Velo3D announced a new metal 3D print material, but there’s more to the story.

You’d think the announcement of a certification for a new material on a 3D printer would not be news, but I believe there’s a bit more going on here.

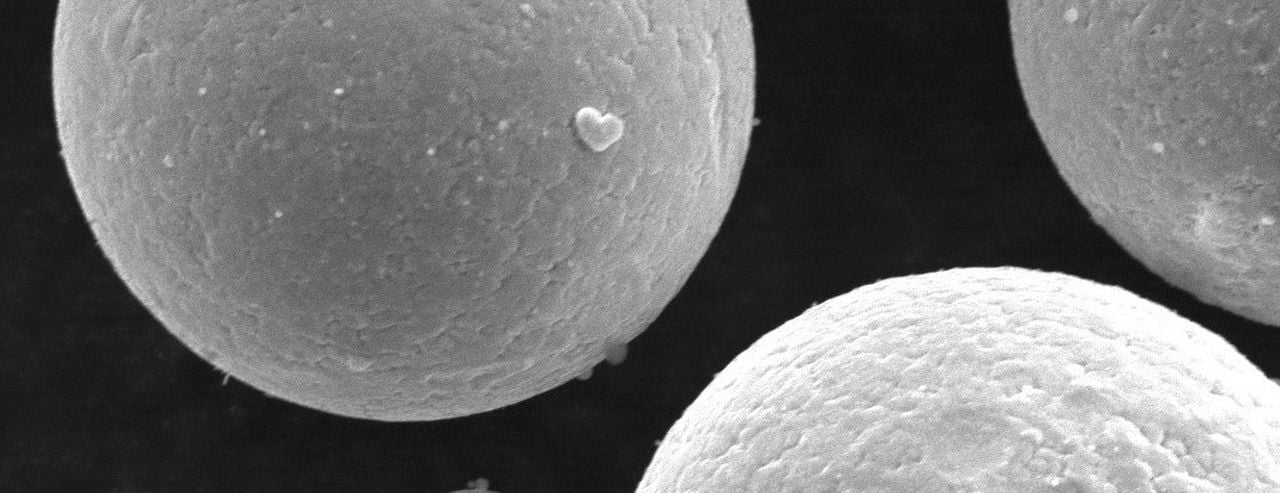

What was the news? Velo3D announced they’ve certified OptiPowder 718 for their Sapphire line of metal 3D printers. OptiPowder 718 is produced by Continuum Powders, a company specializing in recycled metal powders.

Optipowder Ni 718 is a nickel-based superalloy made from a list of eight six elements in specific ratios. It’s said to be ideal for extreme environments where corrosion resistance, strength and hardness are required. Continuum Powders explains:

“The properties of 718 make this material attractive for applications such as aerospace structural components, rotating parts in LPT and HPT sections, spacers, bolts and fasteners. The material is also beneficially applied in Industrial Gas Turbines, liquid-propelled rocket motors and combustion chambers, fuel cells such as solid Oxide fuel cells and under-sea tubing for oil gas.”

That all sounds quite normal, except for one thing: this is a sustainable material. Continuum Powders writes that their metal powders are:

- 100% From secondary raw materials

- 100% Recyclable

- 100% Traceable

- 100% Compact and local

- 100% Produced with green power

That cannot be said of almost every other metal powder.

Velo3D explained that Optipowder 718 is the very first sustainable material certified for use on their equipment. The question is, why would Velo3D promote this aspect so prominently?

My suspicion is that they have been increasingly receiving requests from customers seeking sustainable materials for their prints. In the world today there is an increasing demand for sustainable products as we gradually eat up the Earth’s resources.

Product customers more frequently select products made from sustainable sources, and that demand cascades upwards from the product manufacturer to the 3D printer maker. In this case, it’s Velo3D.

Velo3D has reacted by certifying a sustainable material. This makes their system just a bit more attractive for buyers that know they will be required to produce sustainable parts on the equipment.

My expectation is that Velo3D and other metal 3D printer manufacturers will announce certification of further sustainable materials. At some point we may see sustainable materials as the default option for materials on these machines.

That’s a good thing.

Via Velo3D and Continuum Powders