We had a look at Flashforge’s latest professional 3D printers, the Creator 4 and Guider 3.

Flashforge, one of the pioneering manufacturers of 3D printers, has always provided a diverse range of equipment for a myriad of applications. We recently got an opportunity to delve into their latest offerings in the professional market, the Creator 4 and Guider 3.

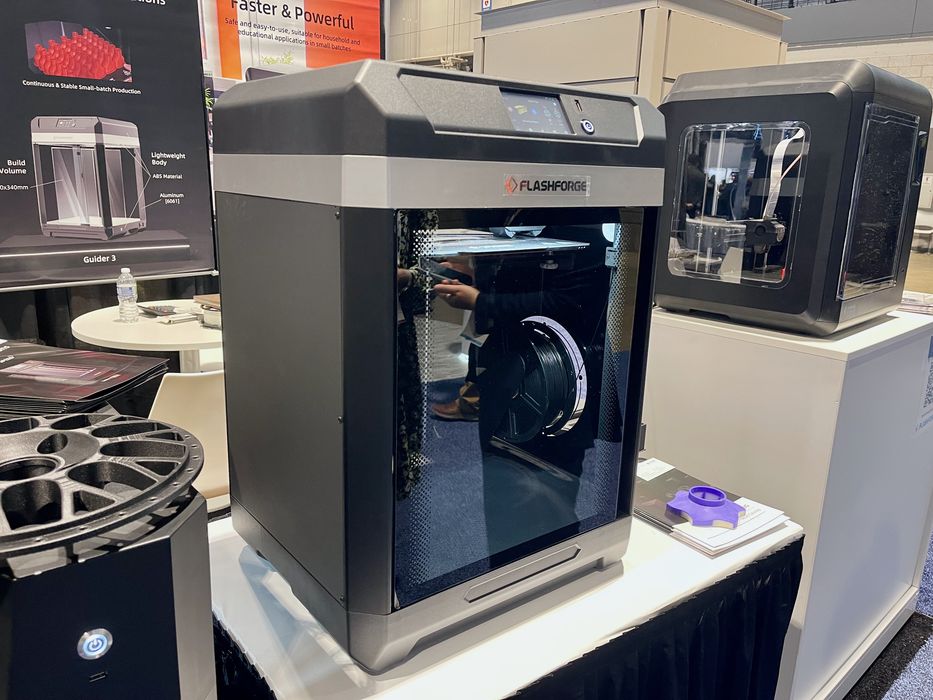

A Deep Dive into the Creator 4

Beginning with the Creator series, these printers cater to the professional market through key features like an enclosure and connectivity. The latest addition to this series is the Creator 4. Boasting a hefty build volume of 350 x 400 x 500 mm, the Creator 4 is anything but small. This size allows the creation of impressively large objects.

The heart of the Creator 4 lies in its extrusion system – a dual independent, or “IDEX” setup. But the real kicker? These toolheads are not just independent; they’re specialized. Flashforge offers three unique toolhead types:

- Extruder-F for flexible filament

- Extruder-HT for high-temperature engineering filament

- Extruder-HS for carbon fiber composite

In combination with the enclosed build chamber, this system enables the Creator 4 to print a broad range of engineering materials effortlessly. The IDEX configuration facilitates the use of soluble support, paving the way for complex geometries without a hitch.

One intriguing optional feature is a filament drying unit that can be conveniently placed underneath the printer, ensuring optimal humidity levels for the materials before printing starts.

A Quick Peek at the Guider 3 and Guider 3 Ultra

Next, we took a brief look at the newest Guider 3 models: the Guider 3 and its bigger sibling, the Guider 3 Ultra. While the base Guider 3 has a smaller build volume of 300 x 250 x 340 mm, the Ultra version takes things up a notch at 350 x 350 x 600 mm.

Both machines come with a 320C hot end, suitable for various engineering materials. Additionally, they sport an onboard camera system for remote monitoring and control via the Flashpoint 5 software app. The Guider 3 is capable of achieving a relatively high printing speed of 250mm/s.

The Guider 3 Ultra, with its towering stature, utilizes a coreXY motion system design to reach the 250mm/s high print speed. According to Flashforge, the machine’s design can reduce noise by about 30%. This model is also built for 24/7 use through high-precision mechanical components and can accommodate two 1kg spools in an onboard passive drying system.

Conclusion

Flashforge seems to have invested significant effort in designing these 3D printers to produce high-quality parts. These professional printers, with their robust features, are well-equipped to handle a wide range of tasks, even producing end-use parts.

Via Flashforge