Charles R. Goulding and Preeti Sulibhavi look at the potential for increased use of 3D printing in the aerospace industry.

The Farnborough Airshow took place in England from July 18th through July 22nd, 2022. Industry themes included space exploration, defense, sustainability, innovation, the future of flight and workforce changes across the industry. The show has resumed after being previously canceled due to Covid-19.

In keeping with the current crisis in Ukraine, Russia was barred from attending this year’s show. The attendance was still expected to be decent despite the sweltering heat wave gripping the country.

Boeing is experiencing a huge increase in demand.

At the show, a massive deal was announced between Boeing and Delta Airlines for over 100 of the 737 aircraft. In an order worth over $15 billion from Delta Airlines and Lufthansa, Boeing is witnessing a demand resurgence after Covid-19 restrictions are being lifted. Boeing’s only constraints are supply chain challenges.

Boeing’s Chief Executive Officer, Dave Calhoun, said in an article published in the Financial Times on July 19th, 2022, that “we all have to put two-and-a-half years in perspective and what we’ve done as a leadership team to get ahead of each and every one of our big issues.”

Exhibits at the Farnborough Airshow showed the 3D printing industry can benefit and learn from.

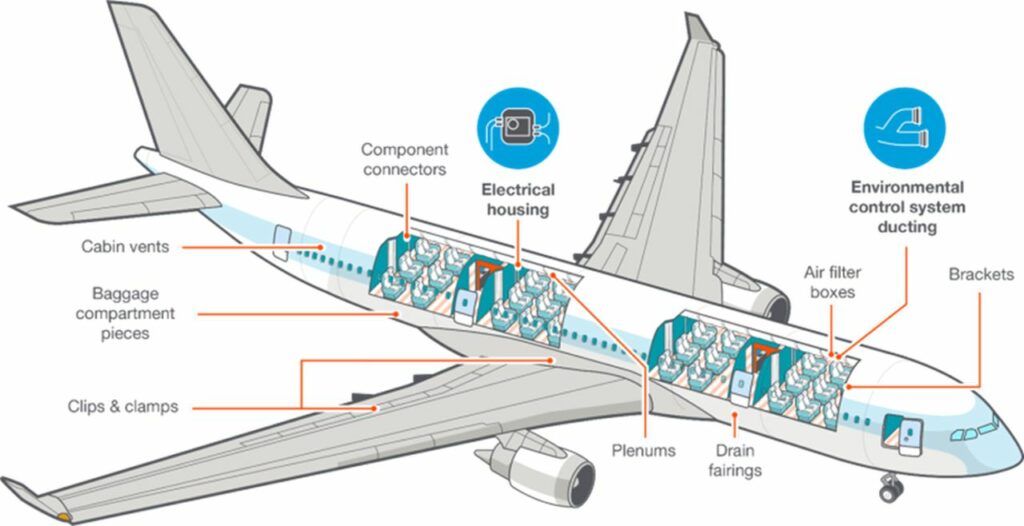

Boeing is competing with Airbus for market share and customers. Losing revenues due to Covid-19, the airline industry is experiencing unprecedented demand. To overcome supply chain issues and position itself as the leading global aviation giant, Boeing can utilize 3D printing to overcome supply chain obstacles. 3D printing can be used for fabricating interior aircraft parts quite effectively.

Aircraft engines have been a particular supply chain issue. Airbus has 26 “gliders,” which are complete aircraft but sitting in storage without engines.

Greg Hayes, Chief Executive Officer (CEO) of Raytheon/Pratt Whitney, in an interview at the show said that the industry has shifted from unprecedented demand shock in 2020 to unprecedented supply shock today.

The Farnborough Air Show had several other developments that the 3D printing industry can take note of:

Day 1: Direct Air Carbon Capture & Storage (DACCS) system – this is a highly advanced technology that allows up to 90% of CO2 emissions to be filtered and removed from the air using fans and absorbers in a carbon-neutral facility powered by zero-emission energy sources. Post-filtering, it is safely and permanently stored in depleted underground oil and gas fields or deep salt formations. DACCS enables the aerospace industry to remove emissions from its operations. Pioneered by LATAM Airlines Group and its affiliates, it is the collaboration with Airbus that is helping reach sustainability goals. It is important that all share the same environmental goals and participate in reducing carbon emissions together.

Day 2: Alabama workforce programs are building early aerospace talent pipelines – representing the Flight Works Alabama education center that opened about 2 years ago near the Airbus manufacturing plant in Mobile, Alabama, the team highlighted their training program for high school seniors that covers skills and certifications for a career in aviation called FlightPath9. It is nice to see Alabama represented at this international level. Day 2 also included appointments with defense contractors Kratos and Raytheon.

Day 3: There was an announcement that Boeing signed a Memorandum of Understanding (MOU) with Azerbaijan Airlines for 4 more 787-8 Dreamliner aircraft. Azerbaijan Airlines will receive 10 new Dreamliners by 2030. It was anticipated that there would be an announcement from Air India, but that expectation was not met at the Air Show.

Day 4: LATAM Airlines added 17 A321neos to its Airbus order book including the A321XLR. This is a combined total of 100 A320neo family aircraft on order with Airbus. On day 4, Qatar Airways ordered 25 B737 MAX 10 aircraft. In addition, Boeing added Qatar Airways to its MAX10 family of airplanes.

Day 5: Wrapping up a week of high-flying fun, Day 5 brought a flying display, thoughtful moments and Airbus displayed its diversity. An aerospace Q&A took place on the final day of the airshow as well.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The aerospace industry is seeing increased demand as many home-bound people are looking to travel after being quarantined for so long. With supply chain issues still being experienced by many aerospace companies, the 3D printing industry will be one of the most important technologies used to overcome those challenges.