Charles R. Goulding and Preeti Sulibhavi examine a tragic applications of 3D printing and consider how things could have worked out for the better.

For Dr. Paolo Macchiarini and his ground-breaking 3D printed artificial windpipe, the world was once his to conquer. This is until he lost a court ruling in Sweden that indicted him for aggravated assault because of his novel artificial organ. Now, he has received a “conditional” or suspended sentence as opposed to the five years that prosecutors had asked the court for.

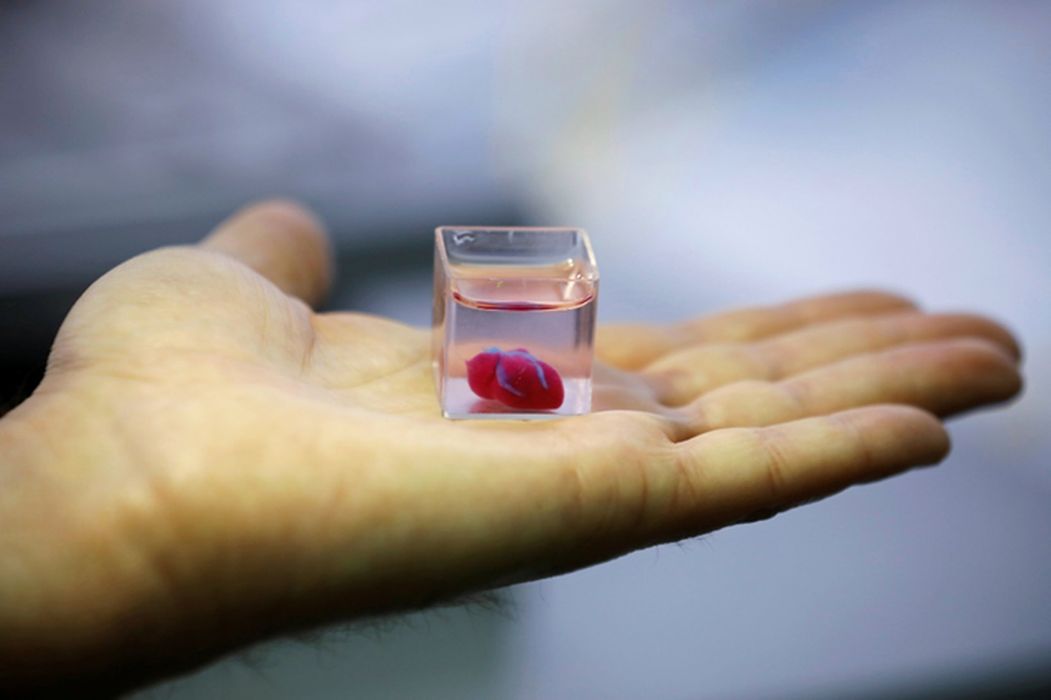

Bioprinting is not a brand new concept to the 3D printing world. It is, however, generally experimental. But medtech is pivoting towards 3D bioprinting, with many 3D companies, such as 3D Systems, focusing on accelerating the use of the technology in healthcare.

The Silicon Valley mantra “fake it until you make it,” does not apply to the med-tech industry as patients’ lives hang in the balance. What makes Dr. Macchiarini’s story interesting is that it emphasizes the fact that the med-tech and biotech industries are unlike any other, particularly in the start-up phase.

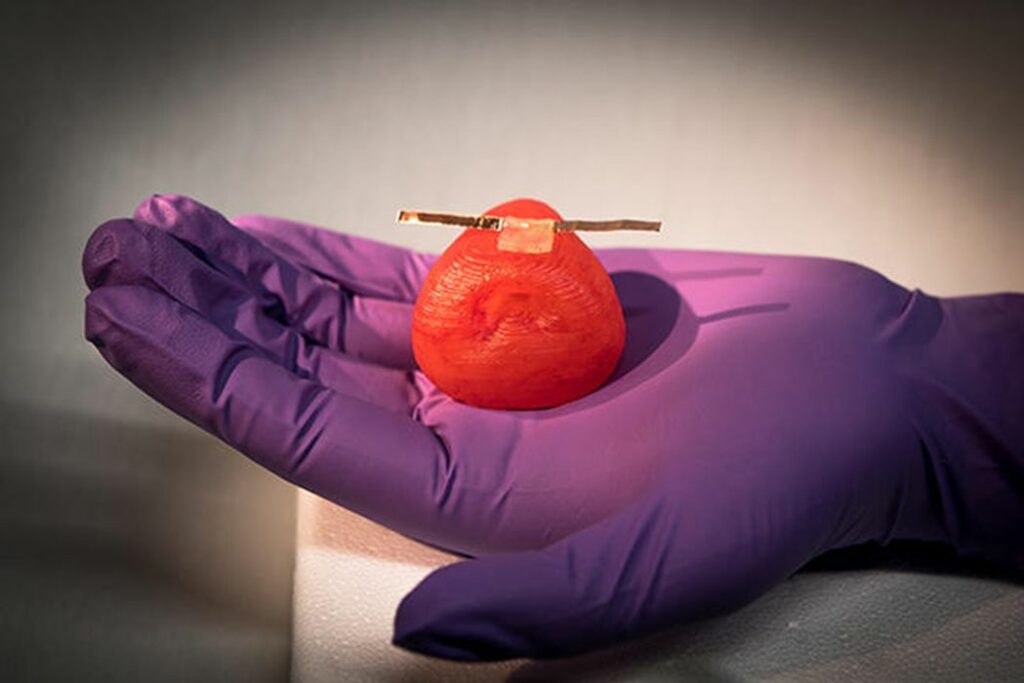

What went wrong with the world’s first 3D printed bioartificial windpipe? Some patients became disfigured with the plastic trachea and others did not take to the procedure itself, which involved replacing the damaged trachea with a plastic replica soaked in the patient’s own stem cells. All but one of Dr. Macchiarini’s patients are dead.

Many blame the Karolinska Institute as well because how it’s handled these cases and what some say is the overlooking or even covering up of some of the lethal results. While bioprinting has the potential to substantially improve patient outcomes, there still needs to be extensive research and testing before it is applied to human patients in the field.

There are many ways researchers are investigating the potential uses and functionalities of bioprinted organs. Until we attain success in studies involving human subjects, transparency and sharing of findings are the key to positive health outcomes. 3D printing can play a beneficial role in this process.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

There is a good reason why we chose to write about a failed 3D printing experiment on a 3D printing blog: to learn. What can we learn from this travesty? That 3D printing can save lives, but if used haphazardly or irresponsibly, it can be dangerous. Research and testing are critical because, in the 3D bioprinting realm, there is no room for error.