SPONSORED CONTENT

Did you know that Creality also makes laser engravers?

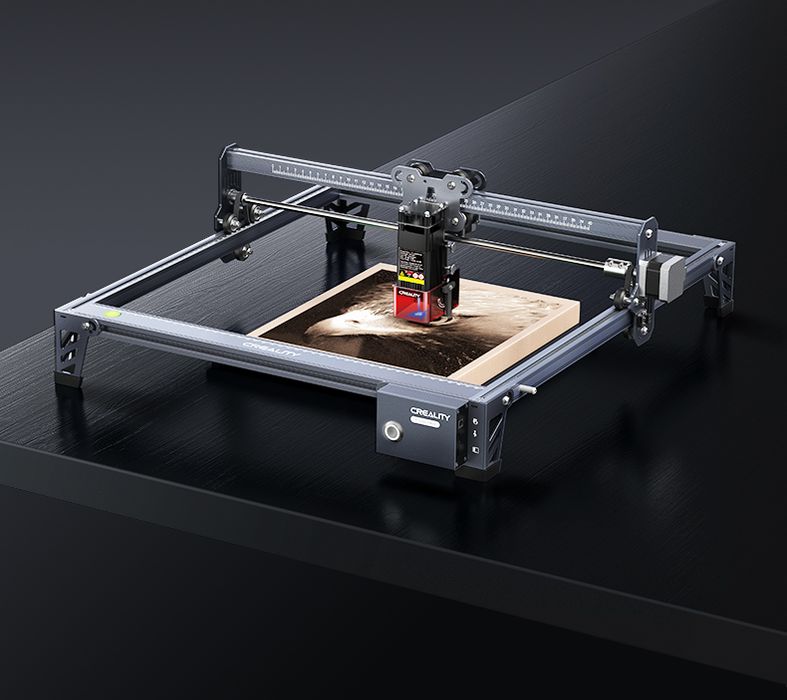

We normally write about 3D printers on this publication, but Creality asked us to take a look at their new CR-Laser Falcon Engraver, which actually has a connection to 3D printing.

One of Creality’s more recent products is the popular Creality Ender-3 S1 3D printer, a device that we are currently testing — stay tuned for a review coming soon. This 3D printer has an optional laser module that can be swapped in for the 3D print toolhead, converting the Ender-3 S1 into a small laser engraver.

It turns out that Creality saw significant interest in this feature, so they decided to produce a standalone laser engraver using the same module. This is the CR-Laser Falcon Engraver.

The CR-Laser Falcon Engraver is capable of marking flat material with complex patterns, and is even able to cut certain materials with its 5W laser.

In the world of industrial lasers, 5W is not particularly powerful. However, 5W is quite a bit more than many other desktop laser systems and 3D printer add-ons that tend to be in the 0.5 – 2.0W range. This means that the CR-Laser Falcon Engraver can cut and engrave more quickly than most similar products.

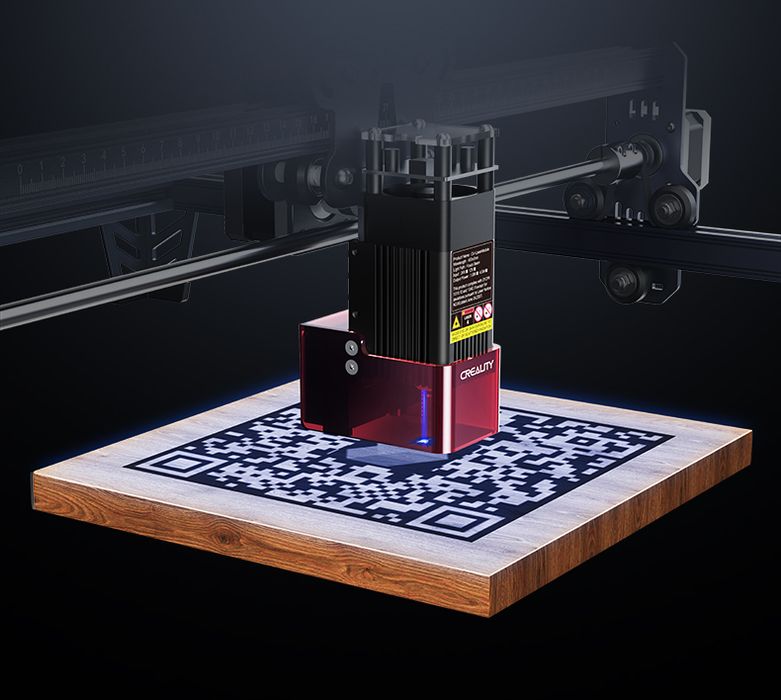

In addition to the power increase, Creality has added a special lens system that compresses the laser dot by almost 4X, placing far more energy in the active area. This significantly increases the effective power of the system, again speeding up operations.

The CR-Laser Falcon Engraver is a tabletop affair, and shipped as a kit. It’s relatively easy to assemble as their are only five main parts to deal with, along with some basic cable plugins.

Laser systems are a bit different to operate; you must position the material properly, select the appropriate power level and movement speed in order to have a successful cut. The CR-Laser Falcon Engraver provides some assists to make this a bit easier on the operator.

For example, it provides a blue light preview of the job before running, so that you can ensure it is correct. This is quite important, as a failed laser job means you lose one piece of material and have to start over. The preview feature alone should save the operator from unnecessarily wasting materials.

The CR-Laser Falcon Engraver is able to automatically focus the laser on the material’s surface. This is important because materials can be of different thicknesses, and thus the required focal point can be at different heights depending on the job.

The system also seems to have an ability to recognize material position for repeated jobs, which is frequently the case in laser work where you are producing a quantity of items.

A word about safety: laser engravers do produce smoke as they operate, and the smoke must be removed from the area, preferably by external ventilation. The CR-Laser Falcon Engraver does include a fan and filter, but to be on the safe side, I would recommend additional ventilation if possible.

The CR-Laser Falcon Engraver can work with a wide variety of materials, so long as they are flat and can be placed under the machine. The most commonly used materials are paper, cardboard, wood and leather, but it’s also possible to etch and even cut certain plastic materials. Anodized metal can be etched, but the CR-Laser Falcon Engraver is not powerful enough to cut metals.

Another safety note: please be extremely cautious when selecting plastic materials for engraving. Some materials can emit toxic chemicals when heated, or even catch on fire. Some materials emit particles that can accumulate on the laser lens system and can result in equipment damage. These materials should be avoided. A good resource for identifying questionable materials is here.

With its notable power and speed, the CR-Laser Falcon Engraver could be ideal for low volume production. With a stack of material, an operator could relatively quickly mark & cut finished pieces, perhaps able to make dozens of parts in a day, depending on the nature and size of the design.

Creality has provided us with a discount code valued at US$30, which reduces the price of the CR-Laser Falcon Engraver when purchasing. The device is also available on Amazon now.

The CR-Laser Falcon Engraver is surprisingly inexpensive, at only US$349. From my experience using laser systems, it should be straightforward to recoup the cost of this system by simply producing small items for sale with the system’s speed. It’s even possible you may be able to make money using this device!

Via Creality