Charles R. Goulding and Preeti Sulibhavi review a webinar from the Additive Manufacturing Coalition.

On September 13th, 2022, the Additive Manufacturing Coalition presented a webinar titled “How AM Can Improve Supply Chain Resiliency”. The webinar featured panelists such as Ms. Kimberly Gibson, Ecosystem Director of America Makes, Mr. James DeMuth, Chief Executive Officer of Seurat, and Ms. Tali Rosman, Vice President and General Manager of Xerox Elem Additive.

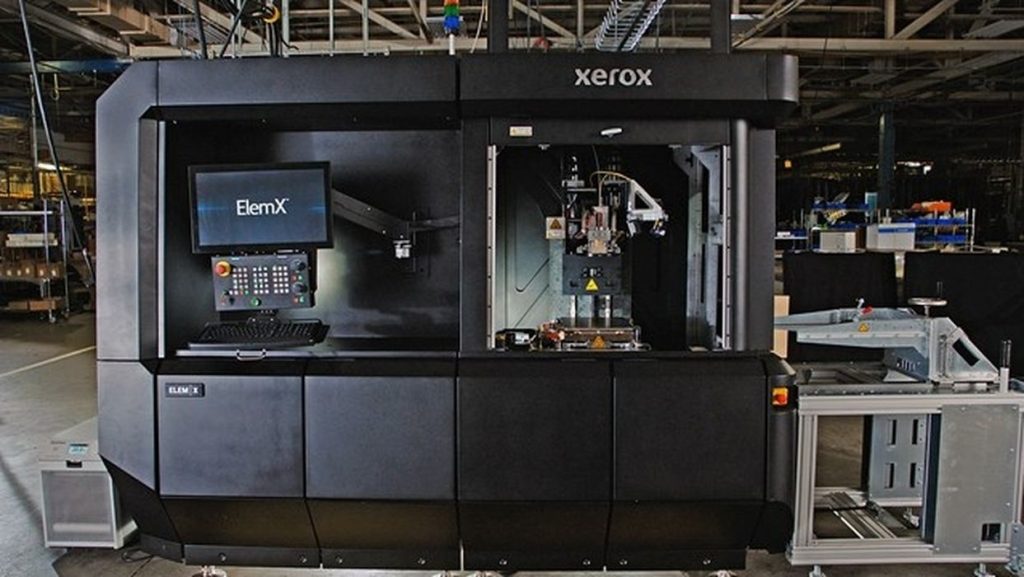

Xerox Elem Additive installed a Xerox ElemX™ 3D Metal printer at the Department of Energy’s Manufacturing Demonstration Facility (MDF) at Oak Ridge National Laboratory (ORNL). The 3D printer utilizes cost-effective aluminum wire and requires no special facility modifications for operation. It is easily deployed and provides faster time-to-part. The printer is depicted below.

Seurat Technologies has a proprietary area printing technique for metal 3D printing. This technique utilizes lasers to melt and then weld the melted layers of thin metal powder into the digitally designed shape that it should reflect. The laser is patterned with high-resolution images that can be programmed to block or let light through each pixel. As layers accumulate a product emerges.

The webinar covered various key items about AM and its benefits. Widely used was the term “hybrid solutions,” which would boost domestic production while procuring materials via shipping of commodities with the preferred mode of transport being railways. As we know, 3D printing offers low-cost solutions often with quicker turn-around times, it boosts domestic employment and of course, offers supply chain resiliency.

The webinar illustrated how serious the US Department of Defense is taking AM. The USS Essex has become the first US Navy ship to have a 3D printer onboard where the capabilities of 3D printing at sea are being tested.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

“With Great AM Power Comes Great Production”

This webinar was insightful for anyone interested in advancing their technological understanding of our current supply chain conundrum. 3D printing offers global solutions to critical manufacturing issues.