Management Execution Systems make things easy, but under the covers there are many challenges.

A management execution system, or “MES”, is a software tool that, as you might expect, manages the execution of 3D print jobs. Some of the most typical functionality could include:

- Accept incoming jobs and place them on a queue

- Dispatch jobs to available 3D printers

- Monitor the status of a group of 3D printers to know which are available and which are busy

- Collect statistics on printer usage and reliability

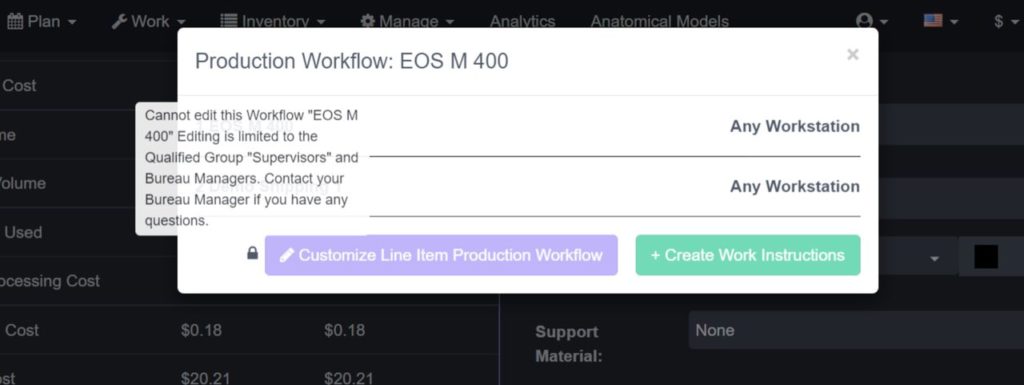

- Implement a custom workflow for print jobs

- Provide alerts if problems are encountered

- Provide notifications when jobs complete

These functions would be used by a 3D printer operator to increase efficiency. For example, instead of having the operator start each and every job, the operator could maximize their time removing completed jobs and repairing broken machines. In other words, the MES automates as much as possible during 3D printing operations.

Of course, this requires that the MES have a digital connection with the machines in question.

Fortunately, most 3D printers do indeed provide such an interface, making it possible for MES software to function.

Desktop 3D printer users might be familiar with this concept: using a set-top box or PC to control a 3D printer. In fact, this capability has been exploited by Octoprint and similar systems to provide extra functionality for otherwise “dumb” desktop 3D printers.

Most industrial 3D printers have similar interface capabilities.

However, there’s a big challenge.

Where desktop 3D printers tend to use one of only a couple of standard firmware packages, that’s not the case with industrial equipment. The desktop standard means a project like Octoprint can easily connect with dozens of different 3D printers simply because they all use the same firmware options.

But if you’re dealing with industrial 3D printers, that’s another story.

Additive manufacturing workshops now tend to have a variety of equipment present in order to cover off more possibilities. A given print job might be best 3D printed on one type of device, so having multiple device types is the way many workshops are moving.

Those workshops with multiple machines and particularly those having equipment from multiple providers are the best candidates for MES software, as their complex environments deserve as much automation as can be had.

But the creator of the MES must deal with multiple APIs to each of the different systems. Each equipment manufacturer tends to make their own unique interface, perhaps due to previous system strategies where they hoped to “own” the room. The result is a that workshop with multiple equipment providers will have multiple APIs for an MES to deal with.

And it can be even worse, as an equipment provider might have multiple APIs, even for their own equipment. This can happen as new equipment offers new capabilities, but older equipment might still be present.

For an MES provider, the problem is quite tricky. If they attempt to sell their MES software to a workshop, the sale might not go through if they didn’t happen to support one or more of the machines present. Therefore it’s critical that an MES support as many machines as possible.

Authentise offers an MES, and I read their latest press release. They said:

“Over the past few years the large OEMs have been finally waking up and providing official APIs, making our job easier. We took advantage of that and are among the first to support both Formlabs Form 2 and 3 as well as most remaining Stratasys machines we didn’t already.”

I was curious. How many machines do they support? On Authentise’s web page they say they integrate with these 3D printers:

- Carbon M1

- Carbon M2

- EOS M290

- EOS M270

- EOS M400

- EOS M400-4

- EOS M300-4

- EOS M280

- EOS P500

- EOS P395

- EOS P396

- EOS P800

- EOS P770

- EOS P800

- Formlabs Form 3

- Formlabs Form 3L

- Formlabs Form 2

- HP MJF 4200

- SLM 500 MCS 3+

- SLM 280 MCS 3+

- SLM 125 MCS 3+

- Stratasys J750

- Stratasys J5

- Stratasys F123

- Stratasys Fortus 450

- Stratasys Fortus 900 Mc

- Stratasys Fortus 250 Mc

- Stratasys Fortus 450 Mc

- Stratasys Uprint

- Stratasys Dimension Elite

- Ultimaker 3+

In addition, we were told they do work with at least another 31 similar devices from 3D Systems, Arcam, Carbon, EOS, GE, HP, Renishaw, SLM Solutions, Stratasys and Trumpf, but these have not officially been tested yet.

As you can see, building an MES is not as straightforward as building the functions listed above. In fact, you have to do with for all these systems!

Imagine building interfaces for all these 60+ machines and I think you get the idea of the complexity involved here.

But that’s the price necessary to provide universal functionality for workshops operating many different kinds of devices. That style of configuration is likely to become the norm in the future.

Via Authentise