SPONSORED CONTENT

The long line of Ender-3 3D printers from Creality has a new flagship model, the Ender-3 S1 Pro.

Each model of Ender-3 has successively offered new features, and the latest Ender-3 S1 Pro is no exception.

So what’s new on the Ender-3 S1 Pro? Let’s take a look at the major features.

This single-nozzle 3D printer has a generous build volume of 220 x 220 x 270 mm, and you’ll find a magnetically attached spring steel coated plate as the build surface. This plate’s PEI coating is able to provide proper adhesion for a variety of commonly used 3D print materials, including PLA, ABS, PETG, PA, TPU and some composite materials like wood-reinforced filament.

The 4.3-inch touch screen offers an efficient user interface and is easy to use. The interface is able to communicate in nine different languages. It will automatically dim for energy-savings if left idle for three minutes.

Automatic leveling on the Ender-3 S1 Pro is powered by the CR Touch sensor, as 16 measured points on the heat bed allow for quick compensation of the printing height, which is quite a time saver over manual leveling.

The Ender-3 S1 Pro also includes silent printing by using special stepper motor drivers and a quiet 32-bit mainboard, which effectively eliminates operating noise. It’s possible to use the Ender-3 S1 Pro in office, school or home environments without without noise impacts.

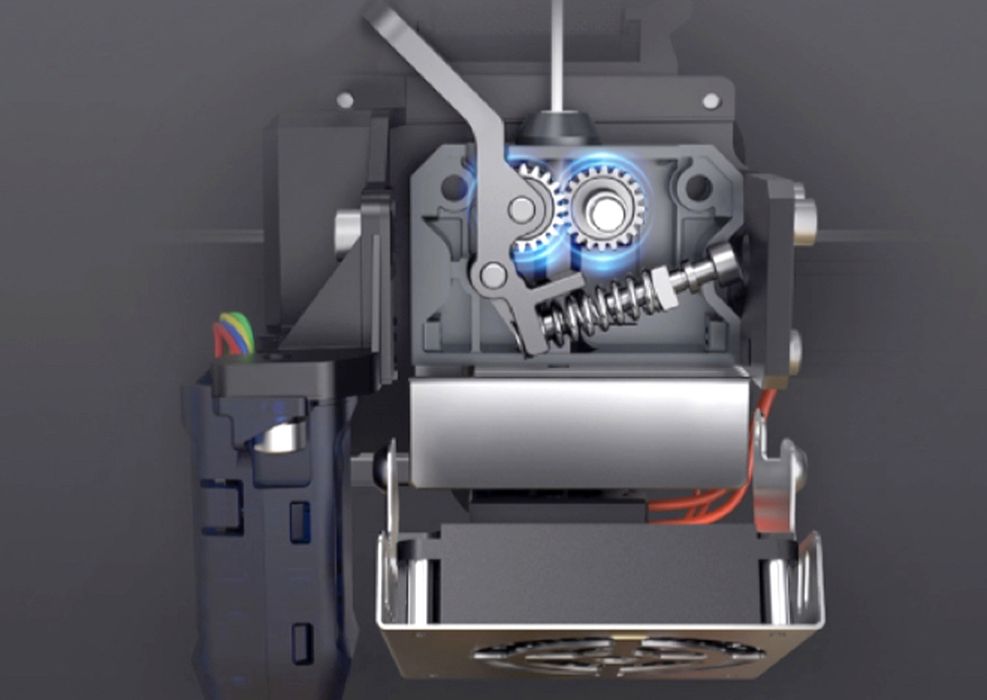

The most important upgrade to this 3D printer is the extrusion system. The extruder component is Creality’s new “Sprite” extruder, which, unlike most of their previous extruders, is a direct extruder. This has some important advantages over the usual Bowden extruders, most notably the ability to 3D print flexible materials like TPU far more easily. The Sprite also uses a dual toothed gear to very firmly grasp filament. In fact, Creality said the extruder can pull with a force of 80N, and that’s pretty significant.

The 3D printer can maintain excellent performance when operating at 300C, and that allows easy use of high temperature filaments, like polyamide (nylon).

The other part of the extrusion system is the hot end, which has also been improved. This is an all-metal affair, with brass being used throughout. This allows the hot end to be heated all the way up to 300C, far more than other hot ends that include a PTFE tube. PTFE has a thermal limit of only 260C, above which noxious fumes can be emitted. Temperatures higher than 260C are easily attainable on the Ender-3 S1 Pro because of this new hot end system, allowing the use of more engineering materials.

One interesting addition by Creality is an LED light strip along the top of the machine to illuminate the print action.

Creality Box 2.0, an optional WiFi accessory unit, supports cloud slicing and remote printing on the Ender-3 S1 Pro. Together with a camera, operators can check on a print job at anytime and from anywhere. The system also permits sharing of short print videos videos on social media platforms with friends.

It is possible to unlock additional creation potential by adding the optional laser engraving module for cutting and engraving capability, as well as an optional liquid cooling heatsink for more effective heat dissipation.

The Ender-3 S1 Pro is shipped partially assembled in an efficient flat pack, and you’ll have to put it together yourself. This is actually quite easy to do, because 96% of the Ender-3 S1 Pro is already assembled, the the remainder can be done with only six simple assembly steps. Most operators should have no issues when building the Ender-3 S1 Pro.

Meanwhile, the Ender-3 S1 Pro is now available for order from Creality directly at a good price of US$479.

Via Creality