Tethon 3D is getting into the dental business.

The Omaha-based company specializes in 3D printer resins, and in particular, ceramic resins.

Ceramic resins are one of the lesser known capabilities of most resin 3D printers. The ceramic resins are actually a mix of a photopolymer resins and a ceramic powder. After printing it is possible to post process the print with heat treatments to burn out the polymer and leave a solid ceramic object.

Tethon 3D has long produced such resins, and even offers the ability to produce custom resins with different ceramic materials and ratios.

Their product catalog is quite extensive, and a perusal shows all manner of unusual ceramic materials, including mullite, porcelain, glass, graphene, cordierite and others, well beyond the usual zirconia and alumina materials offered by most ceramic 3D printing systems. The company also offers a few other unusual resins, such as a flexible material, carbon nanotube resin, investment casting resin, and a highly unusual iron resin.

How do they produce these unusual materials? It’s all about material ratios, where the polymer is reduced in proportion to the added ingredient. Tethon 3D told me they can achieve 75% “ingredient” by volume or up to 90% by weight.

I was a bit skeptical about the 90% weight claim, but soon changed my mind as we picked up a bottle of their new Zircolite material. The bottle was incredibly heavy, like picking up a rock of that volume. The weight, of course, is all the zirconia particles mixed in with the resin.

A few years ago Tethon 3D introduced a resin 3D printer of their own, the Bison 1000, which uses a DLP light engine to polymerize resins.

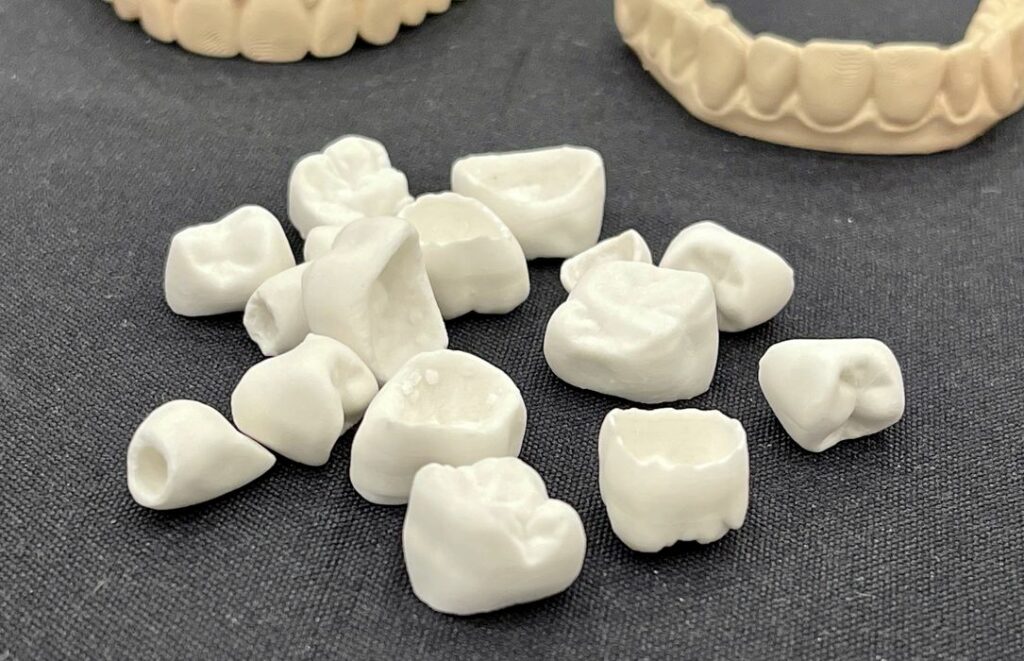

The news is that they’ve developed a ceramic resin that’s suitable for the dental industry. It’s a proprietary material used to produce dental crowns. This is quite interesting, because few dental 3D printing systems can produce crowns, which must be made from extremely hard and durable material. The crowns look pretty good to me, and potentially could enable dental offices to 3D print them directly on site, if they had the equipment.

That’s where I believe this development is headed. I got the impression from speaking with Tethon 3D that they intend on launching a dental 3D printer of their own, which could be a modified version of their Bison 1000 3D printer.

This is an exceptionally good move for Tethon 3D, as the dental market is huge and will last as long as people have teeth. There’s also the fact that dental procedures and parts are already priced high, so it’s a natural fit for 3D printing. It adds another very large market to their existing institutional market that often uses their equipment and materials for material research programs.

Via Tethon