voxeljet announced the sale of a 3D printer. But it’s more than just that.

What’s the big deal about a single sale of a single 3D printer? Don’t some manufacturers sell tens of thousands of 3D printers per month?

Well, yes, some manufacturers do sell that many and more. But in these matters, size counts.

The high-volume 3D printer sales are always low-cost, desktop devices, typically priced in the low hundreds of dollars.

Here we have the exact opposite end of the spectrum: voxeljet produces some of the very largest 3D printers on the planet. They don’t sell nearly as many of these devices, but when they do, a lot of money changes hands. It’s a low-volume, high-margin business.

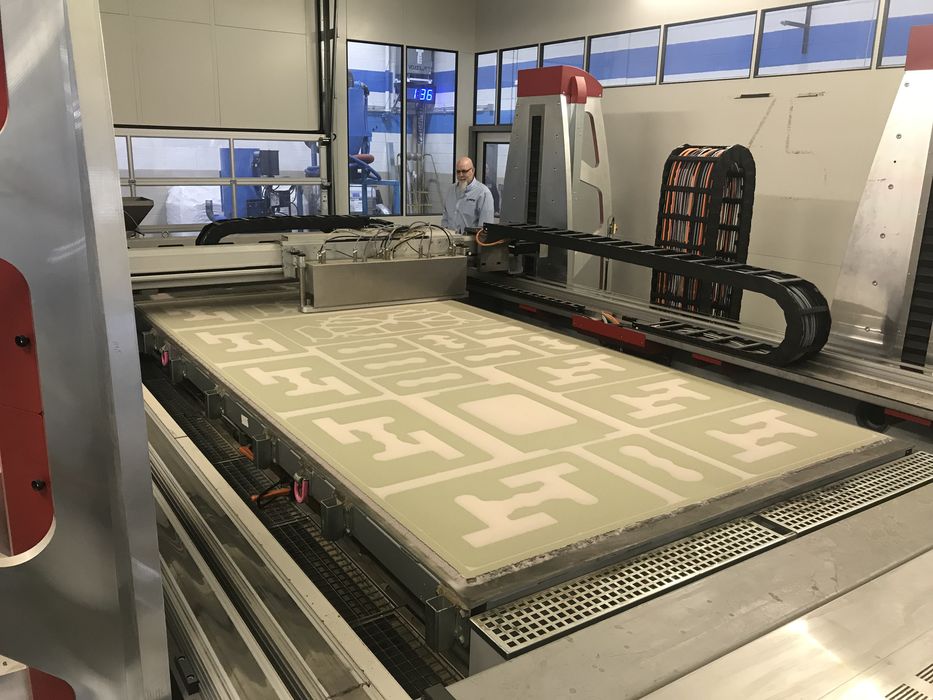

Most of their machines are sand 3D printers. These are used to create molds for casting metal into industrial parts. The metal is poured into the 3D printed molds, and cooled. Then the molds are destructively removed to reveal the new metal cast parts.

The machine in question is the voxeljet VX4000, the absolute largest device from the company, with a whopping build volume of 4000 x 2000 x 1000 mm. Let’s just say that again in meters: 4 x 2 x 1 m. The smallest dimension on the VX4000’s build volume is very likely multiple time larger than on any device you operate.

voxeljet said a new VX4000 had been purchased by Tooling & Equipment International (TEI) to supply parts to their customer, General Motors.

GM intends on using TEI’s services to produce large, lightweight parts for their Cadillac CELESTIQ automobile. The VX4000 is so large that voxeljet said TEI could print “hundreds of inner cores” overnight, adding quite a bit of part production capacity.

voxeljet explains how TEI will use the 3D printer:

“The novel underbody structure consists of six large precision sand-cast aluminum parts. In order to realize the complex structures as economically and lightly as possible, TEI uses additive manufacturing in production for all inner cores. This allows stiffening features to be incorporated into the hollow sections, which is not economically feasible with conventional manufacturing. A total of 51 additively manufactured sand cores are used in the production of each vehicle underbody. TEI prints these using the VX4000 printers, each of which prints hundreds of inner cores for several vehicle sets in just one night. After printing, the cores are smoothed, coated with a fireproof coating, placed in sand molds and finally cast using a low-pressure filling process. Each of the six castings reduces the number of parts by 30 to 40 components compared to a typical stamped construction. As each structural part has fully machined interfaces, the six castings can be assembled precisely and very tight tolerances can be maintained for assembly fabrication.”

It turns out that TEI has used the VX4000 previously: they already own two of the massive devices, and with the new purchase, they will operate three. According to voxeljet, they are the only company in North America to operate three VX4000s.

This is certainly a very positive sign for voxeljet, as a demonstration of confident production by a major manufacturer could push up the voxeljet’s valuation, and attract additional production applications.

Via voxeljet