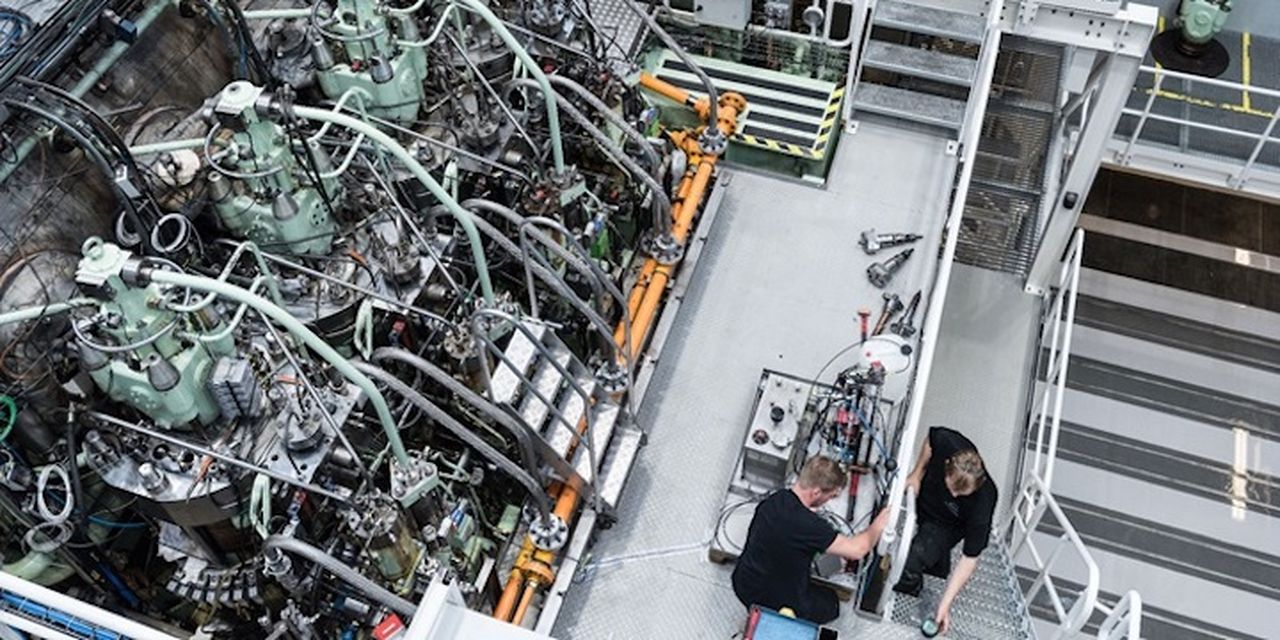

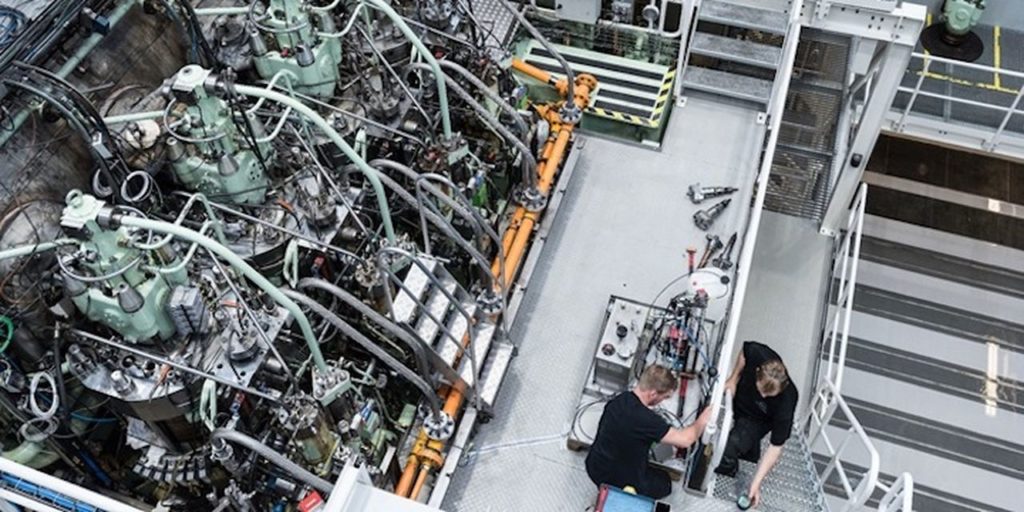

The work was undertaken by a partnership between the University and MAN Energy Solutions, who wondered whether it was possible to 3D print a better injection nozzle for large marine engines.

DTU Mechanical Engineering Postdoc Thomas Dahmen performed a detailed qualify deployment function analysis of the part with respect to 3D printed solutions. Dahmen said:

“By applying the model and combining it with technical insight into both 3D printing methods and fuel injection, I have created a modular kit of how 3D-printed nozzles can be designed to increase engine performance and product lifetime.”

The study also contrasted the two major metal 3D printing processes, binder jetting and LPBF, to identify the advantages and disadvantages of each.

DTU explained:

“The improvement of the injection nozzle was based on the fact that a better fuel flow could be achieved with a slightly different—and more curved—design. In this way, the new nozzle design contributes to improved engine combustion. Initial trials also suggest that the nozzle could potentially help reduce NOx emissions from the engine, but further studies will be required to demonstrate such an effect.”

This is important because if one could make marine engines even slightly more efficient, it could prevent massive quantities of emissions from entering the atmosphere, simply by swapping an engine part.

MAN Energy Solution’s Mechanical Engineer Peter Hagan said:

“The test went well, and we look forward to doing a long-run test next. Thomas’ thorough investigation has given us a fantastic basis for moving forward with 3D printing of metal components for marine engines. I’m quite sure we’ll see them in real engines soon.”

This is where you can see the importance of this type of study.

In general, businesses tend to not want change. If something works, then don’t change anything! That mentality has long prevented the adoption of 3D print technology in many industries, and it’s only been through tedious persuasion over the course of many years that 3D printer manufactures have convinced a few industries to take up the tech.

Here we have institutional researchers partnering with industry to pioneer a very complex application of 3D printing technology. The result was successful, and it seems that there is now a base of proven knowledge that could break down the barriers to use of these advanced parts.

If only every industry could receive this benefit.