Prusa Research released the latest beta version of PrusaSlicer, and surprise — it includes the ability to use STEP files.

As an open source software product, Prusa Research posts updates to GitHub where anyone can use the code and observe changes in releases. The company is constantly updating PrusaSlicer, so a new update isn’t necessarily a big deal. But this one is. On GitHub, they explain:

“Starting with this release, PrusaSlicer is able to import STEP files, which is a format widely used for 3D modelling data exchange. Note that the model is tessellated on import and the slicing algorithms operate on the resulting triangle mesh, i.e., the model is not sliced analytically.”

What is a STEP file? Many typical Prusa 3D printer operators might have never seen or heard of this file format, so let me explain.

Most operators simply use a CAD tool to design their object, then export “STL”, or more recently “3MF” files that are then sliced in PrusaSlicer for printing. These are often called “meshes”, as they describe a mesh-like net that would fit around the object like a skin. There is no information about the “inside” of a mesh object. There is normally no need for STEP files.

However, in the industrial CAD world, STEP files are critical: they are the universally accepted method of exchanging CAD designs between tools, each of which typically uses their own proprietary file format for storing designs. One team using SOLIDWORKS could export STEP files and have the other team using CATIA could import the files and continue working on the design.

By “designs”, I mean the instructions required to create the 3D object: extrude a cylinder, draw a line, loft between these surfaces, fillet this edge, etc. The CAD file includes these instructions so that you can, for example, “undo” a change by backing up an instruction or two.

That editing capability is not present on STL files, as they simply describe the “surface” of the object. There is no way to, for example, change the diameter of a hole in an STL file because you would literally have move hundreds of tiny triangles. But a CAD tool can do so easily.

Meshes and CAD files are utterly different, but both describe a 3D object.

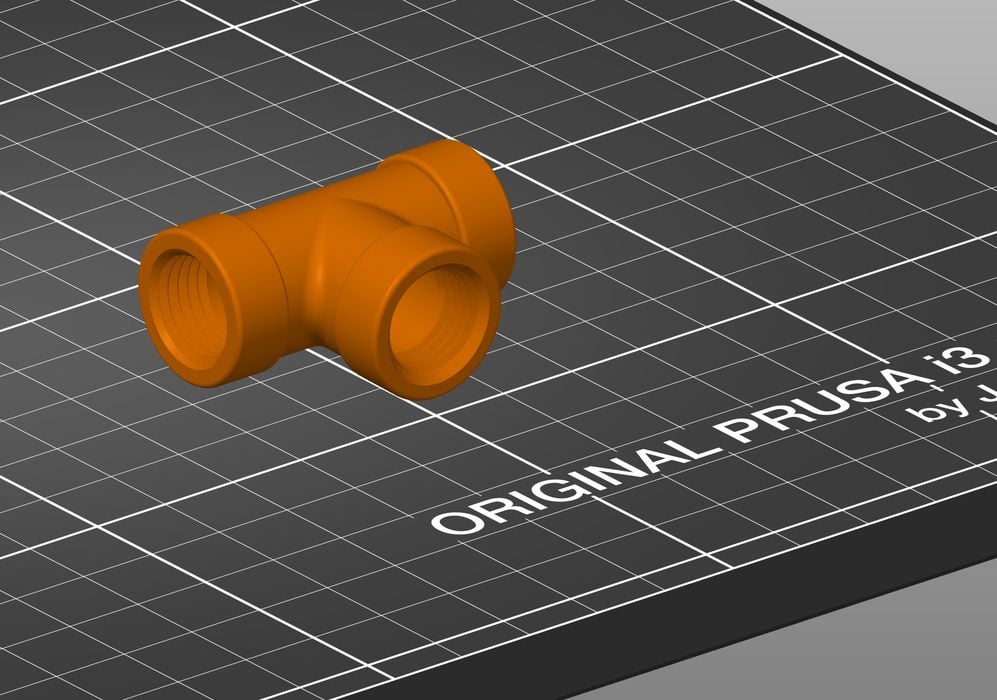

The news here is that PrusaSlicer 2.5.0 beta can import STEP files as well as the usual STL and 3MF formats.

Prusa Research is using Open CASCADE Technology to interpret the incoming STEP files and transform them into meshes that can then be sliced in the usual manner. This approach is used by several other open source 3D tools, and Prusa Research themselves used import code from BambuStudio to kick start the development of this feature.

For many Prusa 3D printer operators, this announcement might be a nothing burger: they will continue to use STL or 3MF in their 3D print workflows. There could be a small benefit to them in that some 3D model repositories include objects only in STEP format, which could now be directly sliced in PrusaSlicer. More pre-made objects could be used.

But those operators are not the main target of this feature.

Instead it’s the professional and industrial 3D printer operators.

Imagine an industrial 3D print workflow: using SOLIDWORKS and normally saving in STEP format for team use, exporting to STL, importing and slicing, then printing.

The introduction of this new feature allows those industrial operators to perhaps skip an export “step” and directly use the STEP files they may already have for part designs. Simplifying workflows is always a good thing.

This is fabulous news for Prusa Research’s industrial and professional customers.

And especially for the new industrial and professional customers they don’t even have yet, those who would be attracted by this feature.

What Prusa Research has done here is continue positioning PrusaSlicer as a proper industrial tool. As I’ve previously written, I believe Prusa Research is slowing moving into the professional and industrial space to avoid future competition with low-cost providers. This software change is very clearly part of that strategy.

Why so? If a company is considering professional 3D printing gear, they will certainly have a long list of qualifications that vendors must meet in order to be considered. One of the ticky boxes on that list is “Ability to handle STEP files”.

Item ticked.

Via GitHub