Sygnis has obtained a license to commercialize the L-FDM 3D printing process.

What’s L-FDM, you ask? It stands for “Liquid Fused Deposition Modeling”, and it’s a variation on the original FDM (FFF) process for filament 3D printing.

The goal of L-FDM is to efficiently introduce additives into the material used by a FFF (or FDM if Stratasys equipment) 3D printer.

What kind of additives are we talking about here? They could be many forms:

- Colors and dyes

- Electrical conductivity

- Strengthening agents

- Magnetic properties

- Environmental resistance

- Chemical reactions

These and other additives would supercharge material capabilities on 3D printers, making it possible to create many unique parts and applications.

But how, exactly is this done? And how can it be efficient?

Their approach is ingeniously simple and actually possible to implement on even the most basic 3D printers. The associated research paper describing L-FDM actually used a Creality Ender 3 and Prusa MK3S for their successful experiments.

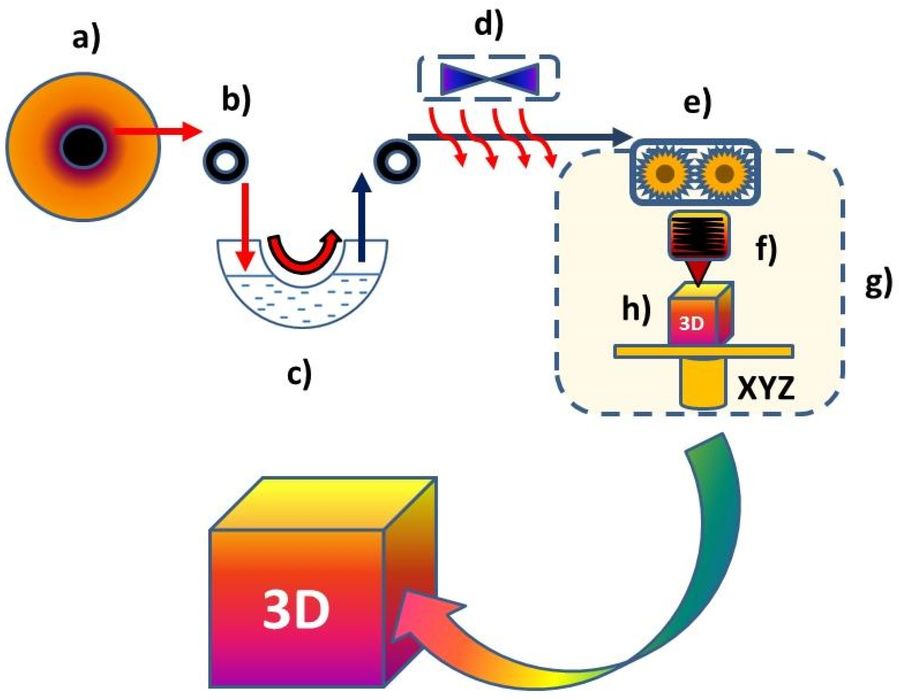

The concept is to pass the 3D printer filament through a liquid batch containing the additive. This liquid coats the filament, which then travels to a drying stage. At that point we have a filament coated with, well, whatever you require.

The filament then proceeds into the normal hot end of the 3D printer and is mixed in with the core of the filament as usually occurs in the hot end. The resulting 3D printed part has more-or-less uniform distribution of the additive.

The researchers tested the approach with not only different commonly available 3D printers, but also with different materials. Tested in their experiments were PLA, PETG, ABS, ASA and others, including wood filament. The paper shows success in these experiments, proving the concept works.

What’s most interesting about this approach is that it is incredibly simple and therefore would be low cost. In addition, it could be implemented as an add-on accessory for existing 3D printers since it is external to the 3D printer itself.

There are more ways to deploy this approach. In addition to coating the filament on the way to the hot end, it’s also possible to spool up an entire reel of coated filament. Then it would be possible to run that filament through a second bath to place a second additive on the filament. This could be repeated a few times to provide an ability for multiple additives.

This is quite a development, and I can see this being used in a number of ways, particularly by researchers investigating new devices and applications.

I’m not so sure this would be particularly useful for color 3D printing, however. Color printing requires an ability to quickly change colors during the print job, and that doesn’t seem to be what this system would do.

The news is that Sygnis has signed a licensing agreement with the inventors of L-FDM from Adam Mickiewicz University. This permits Sygnis to develop solutions with the technology for up to ten years, while providing royalty payments back to the inventors and University. It seems that the license applies to Poland, so it’s possible this technology could appear elsewhere with other providers.

Nevertheless, this could be a very important technology for FFF devices going forward.

I would like to know what a license means, cause the concept have been known on youtube for years, so it cant be patented! Is the license from Stratasys?